Edge covering machine and automatic edge covering system with same

An edge-wrapping machine and edge-wrapping technology, applied in transportation and packaging, lamination devices, lamination, etc., can solve the problems of time-consuming, labor-intensive, and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0035] Please refer to figure 1 with Figure 5 , the automatic hemming system of the present invention includes a hemming machine 100, a honeycomb board feeder 200, a film conveyor 300 and a fabric feeder (not marked). The honeycomb plate feeding machine 200 , the fabric feeding machine and the film conveyor 300 are arranged on three adjacent sides of the edge binding machine 100 . The material feeder uses needle insertion to transport the material to the hemming machine 100; the material can be leather or cloth.

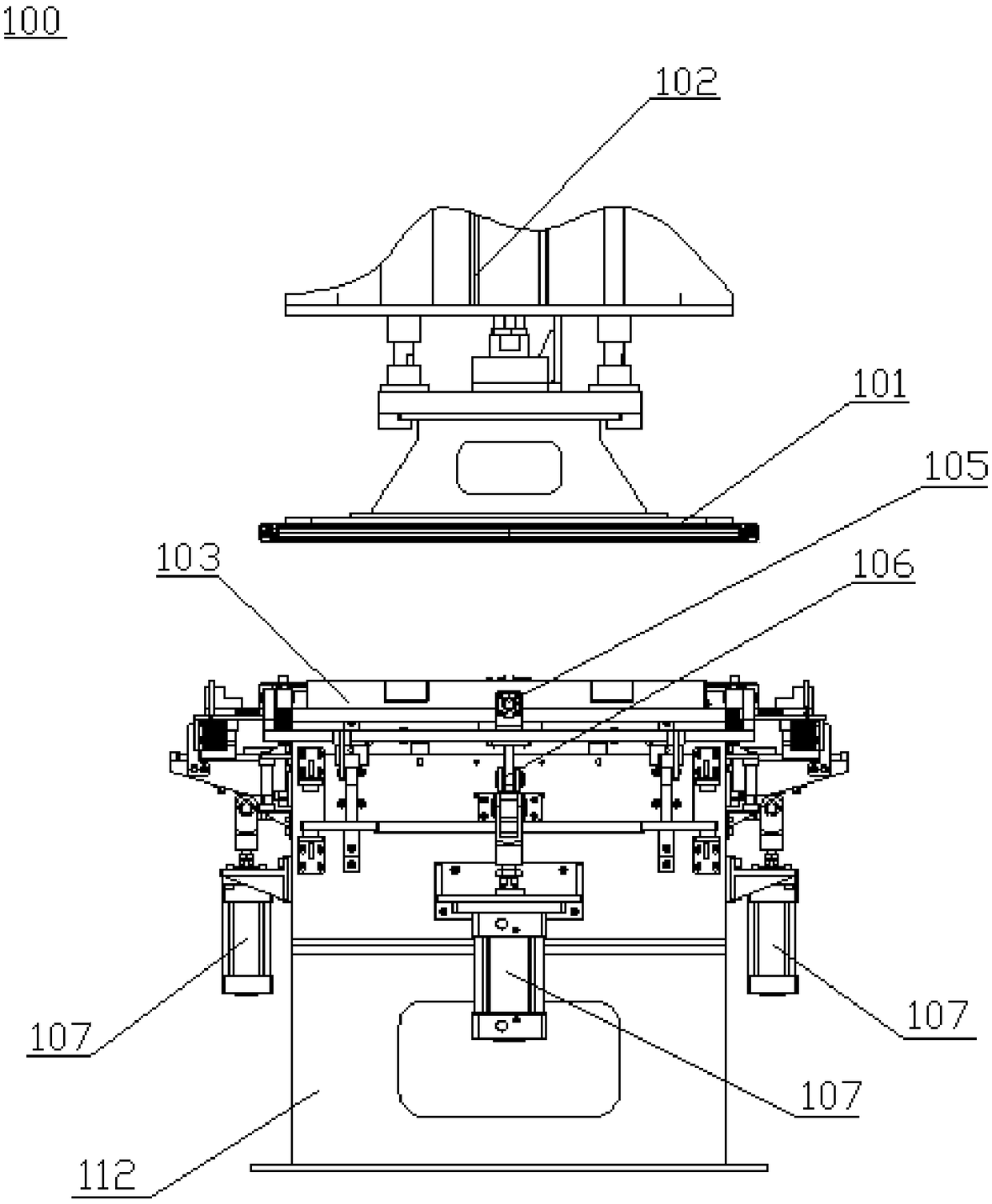

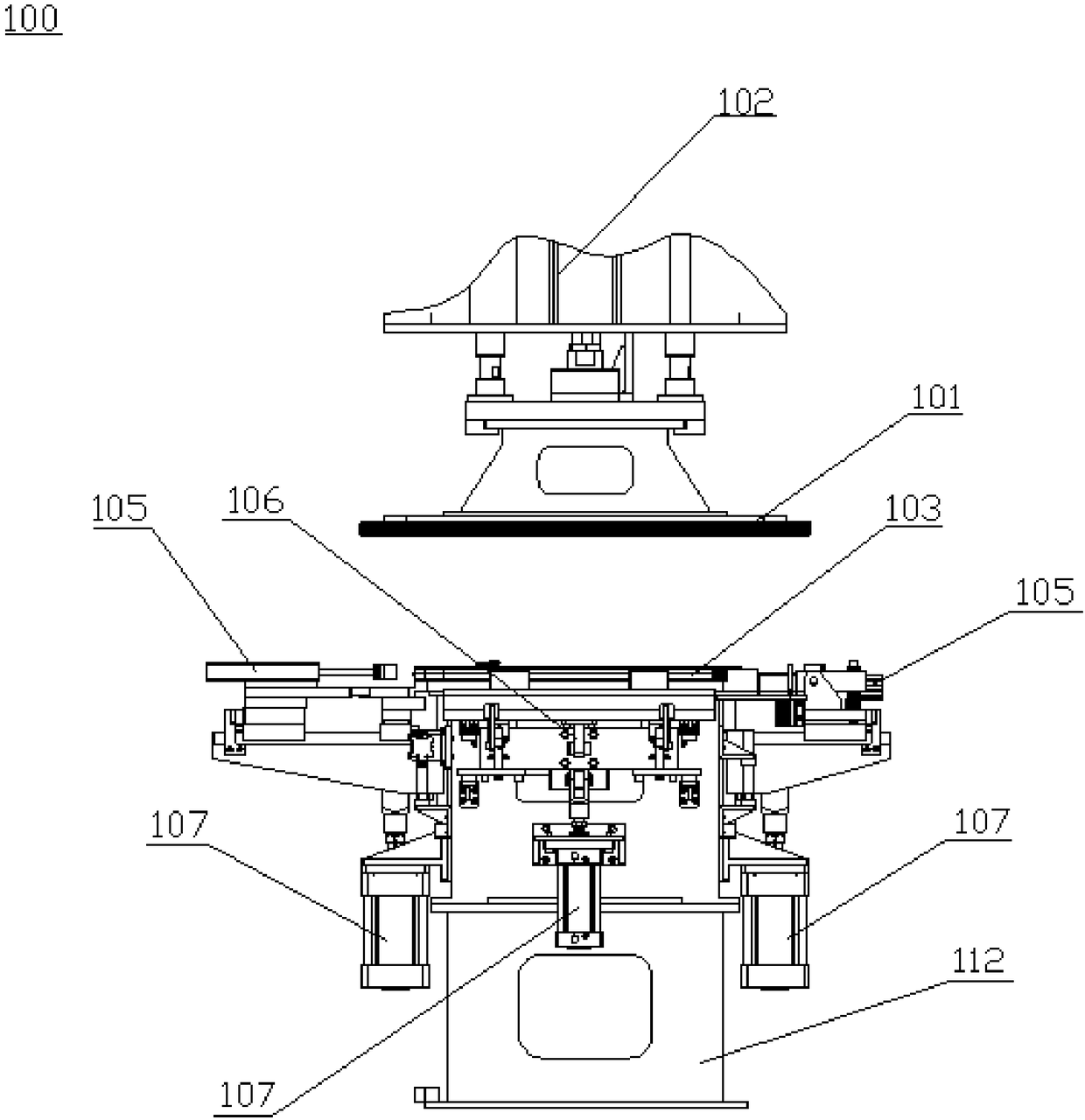

[0036] Please refer to Figure 2 to Figure 4 , the hemming machine 100 includes a hemming base 112, an upper mold 101 and a lower mold 103; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com