Sand core assembling device in casting process

A technology for assembling devices and sand cores, which is applied to casting molding equipment, casting molds, and cores, etc., can solve the problems of broken sand cores, waste, time-consuming and labor-intensive connections, and achieve the effects of saving costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

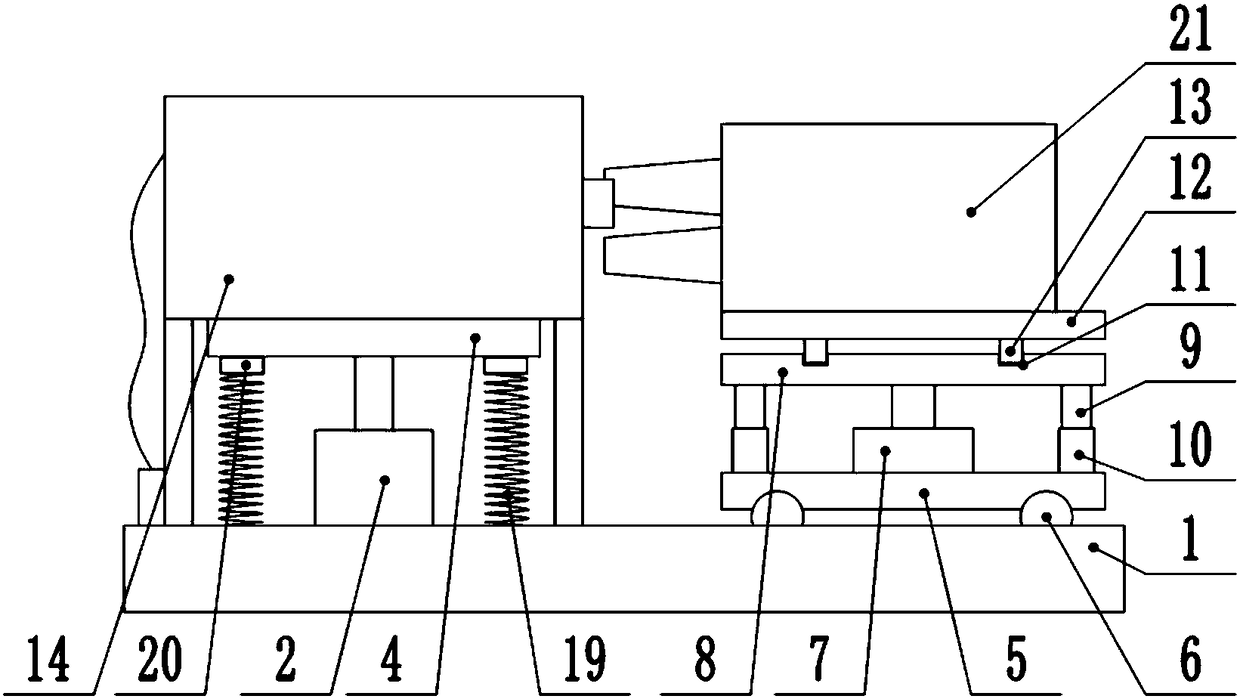

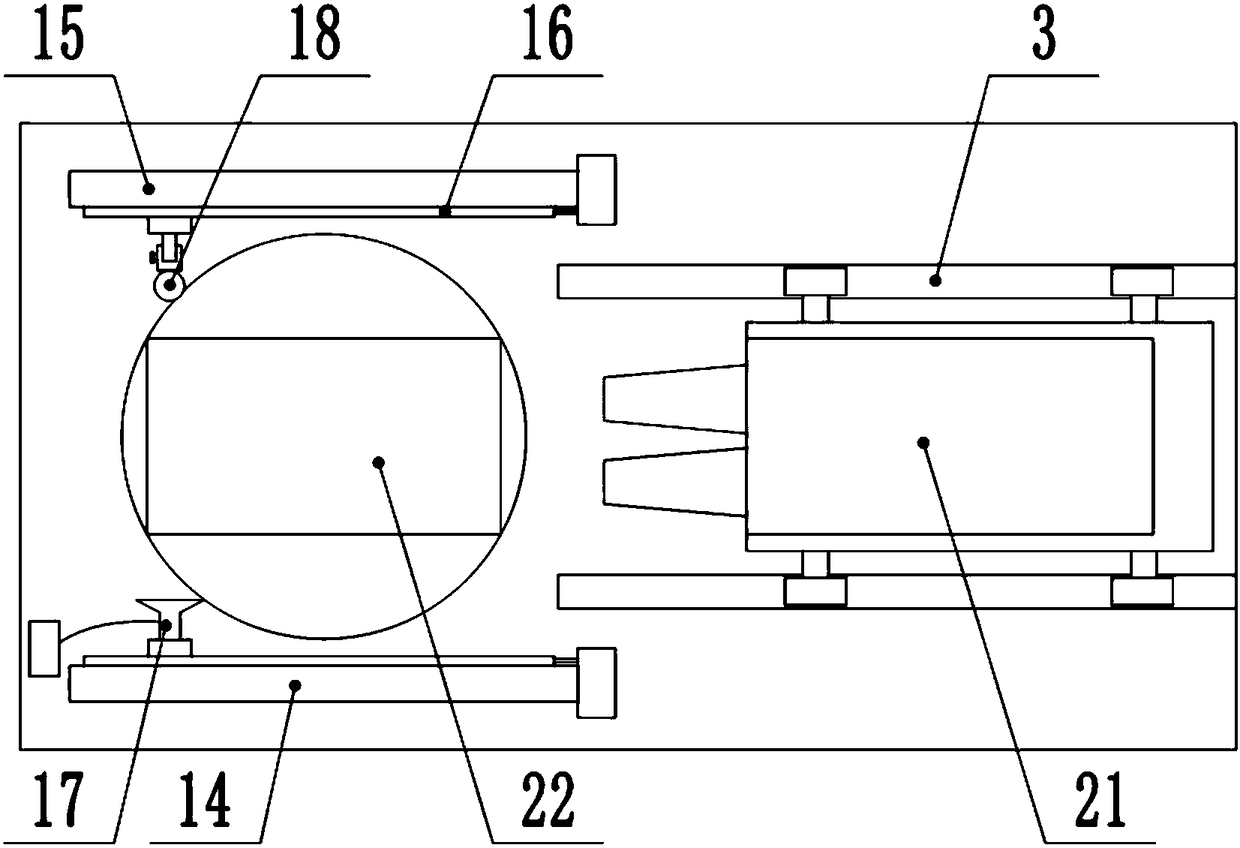

[0016] Such as Figure 1 to Figure 2 As shown, a sand core assembly device in the casting process includes a base 1, one end of the upper surface of the base 1 is provided with a rotating motor 2 and the other end is provided with two first guide rails 3 in parallel, and the rotating motor 2 passes through the vertical The vertically upward rotating shaft is connected with a rotating platform 4, a support platform 5 is provided above the first guide rail 3, and a first pulley 6 is provided at the bottom of the support platform 5, and the first pulley 6 is located in the first guide rail 3 to realize sliding And the sliding direction is close to or away from the rotating motor 2, the middle position of the upper surface of the support platform 5 is provided with a lifting cylinder 7, and the top of the telescopic rod of the lifting cylinder 7 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com