Color change and temperature sensing ribbon for electric wires and cables and manufacturing process

A cable and wire technology, which is applied in the field of the manufacturing process of the color-changing temperature-sensing cable tie, can solve the problems of poor contact between the temperature-sensing sheet and the cable, inaccurate temperature, etc. accelerated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

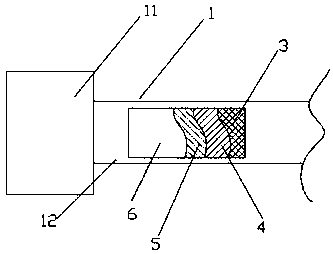

[0038] Such as figure 1 As shown, the present invention is a color-changing temperature-sensitive cable tie for wires and cables, which is characterized in that it includes a cable tie 1 and a temperature-sensitive device arranged on the cable tie 1, and the temperature-sensitive device is arranged near One end of the tie head 11 of the cable tie 1. The cable tie 1 and the temperature-sensing device are integrally formed. A cavity 3 is formed in the middle of the inner surface 12 of the cable tie 1 of the present invention, and a temperature-sensitive material 4 is filled in the cavity 3 . Black paper 5 is adhered to the outside of the temperature-sensitive material 4, and a self-adhesive layer 6 is coated on the outside of the black paper 5, and the thickness of the self-adhesive layer 6 is 0.1-0.2mm. Wherein the temperature-sensitive sheet 2 is composed of a temperature-sensitive material 4 , black paper 5 , and a self-adhesive layer 6 . In the present invention, the tempe...

Embodiment 2

[0045] The difference from Embodiment 1 is that grooves are formed on both side walls of the bottom of the concave cavity 3, which facilitates the filling and integration of temperature-sensitive materials, and the locking with each other is more firm. The temperature-sensing material on the temperature-sensing sheet is consistent with the temperature-sensing material in Example 1.

Embodiment 3

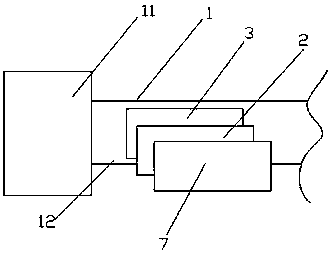

[0047] figure 2 As shown, the difference from Example 1 is that in the present invention, the cable tie 1 and the temperature-sensing device are formed separately, and the temperature-sensing device is a temperature-sensing sheet 2, wherein the cable tie 1 A concave cavity 3 is formed in the middle of the inner surface 12 of the inner surface 12, and a temperature-sensitive sheet 2 is arranged in the concave cavity 3, and glue is coated on the outside of the temperature-sensitive sheet 2 to form a glue layer 7. The temperature-sensing material on the temperature-sensing sheet is consistent with the temperature-sensing material in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com