Damping alloy and dot matrix composite enhanced vibration suppression structure

A technology of damping alloy and composite reinforcement, which is applied in additive processing, additive manufacturing, instruments, etc., can solve problems such as single function and heavy structure weight, and achieve the effects of reducing base weight, high vibration resistance, and improving high-precision stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

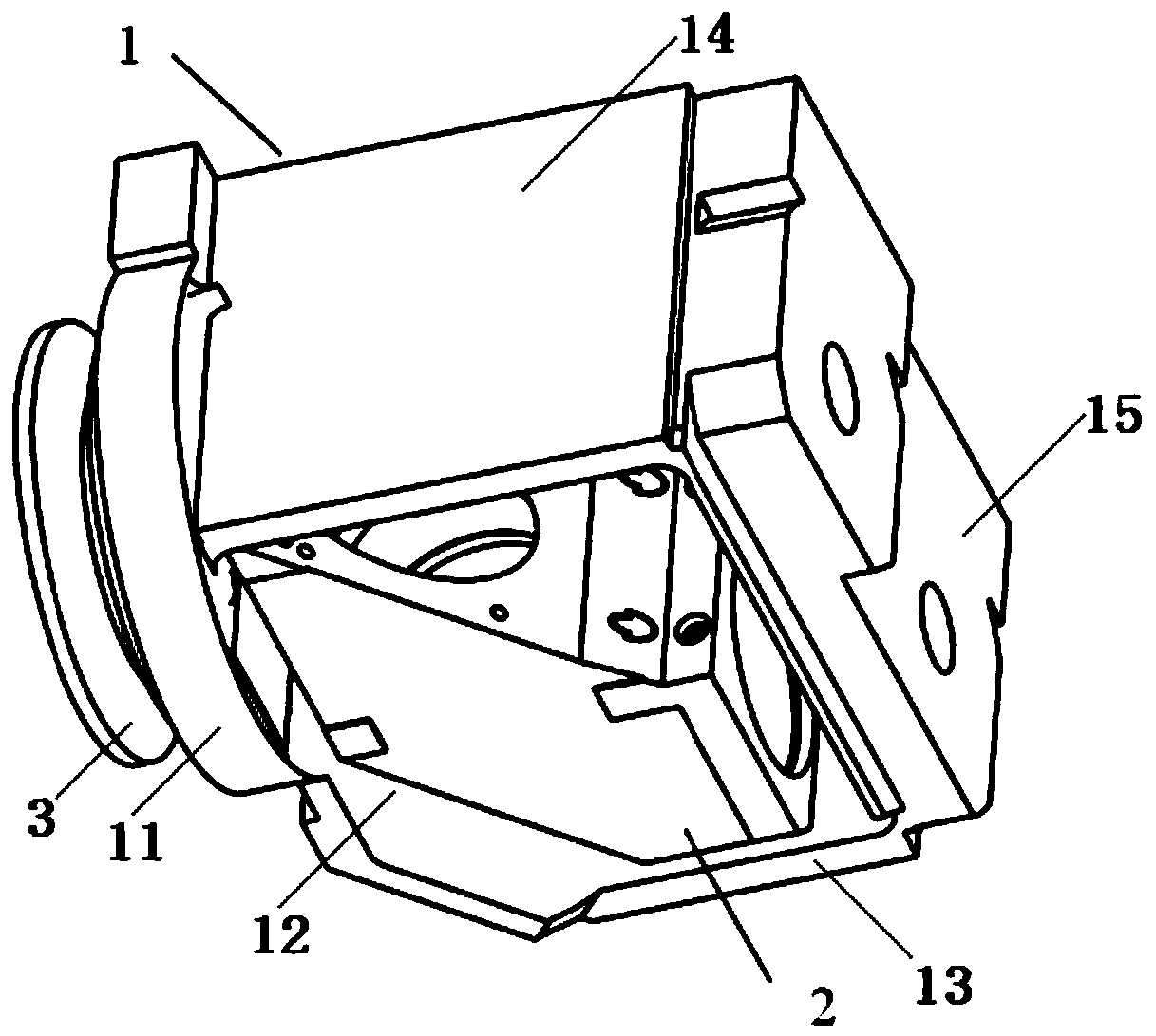

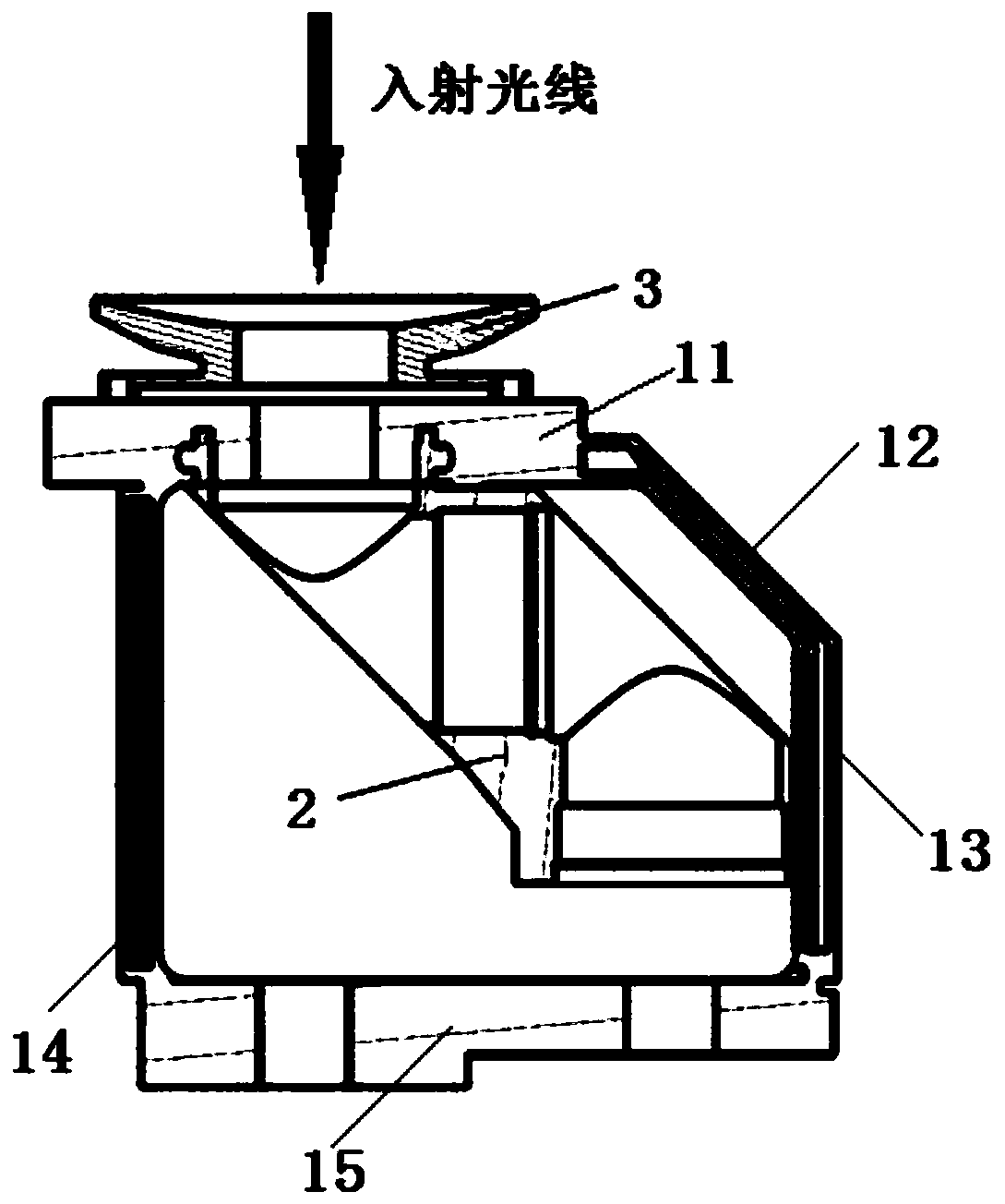

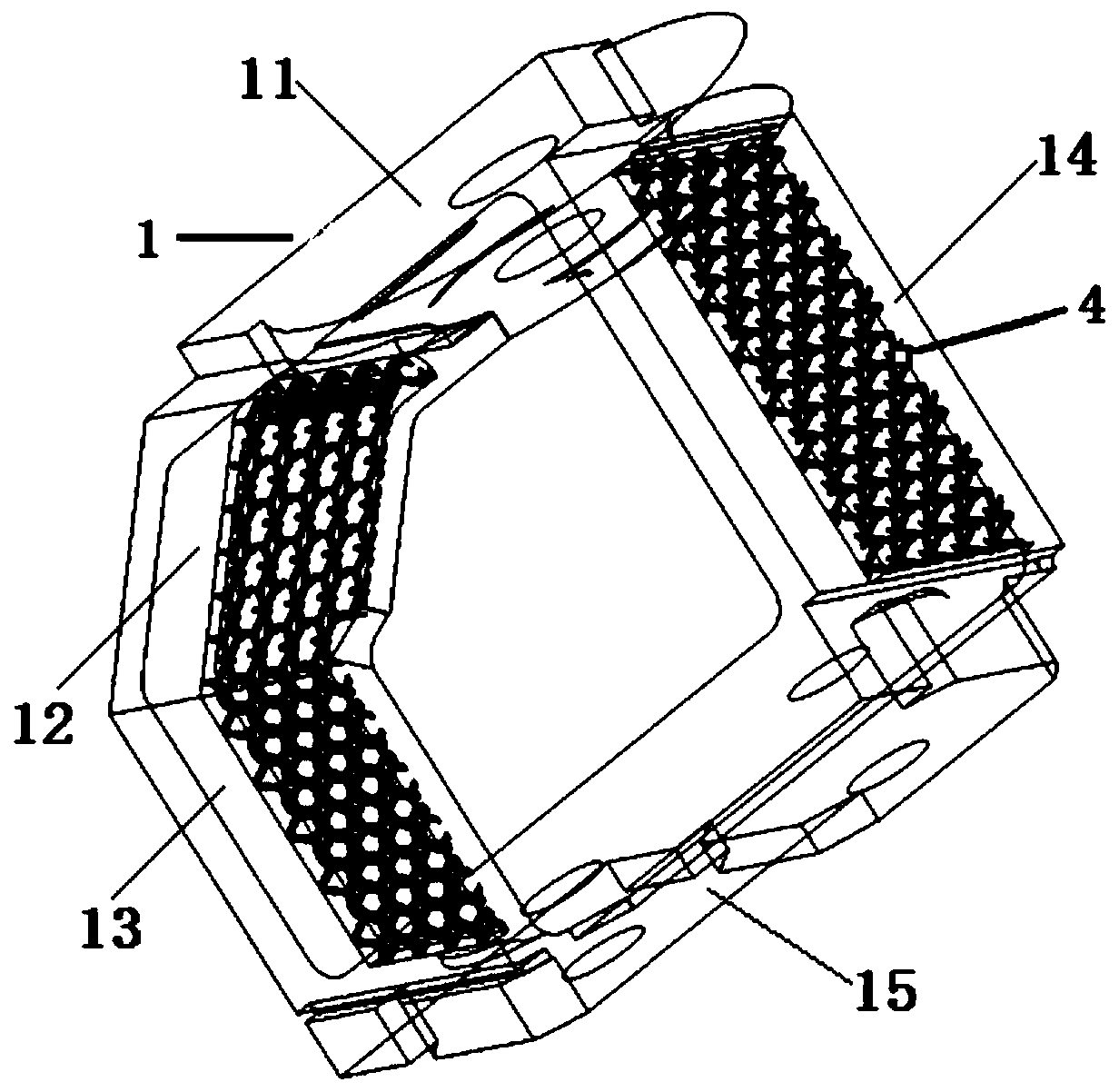

[0035] Such as figure 1 with figure 2 As shown, a damping alloy and lattice composite enhanced vibration suppression structure includes: a Mn-Cu damping alloy base 1 and a lattice structure 4 on the Mn-Cu damping alloy base 1 .

[0036] The Mn-Cu damping alloy base 1 has a heptahedral cavity structure. The heptahedron includes a cuboid base and an inclined support side wall 12. The cuboid base includes two sealed side walls and an optical installation side wall 11 and an imaging support side wall 13 enclosed in sequence. 1. The guide installation side wall 15 and the top support side wall 14 are provided with an inclined support side wall 12 at the junction of the optical installation side wall 11 and the imaging support side wall 13 .

[0037] The optical installation side wall 11 is provided with a through hole, the optical lens 3 is a circular convex lens, and the circular convex lens is fixed on the center of the circular optical base installation platform, and the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com