Multi-pipe connected inerter device

A technology for connecting inerters and tubes, which is applied in the field of multi-tube connection inerters, which can solve the problems of device stability degradation and achieve the effects of easy installation and arrangement, stable performance, and fast vibration absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

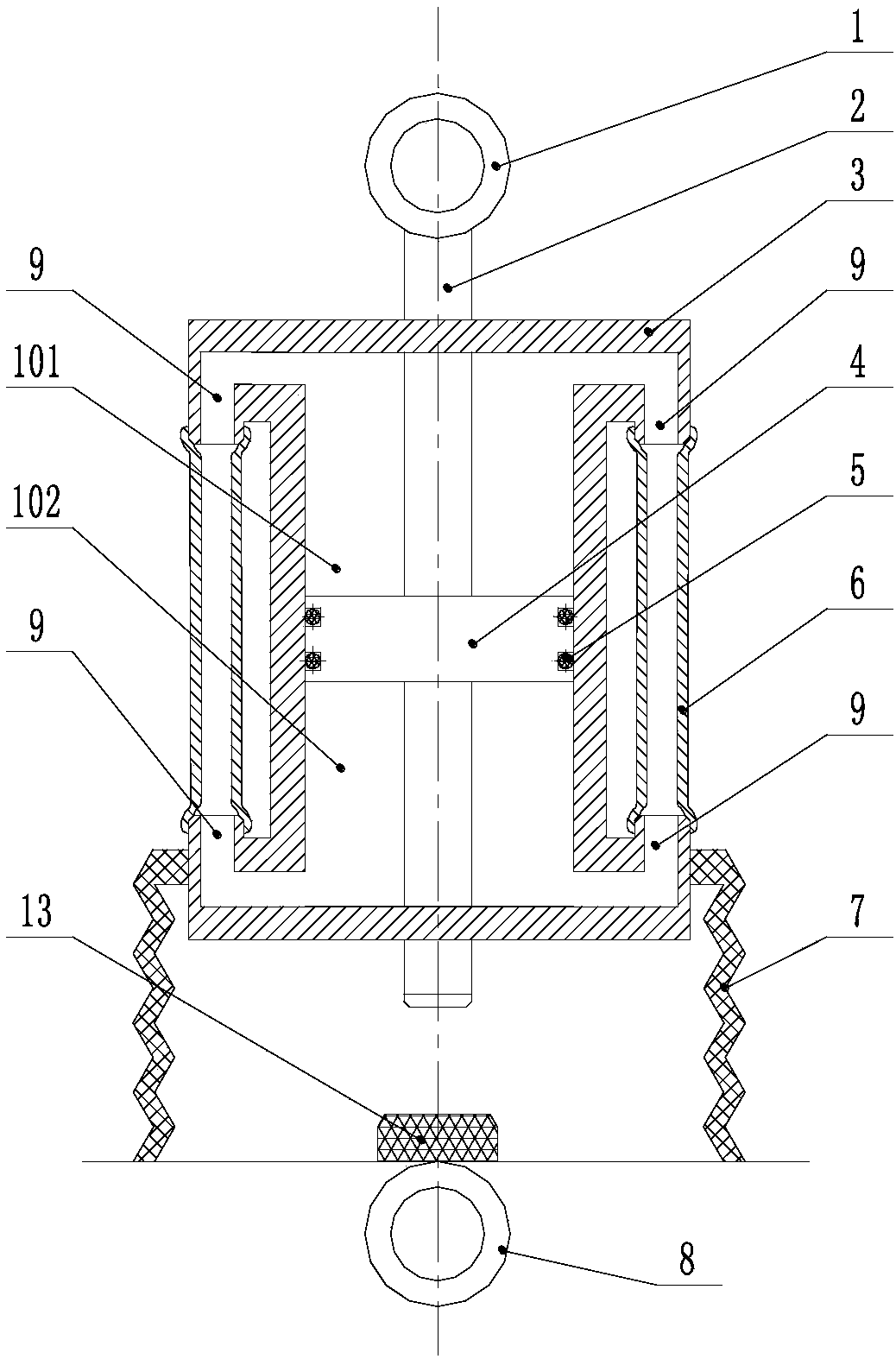

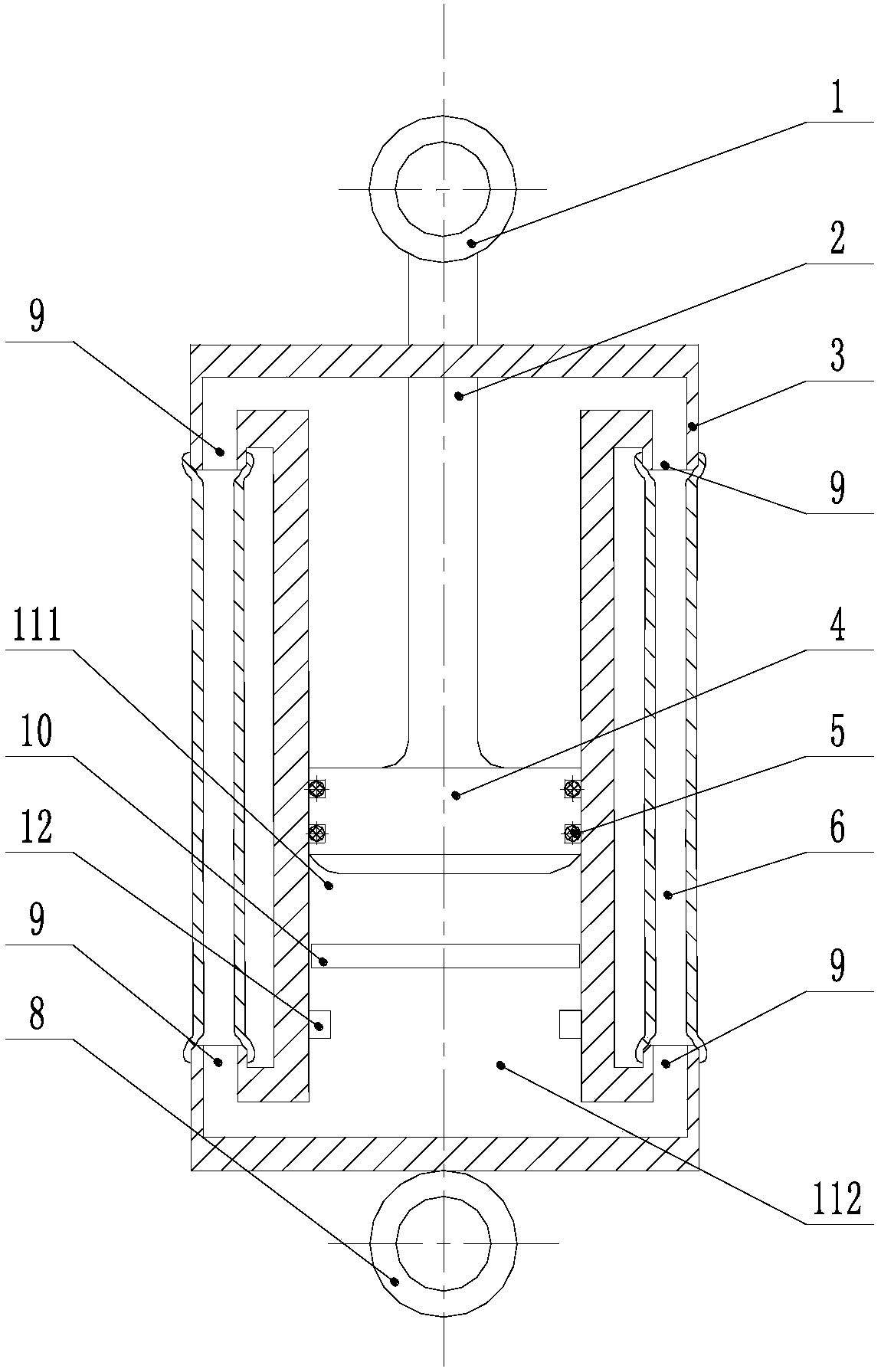

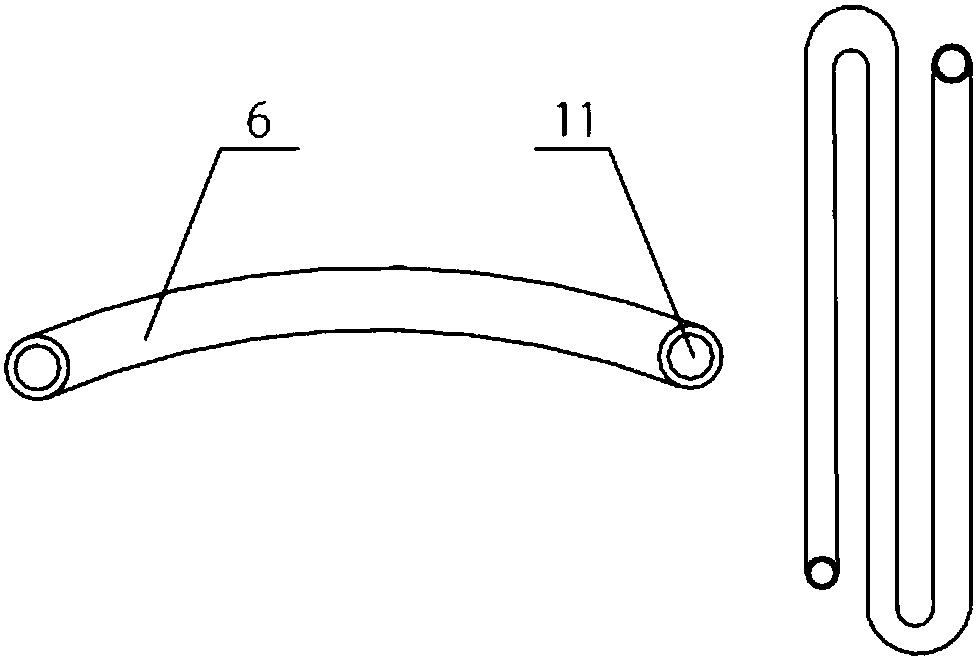

[0024] Such as figure 1 As shown, a multi-pipe connection inerter device includes an upper lifting lug 1, a piston rod 2, a hydraulic cylinder barrel 3, a piston 4, a sealing ring 5, a connecting pipe 6, a hydraulic cylinder outer sleeve 7, a lower lifting lug 8, a The hole 9, the limit block 13, the upper chamber 101 and the lower chamber 102. The hydraulic cylinder 3 is provided with a piston rod 2, and the piston rod 2 protrudes from the bottom of the hydraulic cylinder 3 to the inside of the hydraulic cylinder outer casing 7, the middle part of the piston rod 2 is fixedly connected to the piston 4, and the piston 4 is provided with a sealing ring 5, The piston 4 divides the hydraulic cylinder 3 into an upper chamber 101 and a lower chamber 102; the cylinder walls of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com