Rotation mechanical fault feature extraction method and device

A technology of fault characteristics and rotating machinery, applied in the field of mechanical vibration, can solve the problems of non-uniform decomposition scale, low efficiency and long running time of one-dimensional signal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

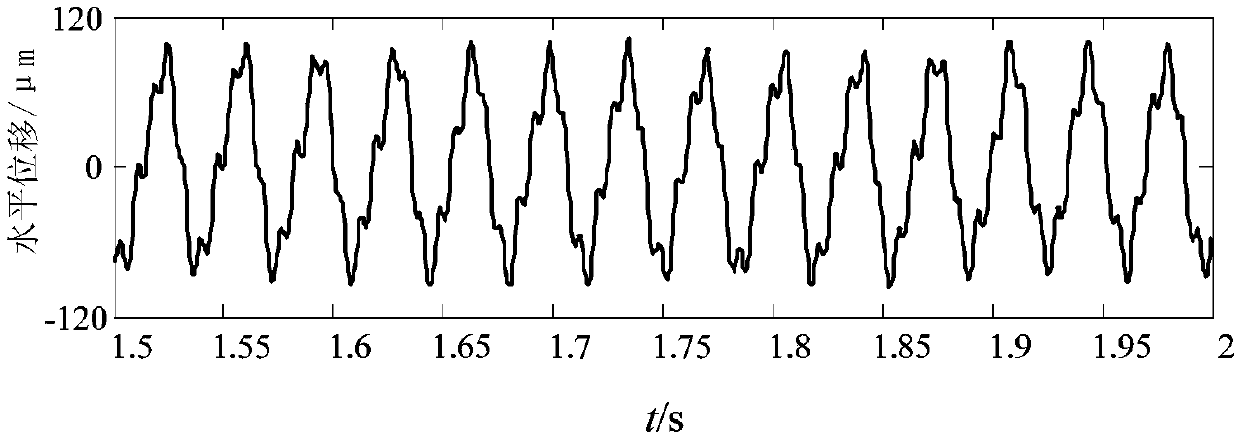

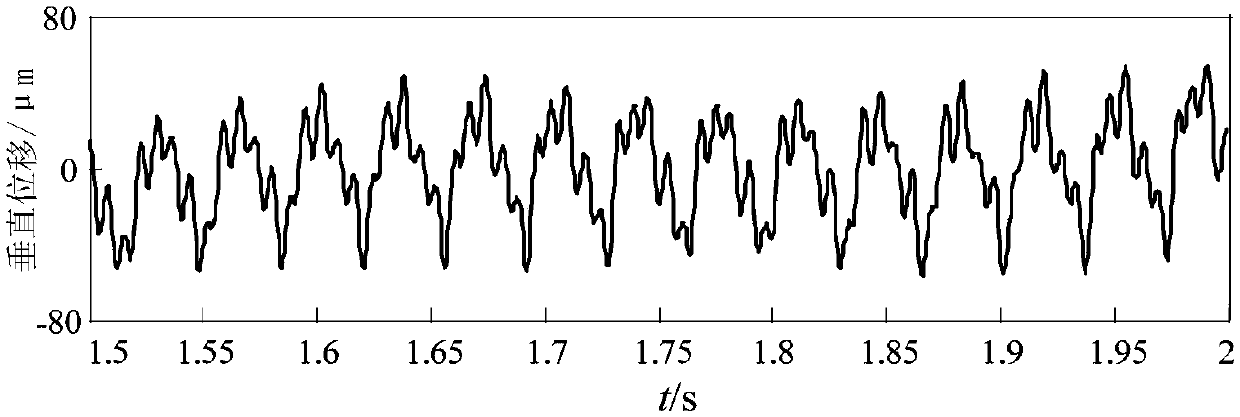

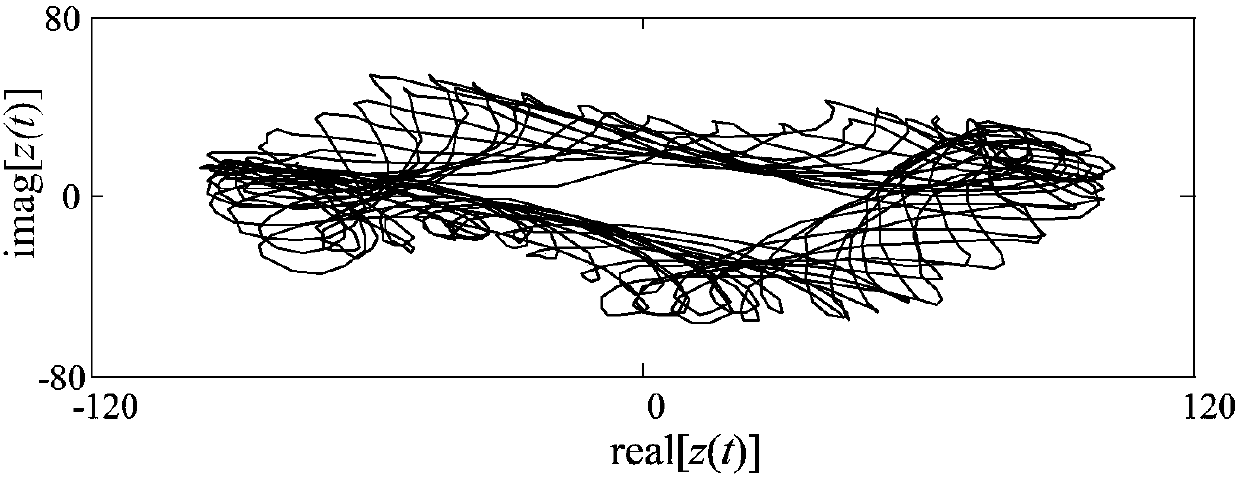

[0083] Aiming at the deficiencies of the prior art, the present invention proposes a binary feature scale decomposition method—complex local feature scale decomposition (CLCD), which is combined with the full vector spectrum technology to directly process the dual-channel signal to ensure It ensures that the signals of each channel have the same decomposition scale, which is convenient for information fusion. Because CLCD uses bilinear transformation, the method has strong adaptability, comprehensive fault feature extraction, fast speed and high efficiency, and has good technical effect. The specific implementation process of the method is as follows.

[0084] The first step is to propose a binary feature scale decomposition method - Complex Local Feature Scale Decomposition (CLCD). The specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com