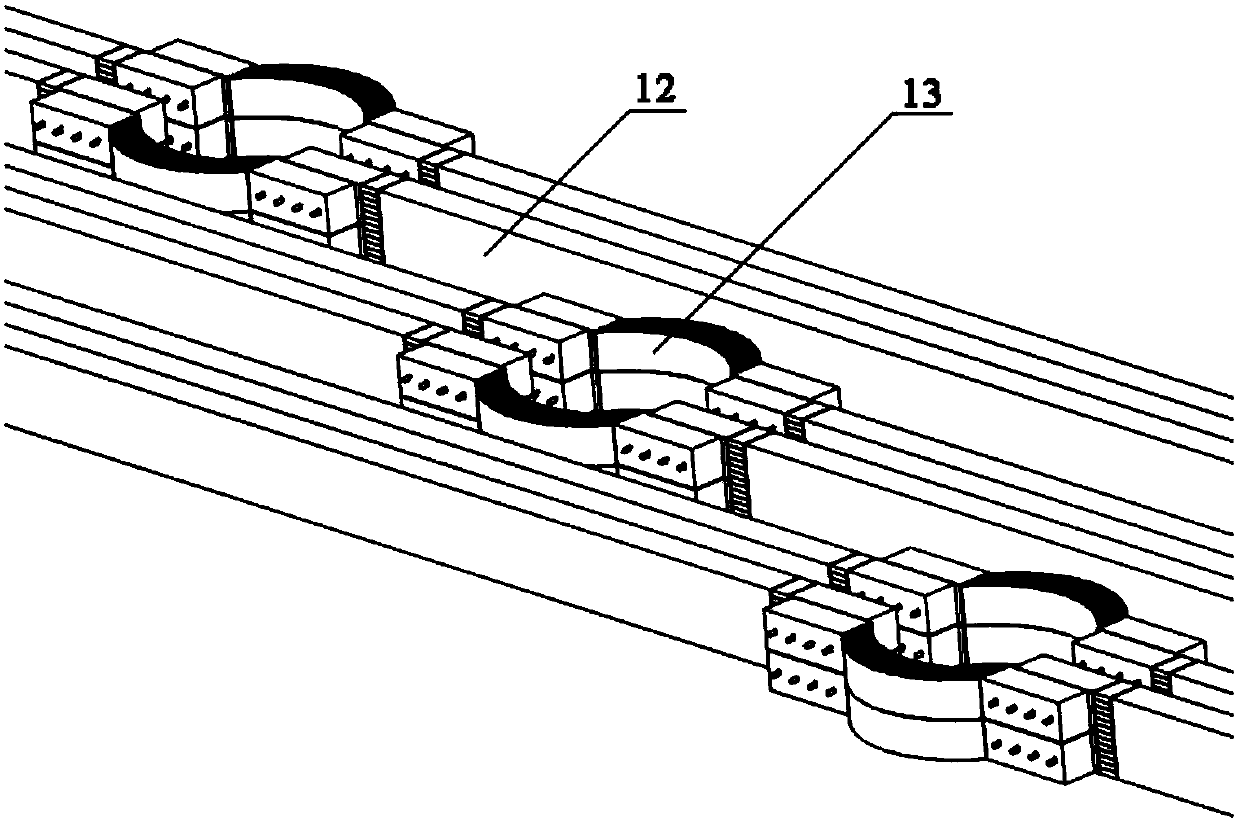

Aluminum electrolysis short-circuit bus dismounting mechanism

A short-circuit busbar and disassembly mechanism technology, which is applied in the field of aluminum electrolysis, can solve the problems of limited space, difficult access of large equipment, time-consuming and labor-intensive problems, and achieve the effect of convenient operation, safe and reliable installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

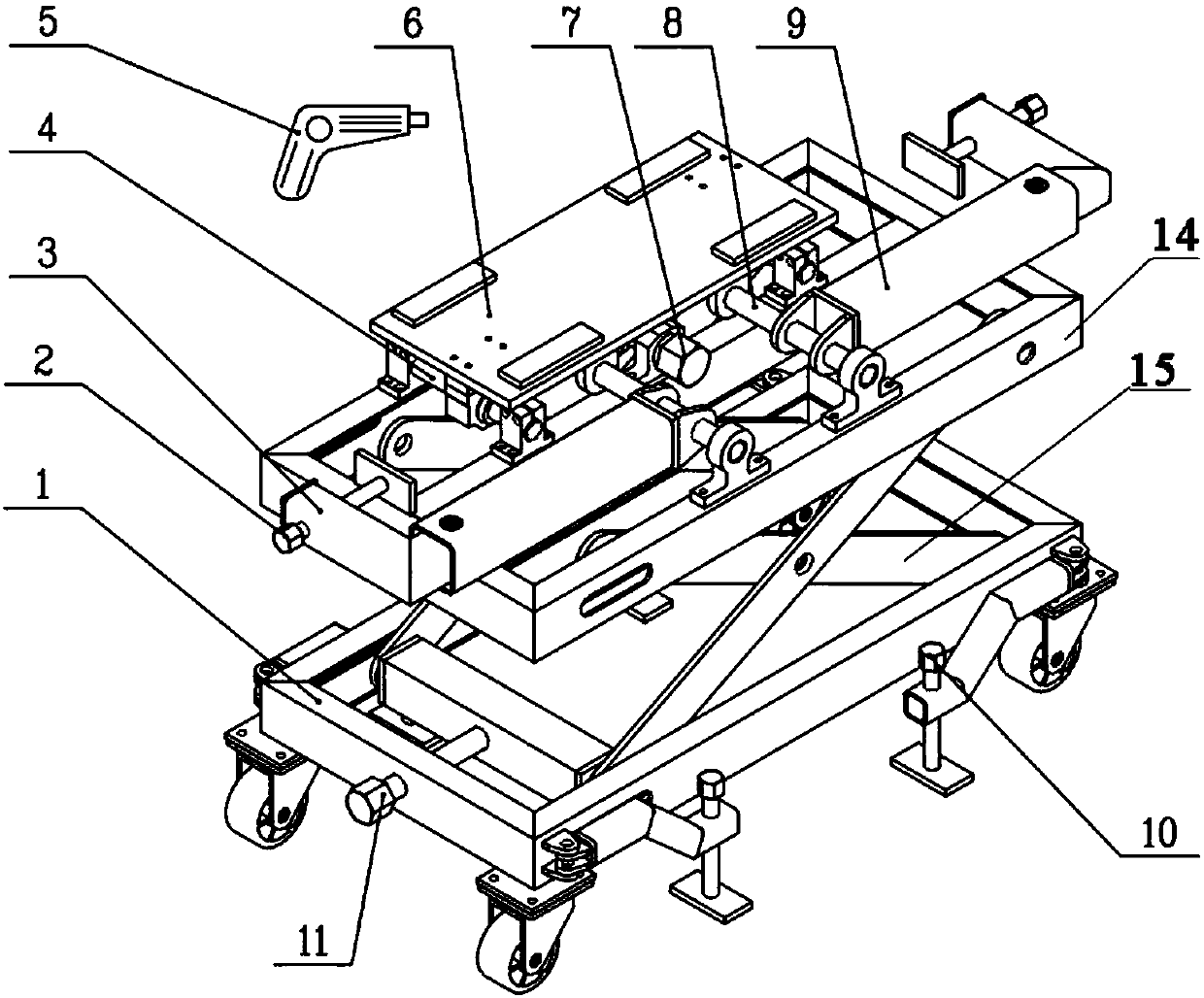

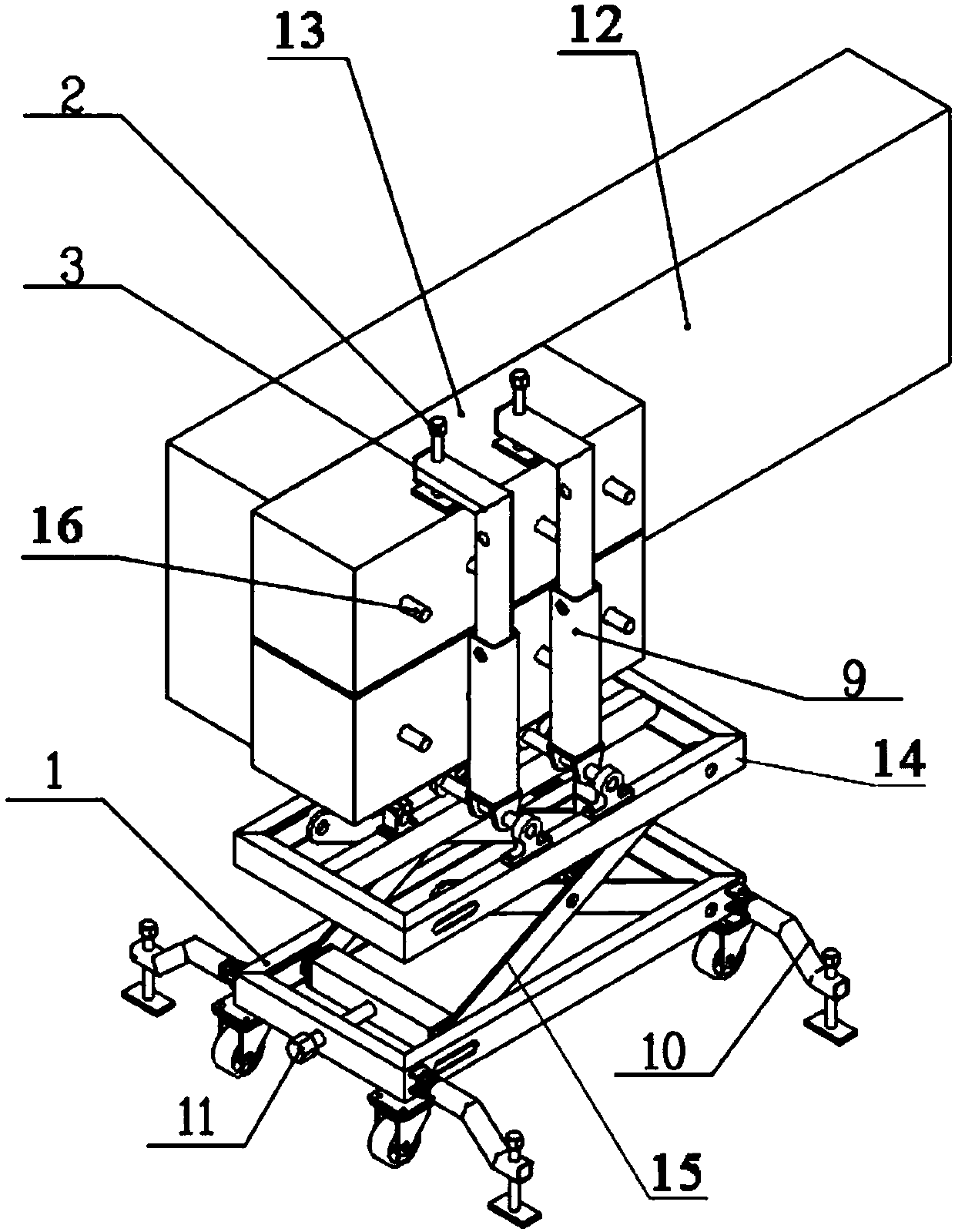

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

[0017] see Figure 1-Figure 3 As can be seen from the figure, the device of the present invention comprises a lifting trolley 1 of a rectangular frame structure, and the lifting trolley 1 is provided with a lifting frame 15, and the supporting platform 14 of a rectangular frame structure is supported at the top of the lifting frame 15 , two hinge shafts 8 are fixed side by side in the middle of the support platform 14, and a square tube 9 is hingedly connected to each hinge shaft 8, and the square tube 9 can rotate around the hinge shaft 8; A telescopic rod 3 is provided at the top, and the clamp 2 is connected to the telescopic rod 3; a mobile platform 6 is also provided on the support platform 14, and a guide device 4 is provided at the bottom of the mobile platform 6.

[0018] Wherein, the hinge sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com