A static pressure tool post grating ruler installation structure

A technology of grating scale and tool holder, which is applied in the field of numerical control, can solve the problems of oil prevention, etc., and achieve the effect of improving stability and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

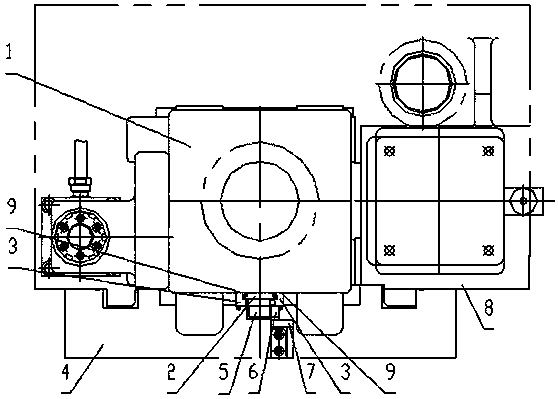

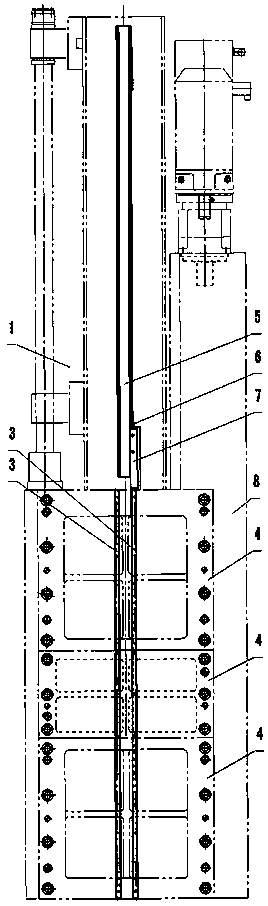

[0011] Such as figure 1 and figure 2 As shown, the grating ruler installation structure of the static pressure tool post in this embodiment includes a ram 1, a transition plate for installing the grating ruler to a fixed length 2, a guide plate 3, a front pressure plate of the rotary slide 4, a grating ruler to a fixed length 5, and a grating ruler Moving ruler 6, grating ruler moving ruler mounting bracket 7, rotary slide seat 8 and felt 9, grating ruler fixed length installation transition plate 2 is installed on ram 1 with screws, grating ruler fixed length 5 is installed grating ruler fixed length installation transition plate 2, the length of the transition plate 2 for the grating ruler is slightly longer than the length of the grating ruler 5, and can completely contain the grating ruler 5; the front pressure plate 4 of the rotary slide seat is provided with a guide plate 3, and the length of the guide plate 3 is The length of the front pressure plate 4 of the rotary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com