Method for evaluating life of plastic pipe

A technology for plastic pipes and evaluation methods, applied in the direction of analyzing materials, using stable tension/pressure to test material strength, measuring devices, etc., can solve the inaccurate evaluation results, hinder the development speed of special resins for plastic pipes, and be difficult to observe Sample failure and other problems, to achieve the effect of reducing the evaluation cycle, increasing the development speed, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

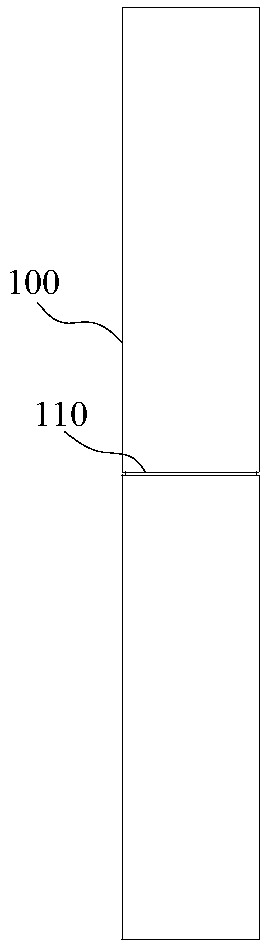

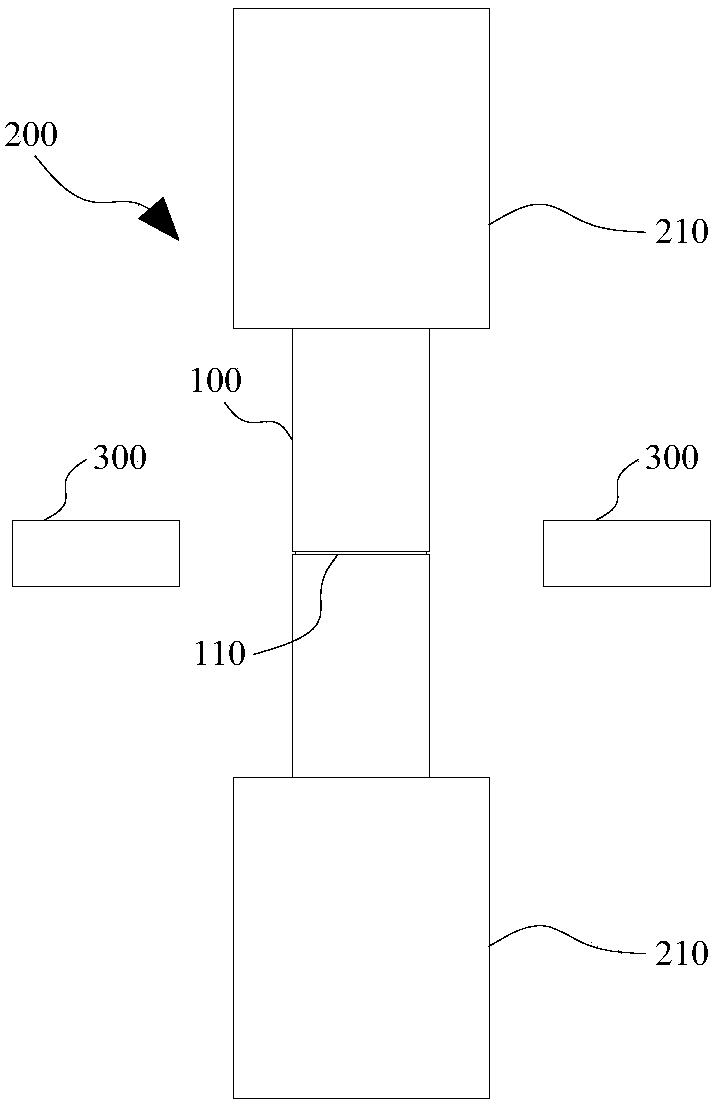

[0040] This embodiment provides a method for evaluating the life of a plastic pipe, which is based on figure 1 The sample 100 implementation shown in Please refer to figure 1 , the sample 100 is cylindrical and has an annular prefabricated notch 110 on its peripheral surface. It should be noted that the diameter of the sample 100 can be selected between 13mm-15mm, and the length of the sample 100 can be selected between 70mm-110mm. Further, the diameter of the sample 100 can be controlled between 13.5mm-14.5mm, and the length of the sample 100 can be controlled between 90mm-100mm. In this way, it is possible to avoid the problem that the test result cannot be accurately displayed due to the too small size of the sample 100 , and the problem that the evaluation cycle is too long due to the too large size of the sample 100 can be avoided. In this embodiment, the diameter of the sample 100 is 14 mm, and the length of the sample 100 is 95 mm. The prefabricated notch 110 is set...

Embodiment 2

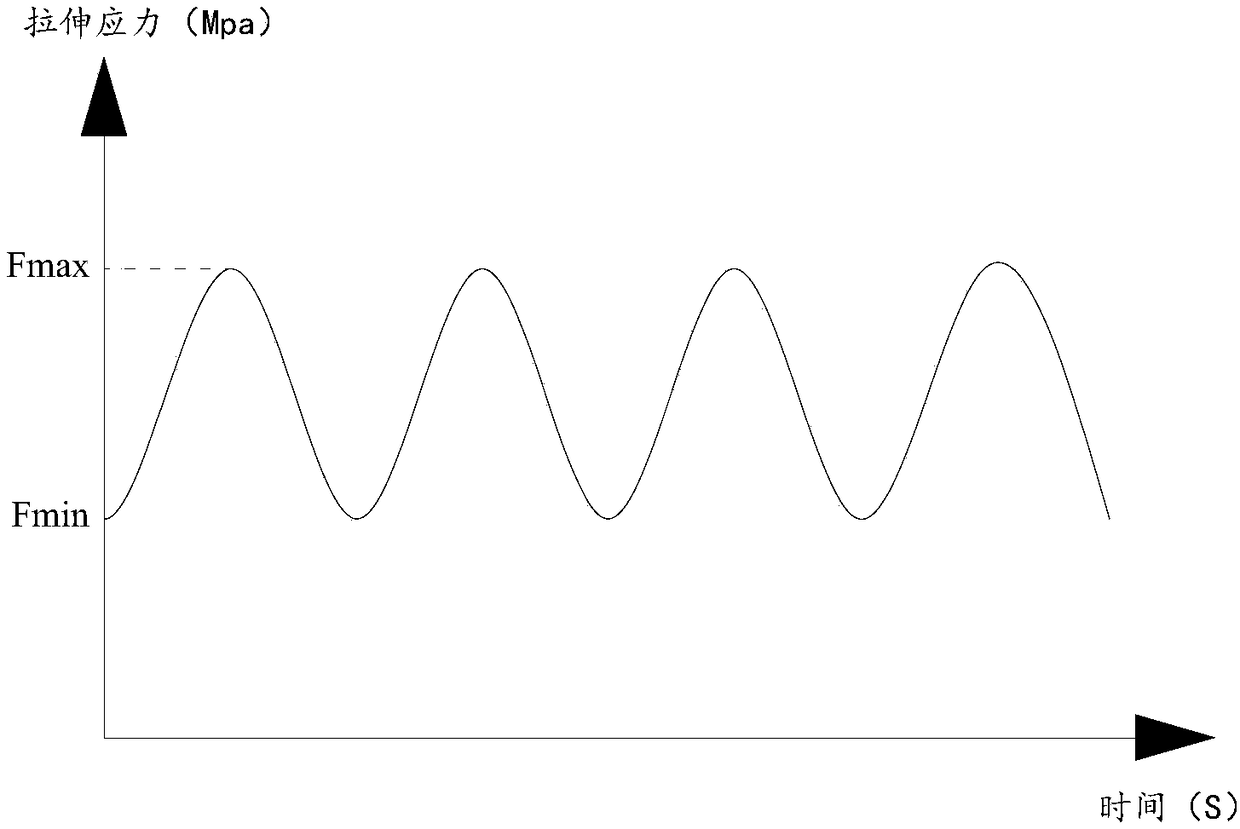

[0074] In this example, the plastic pipe life evaluation method provided in Example 1 is used to test four different materials, PE100-1, PE100-2, PE100RC-3 and PE100RC-4, and the expressions T and △ The lines for the σ relationship are plotted in the same log-log plot. Figure 5 It is the log-log coordinate diagram in this embodiment. pass Figure 5 , the stretching time T of the above four materials can be compared under the same stress range Δσ. Under the same stress range △σ, the longer the stretching time T of the material, the longer the service life of the plastic pipe made of it. In this way, the service life of plastic pipes made of different materials can be compared and evaluated, so as to provide a reference for the research and development of special resins for plastic pipes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com