Ball mill load parameter soft measuring method

A load parameter and ball mill technology, applied in the field of soft sensor, can solve the problems of soft sensor model performance deterioration and achieve important practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

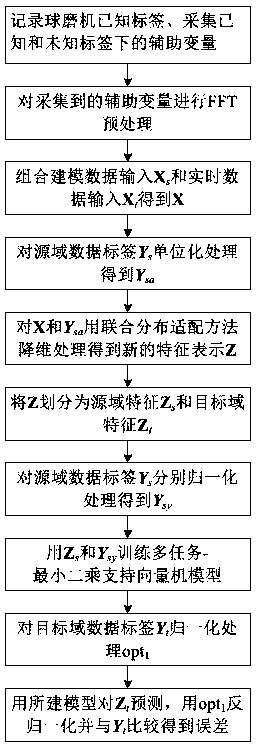

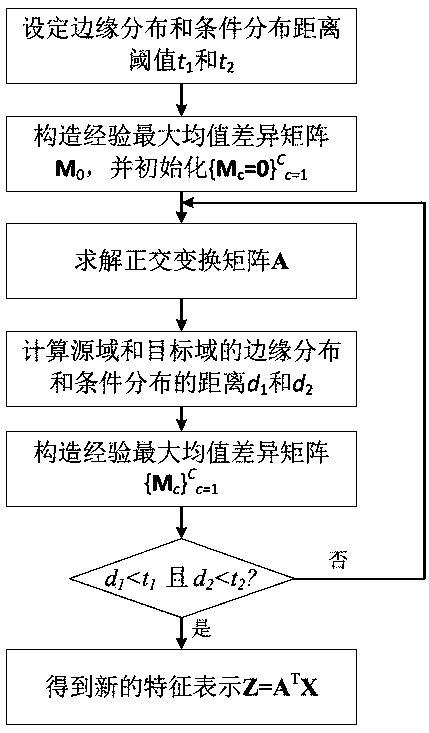

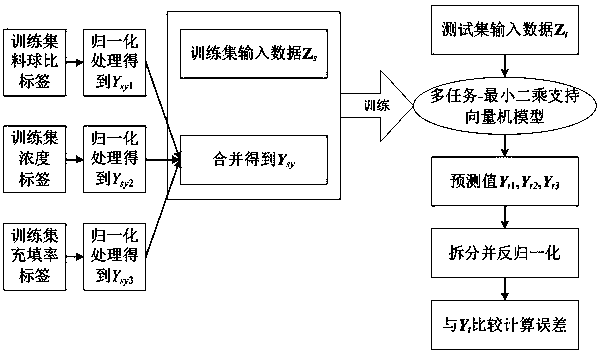

[0035] Such as figure 1 Shown, a kind of ball mill load parameter soft measurement method of the present invention comprises the following steps:

[0036] S100. Define the load parameters of the ball mill as labels, record known labels, collect auxiliary variables under known label working conditions, auxiliary variables under unknown label working conditions, and form known labels and auxiliary variables under known label working conditions The field of modeling data is used as the source domain, and the field of real-time data formed by unknown labels and auxiliary variables under unknown label working conditions is used as the target domain; auxiliary variables are selected from the vibration signal on the wall of the ball mill or the bearing, and the vibration signal around the roller of the ball mill .

[0037] S200. Preprocessing the auxiliary variables through FFT to obtain source domain data and target domain data where n s Indicates the number of samples in the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com