Method for debugging optical axis parallelism of multiple optical devices

An optical device, optical axis-parallel technology, applied in the parts and instruments of the instrument, can solve the problems of investing a lot of money, expensive large-diameter collimator, increasing production cost, etc., to improve efficiency, reasonable design, and economical cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0018] A method for adjusting the parallelism of optical axes of multiple optical devices, comprising the following steps:

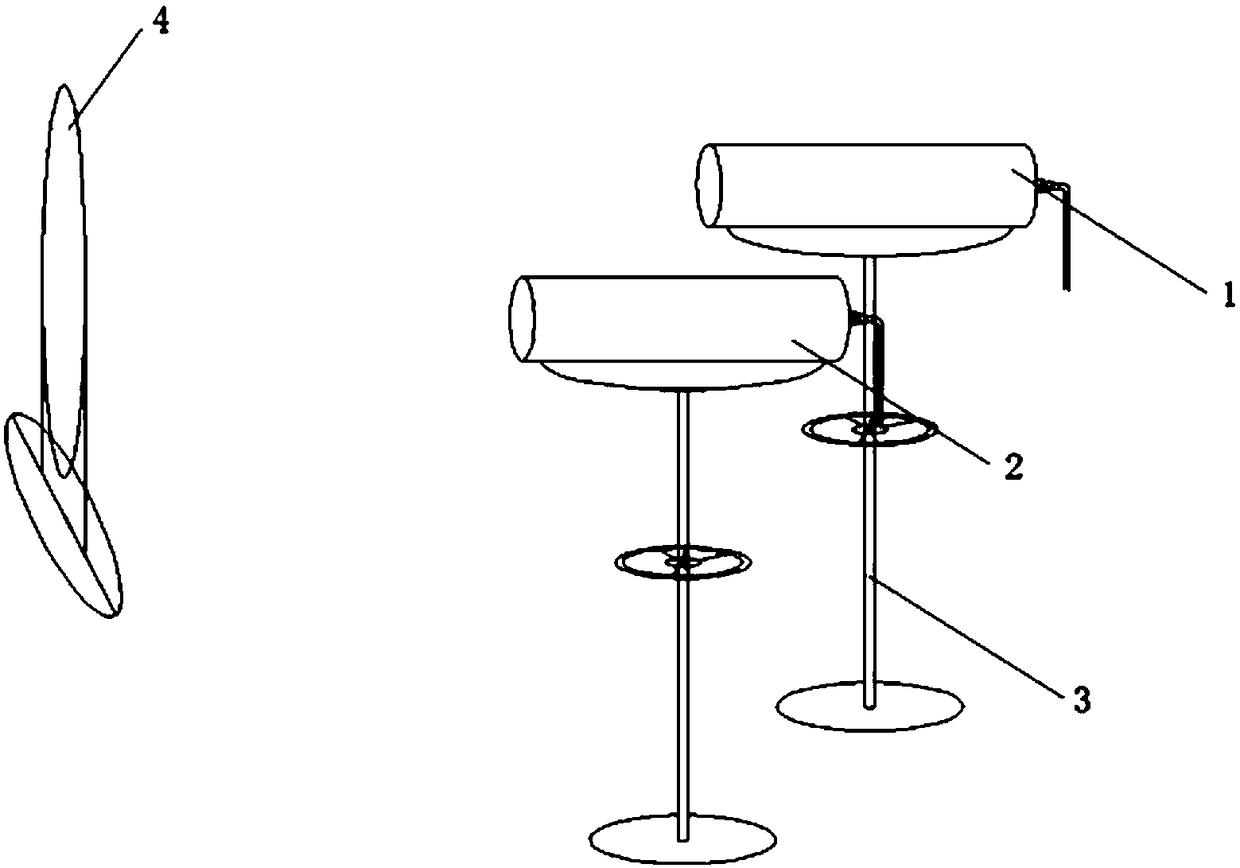

[0019] (1) Place the plane mirror 4 on the large flat plate of the static base, and place two liftable collimator brackets 3 at a distance of 2-4m from the plane mirror, and install a collimator on each collimator bracket. According to the installation positions of the TV camera and the laser range finder, adjust the relative positions of the two collimators to be consistent with the relative positions of the TV camera and the laser range finder to be adjusted.

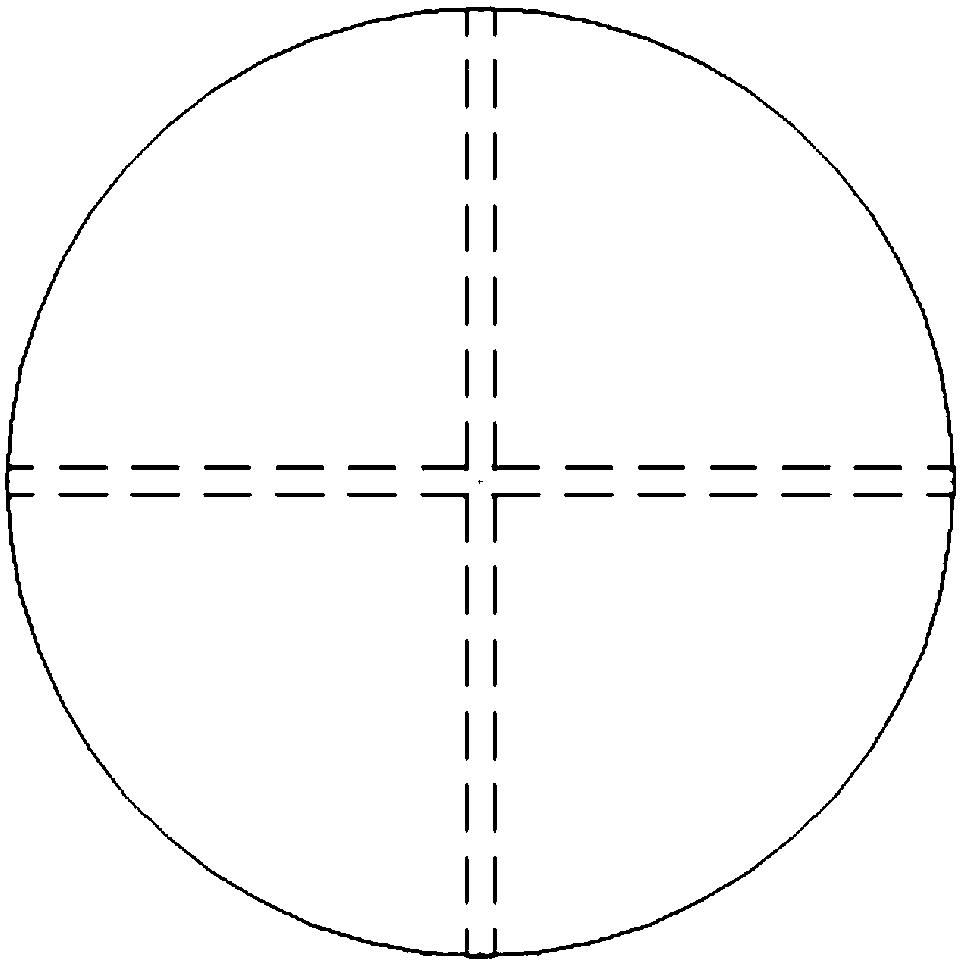

[0020] ⑵. Turn on the power of the No. 1 collimator, observe the cursor image returned by the plane mirror from the No. 1 collim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com