Differential circuits, capacitance detection circuits, touch detection devices, and terminal equipment

A differential circuit and capacitance detection technology, applied in the field of electronics, can solve the problems of inability to integrate cancel capacitors, high cost of cancel capacitors, and low sensitivity, so as to optimize self-capacitance detection equipment, overcome the influence of touch sensitivity, and improve touch sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solutions in the embodiments of the present application will be described below with reference to the accompanying drawings.

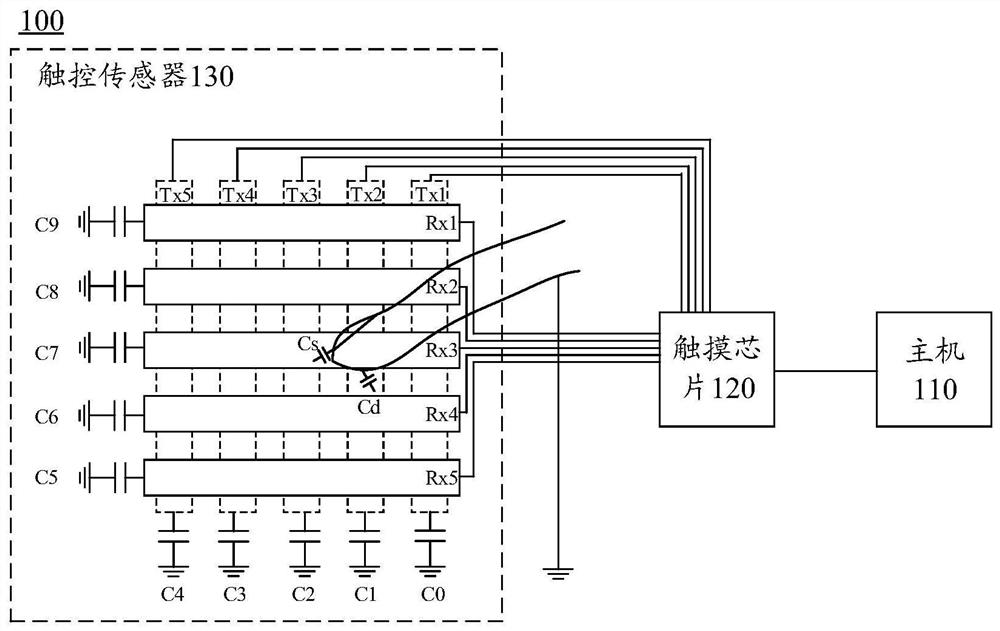

[0066] For ease of understanding, the following combination figure 1 A schematic diagram describing a possible application scenario of the differential circuit in the embodiment of the present application.

[0067] figure 1 A capacitive touch system 100 is shown, and the capacitive touch system 100 includes a host (Host) 110 , a touch integrated circuit (Touch IC) 120 and a touch sensor 130 . Wherein, the touch sensor 130 includes a Tx layer and an Rx layer, the Tx layer includes Tx1 channel, Tx2 channel, Tx3 channel, Tx4 channel and Tx5 channel, and the Rx layer includes Rx1 channel, Rx2 channel, Rx3 channel, Rx4 channel, Rx5 channel. In the Tx layer, the ground capacitances of the Tx1 channel, Tx2 channel, Tx3 channel, Tx4 channel, and Tx5 channel are C0, C1, C2, C3, and C4 respectively; in the Rx layer, the Rx1 channel, Rx2 ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com