Backlight module lens and backlight module lens comprising backlight module lens

A technology of backlight module and lens, applied in the field of backlight, to achieve the effect of uniform distribution of light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

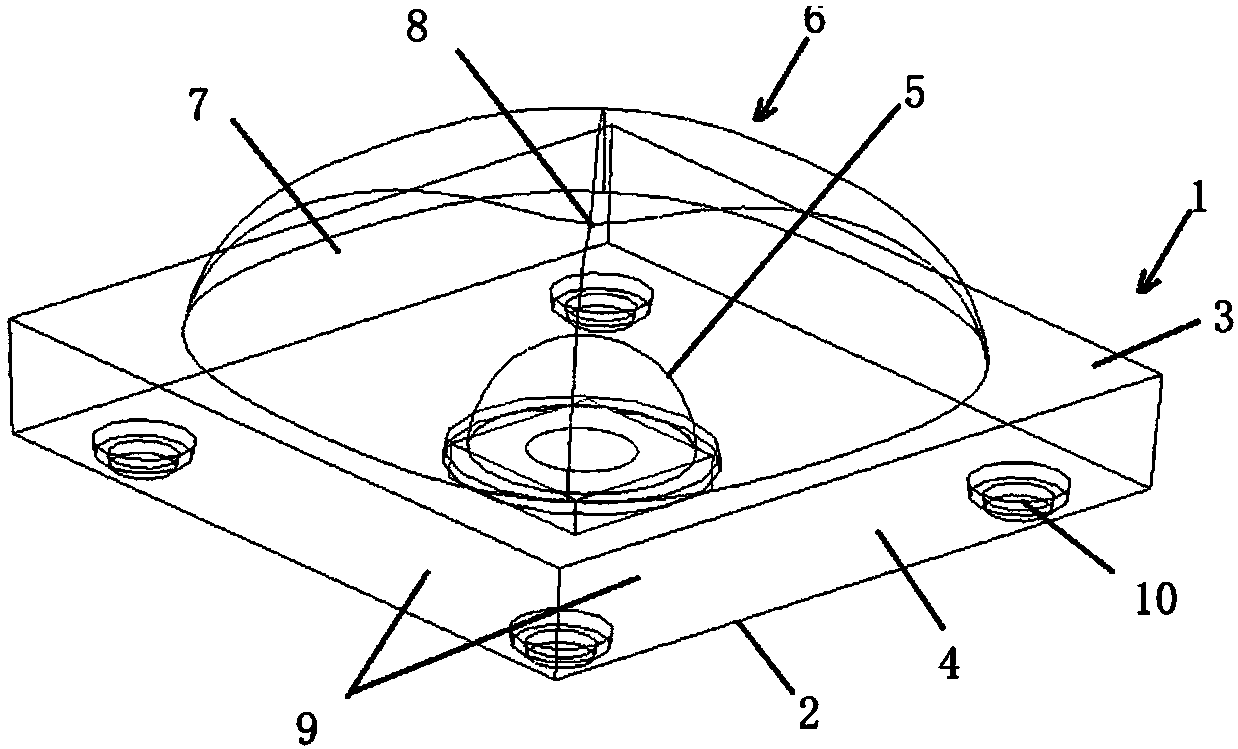

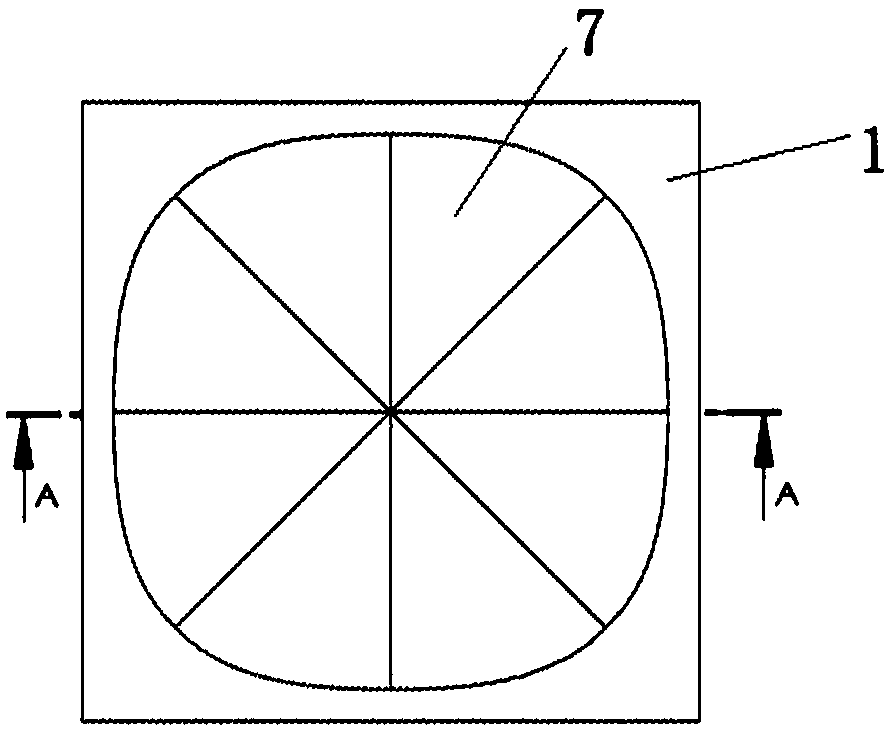

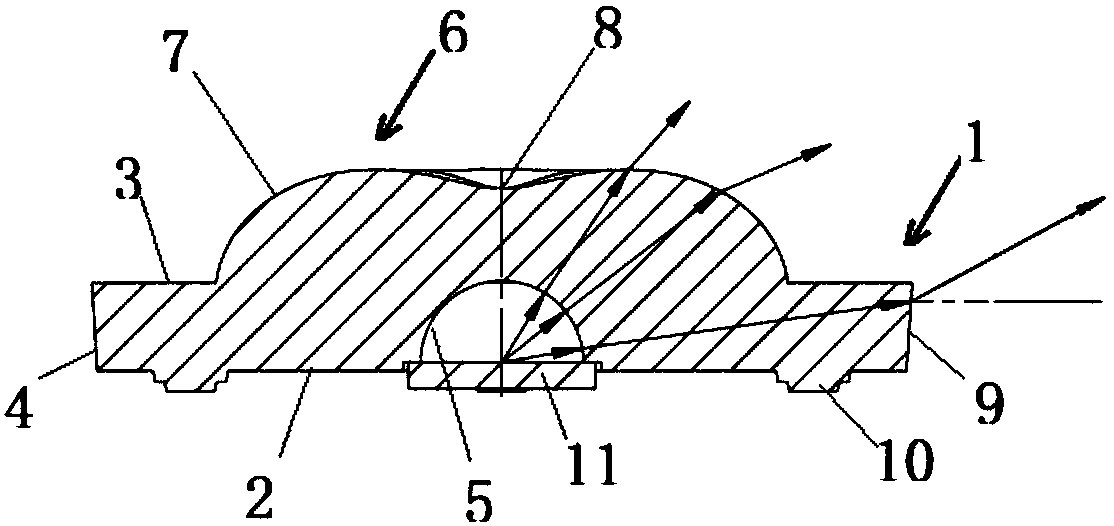

[0031] see attached figure 1 to attach Figure 4 As shown, the backlight module lens in this embodiment is made of glass or optical resin material. The base 1 has a cubic structure as a whole. The base 1 has a square bottom surface 2, a square top surface 3, and side surfaces 4. The bottom surface 2 is provided with positioning columns 10 for installation and positioning. The center of the bottom surface 1 is depressed upward to form a light incident surface 5.

[0032] The top surface 3 bulges upwards to form the main light-emitting surface 6. The main light-emitting surface 6 includes four free-form surfaces 7 spliced together. The four free-form surfaces 7 have a joint center point 8 and are symmetrical around the joint center point 8. The joint center point 8 Recessed downward toward the light-incident surface 5 and located on the same center line as the center point of the light-incident surface 5, wherein the size of the bottom surface 2 of the substrate 1 is smaller ...

Embodiment 2

[0036] see attached Figure 5 to attach Figure 8 As shown, the backlight module lens in this embodiment is made of glass or optical resin material. The base 1 has a cubic structure as a whole. The base 1 has a square bottom surface 2 with rounded corners, a square top surface 3 with rounded corners, and side surfaces 4. The positioning column 10 is used for installation and positioning, and the center of the bottom surface 1 is recessed upward to form the light incident surface 5 .

[0037] The top surface 3 bulges upwards to form the main light-emitting surface 6. The main light-emitting surface 6 includes four free-form surfaces 7 spliced together. The four free-form surfaces 7 have a joint center point 8 and are symmetrical around the joint center point 8. The joint center point 8 It is recessed downward toward the light incident surface 5 and is located on the same center line as the center point of the light incident surface 5, wherein the size of the bottom surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com