Reflecting film and backlight module

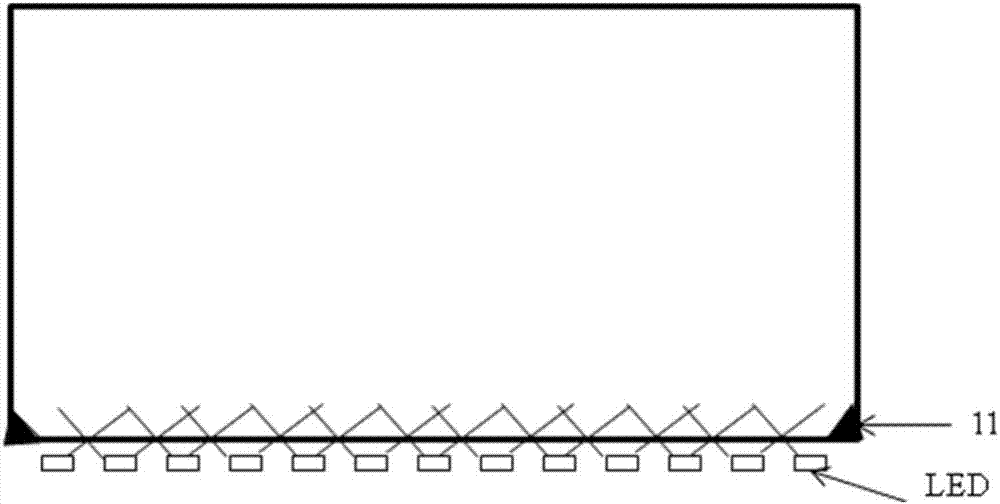

A technology of backlight module and reflective film, applied in optics, nonlinear optics, instruments, etc., can solve the problems of inaccessible light, dark areas in the corners of reflective films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

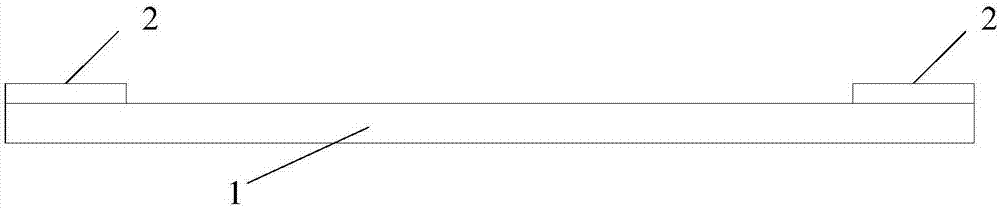

[0021] Reference figure 2 , Which shows a schematic structural diagram of a reflective film according to the first embodiment of the present invention.

[0022] The reflective film 1 is applied to a backlight module, the light source of the backlight module has a dark area formed on the reflective film 1, and the reflective film is coated with a thermoluminescent material 2 at the dark area.

[0023] After a product design is determined, the dark area is also determined, that is, the area of the generated dark area will not change, so the thickness of the thermoluminescent material 2 coating can be adjusted according to the dark area. Preferably, The coating thickness of the thermoluminescent material 2 is 20um-50um, which is not specifically limited in the present invention.

[0024] A thermoluminescent material solution is coated on the dark area of the reflective film, and after a series of treatments, the thermoluminescent material solution is dried to form a thermoluminesce...

Embodiment 2

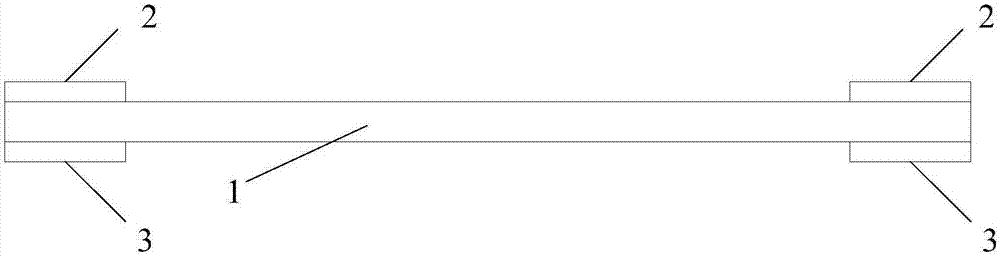

[0028] Reference image 3 , Which shows a schematic structural diagram of a reflective film according to the second embodiment of the present invention.

[0029] The reflective film 1 is applied to a backlight module, the light source of the backlight module has a dark area formed on the reflective film 1, and the reflective film is coated with a thermoluminescent material 2 on the front surface of the dark area. , The backside of the dark area is coated with an endothermic and heat accumulating material 3.

[0030] Because after a product design is determined, the area of the dark area will not change. The thickness of the thermoluminescent material 2 and the endothermic heat gathering material 3 can be adjusted according to the dark area. Preferably, the The coating thickness of the thermoluminescent material 2 and the endothermic heat gathering material 3 is 20um-50um, which is not specifically limited in this application.

[0031] Apply a mixture of thermoluminescent material ...

Embodiment 3

[0042] The invention also discloses a backlight module, including the reflective film described in the first to second embodiments.

[0043] The backlight module has all the advantages of the reflective film in the first to second embodiments described above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com