A high-load truss-type high-flexibility mechanism

A truss-type, highly flexible technology, which is applied in the direction of manipulators, mechanical equipment, program-controlled manipulators, etc., can solve the problems that flexible mechanisms are not suitable for complex and flexible deformation, and the deformation range is limited, so as to achieve unlimited actuation range and large deformation range , the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

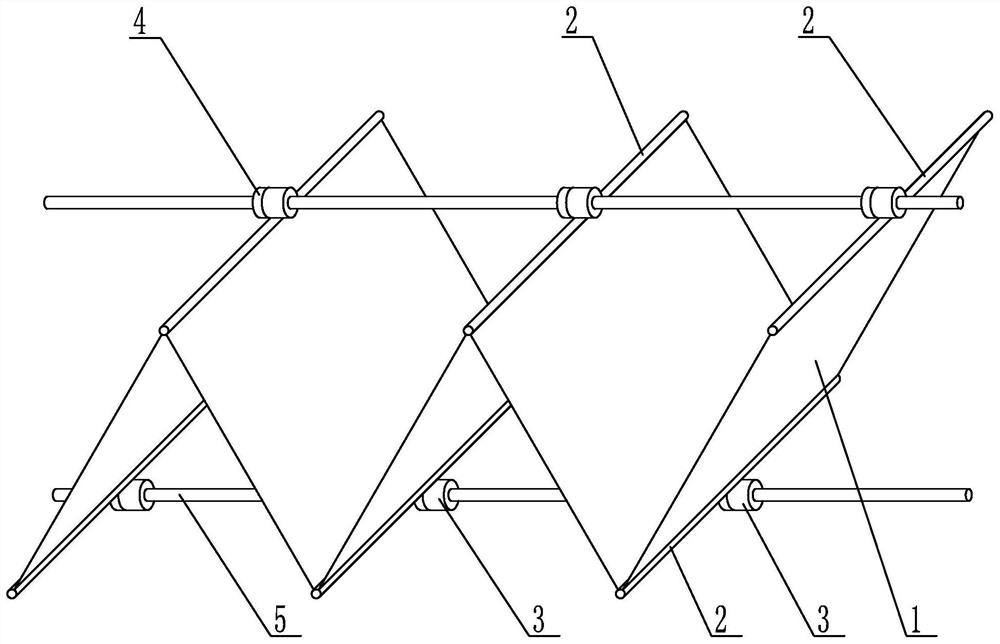

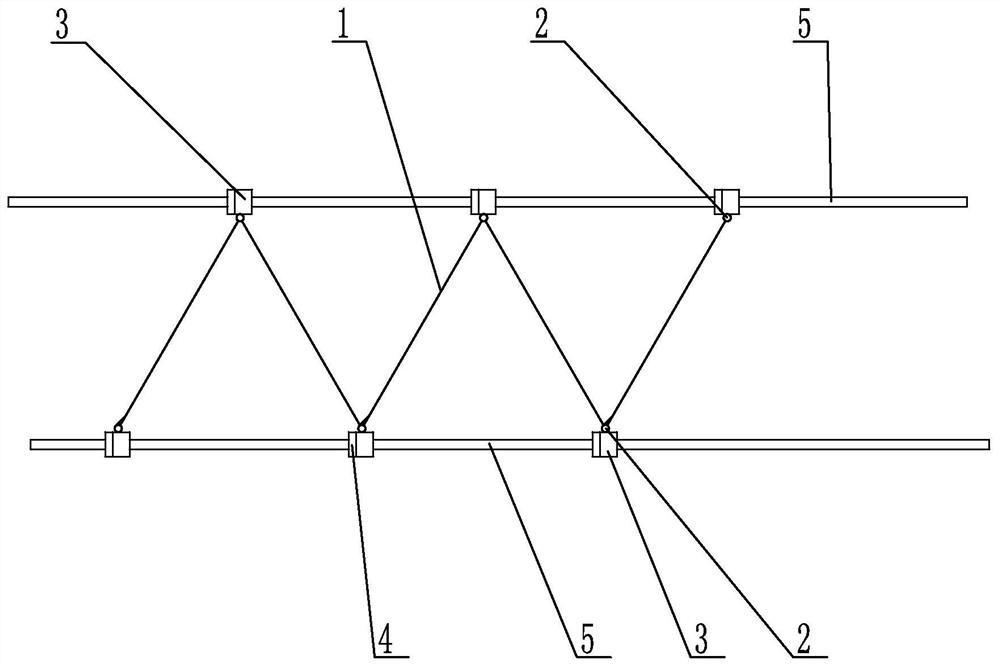

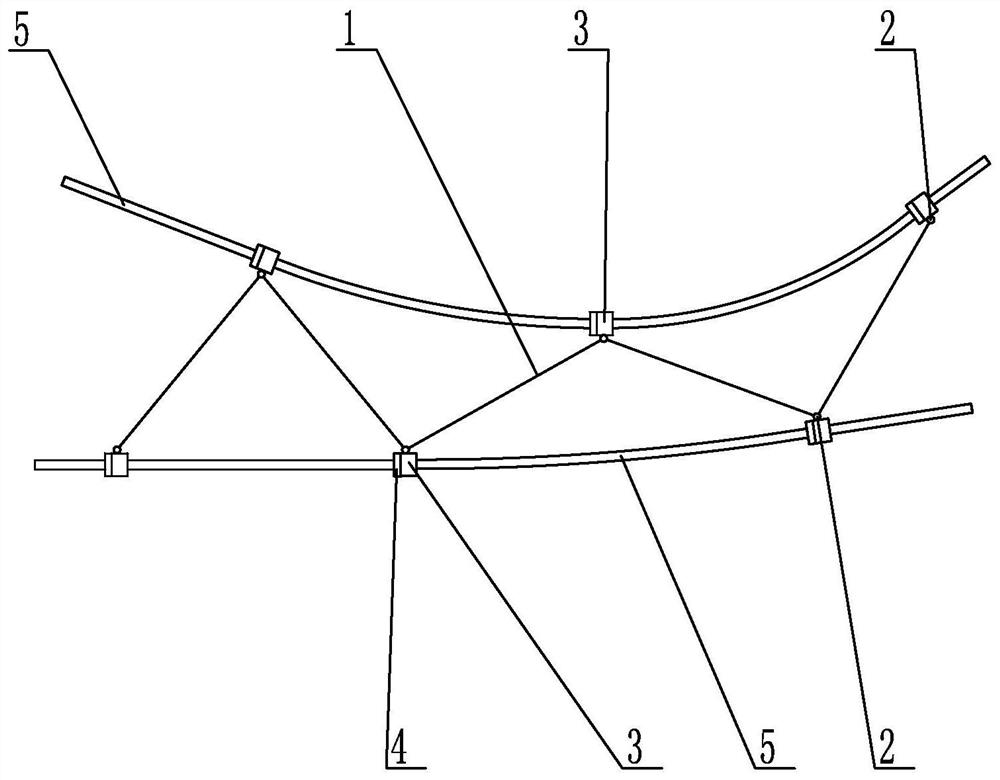

[0016] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, a high-load truss-type high-flexibility mechanism described in this embodiment includes multiple truss units 1, multiple hinges 2, multiple sliders 3, multiple actuators 4 and multiple flexible rods 5, A plurality of truss units 1 are sequentially connected as a whole through hinges 2. A slider 3 is fixedly connected to the hinge 2. The actuating mechanism 4 is fixedly connected to the slider 3. The slider 3 is set on the flexible rod 5. The slider 3 is in the Driven by the actuating mechanism 4, it moves along the flexible rod 5.

[0017] The truss unit 1 is connected end to end by the hinge 2 as a whole, the slider 3 is fixedly connected to the hinge 2, the actuating mechanism 4 is fixedly connected to the slider 3, the flexible rod 5 passes through the slider 3, and the slider 3 is connected to the actuator 4. Driven to move along the flexible rod 5.

[0018] The plurality of ...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 1 to Figure 5 This embodiment will be described. The actuating mechanism 4 in this embodiment is an ultrasonic linear motor. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 1 to Figure 5 To describe this embodiment, the hinge 2 in this embodiment is a flexible hinge made of continuous elastic material. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com