Capsule polishing machine capable of conveniently removing dust

A technology of polishing machine and capsule, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. It can solve the problems of affecting the effect of polishing brushes and reducing the normal operation of the machine, so as to ensure cleanliness and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

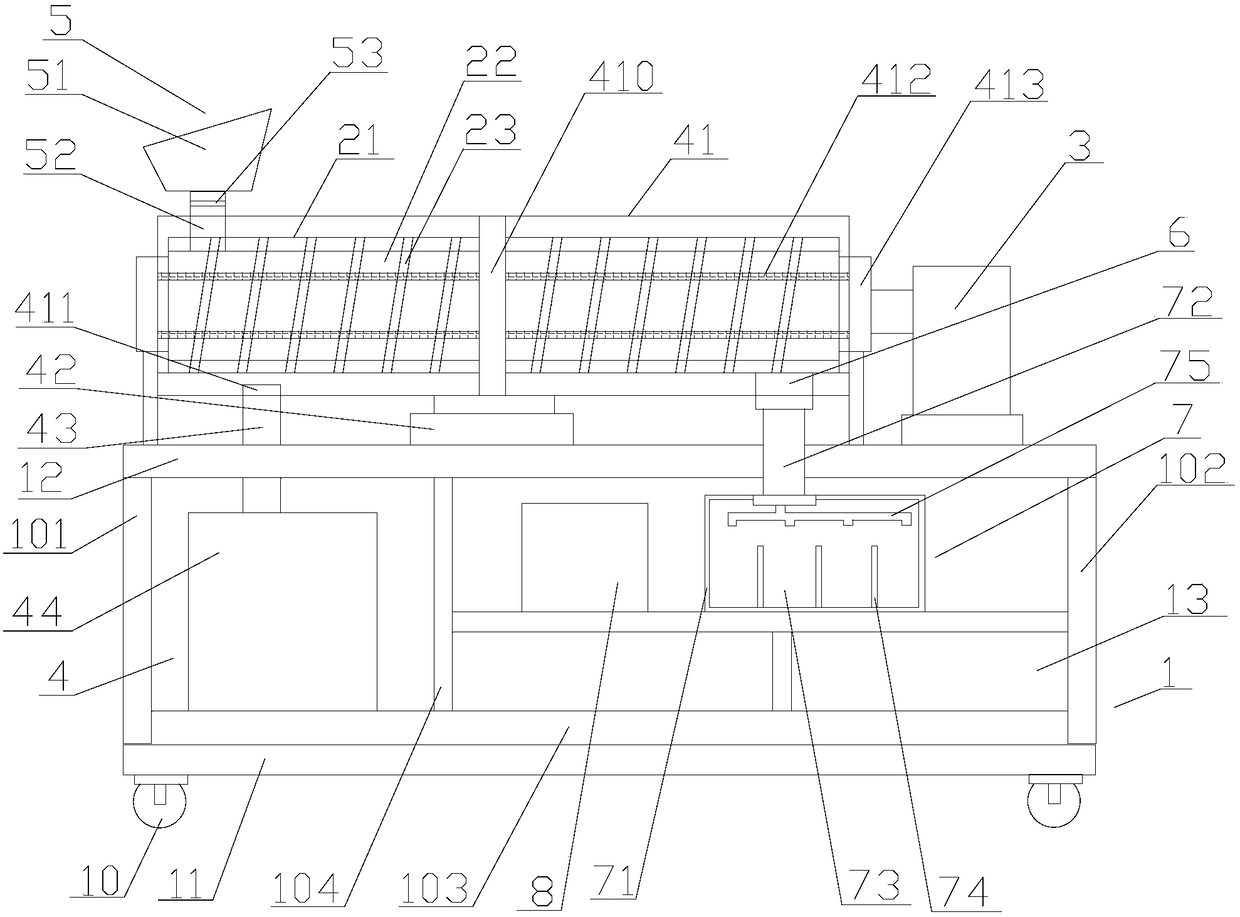

[0016] refer to figure 1 , a kind of capsule polishing machine that is convenient for dust removal of the present invention, comprises frame 1, polishing cylinder 2, suction fan 3, dust removal device 4, feed hopper 5, discharge port 6, material storage box 7, motor 8, described machine Frame 1 comprises base 11, table top 12 and frame body 13, and described base 11 is provided with frame body 13, and the top of described frame body 13 is provided with table top 12, and polishing tube 2 is installed on the described table top 12, One end of the polishing cylinder 2 is provided with a suction fan 3, the bottom of the polishing cylinder 2 is connected with the dust removal device 4, and the polishing cylinder 2 is provided with a feed hopper 5 and a discharge port 6, and the discharge port 6 Connected with the material storage box 7, the material storage box 7, the motor 8 and the material storage box 7 are arranged on the mounting frame 13, and the dust removal device 4 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com