Constant-temperature structure for belt transmission main shafts

A technology of belt transmission and transmission spindle, which is applied in the direction of driving devices, metal processing machinery parts, maintenance and safety accessories, etc., which can solve the problems of deterioration of machining accuracy of machine tools, temperature rise of transmission parts, and large temperature rise, so as to improve precision The effect of stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

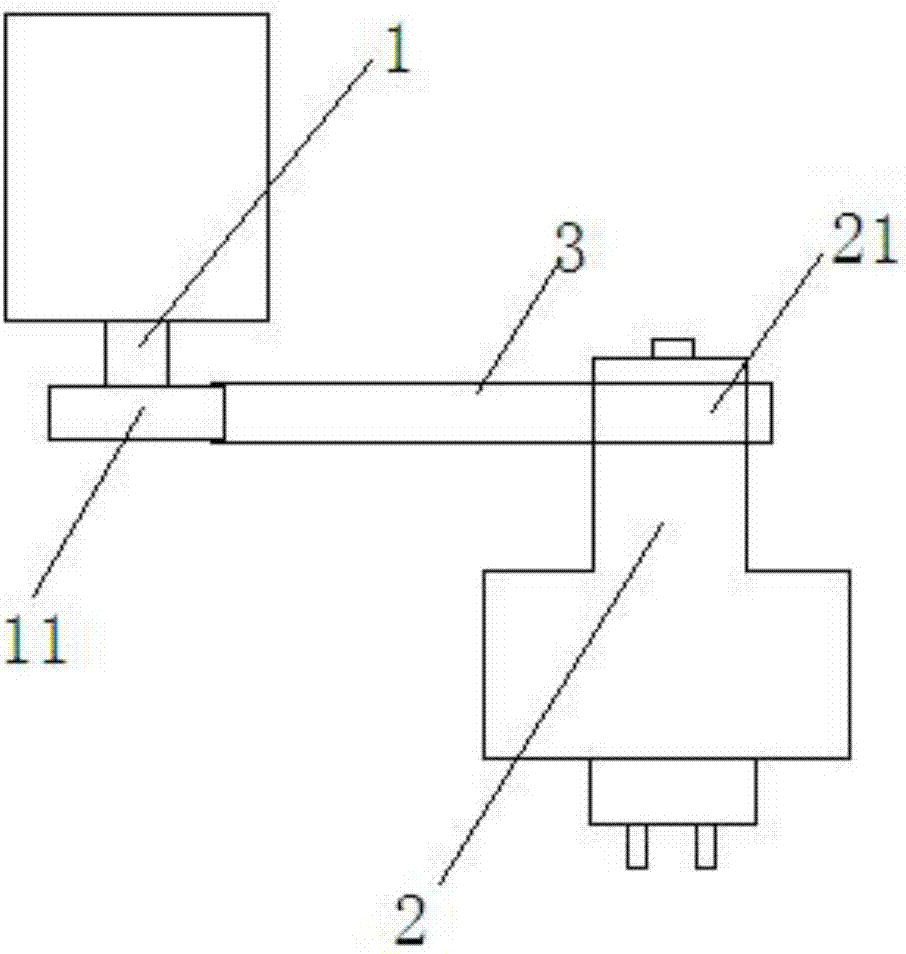

[0014] Such as figure 1 As shown, the existing CNC machine tool spindle power transmission adopts a pulley belt transmission structure. This structure has the characteristics of convenient installation and small impact on transmission abnormalities. The heat generated by the deformation will cause the temperature of the transmission parts to rise rapidly. Due to the temperature rise, the transmission parts such as the spindle will be deformed and lose their own precision.

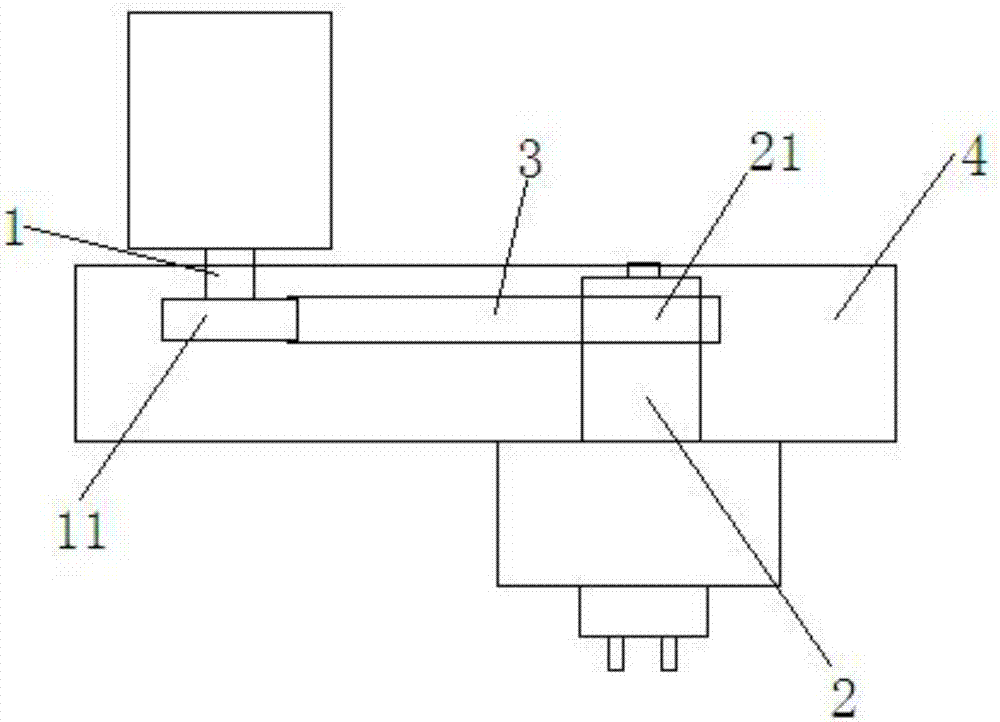

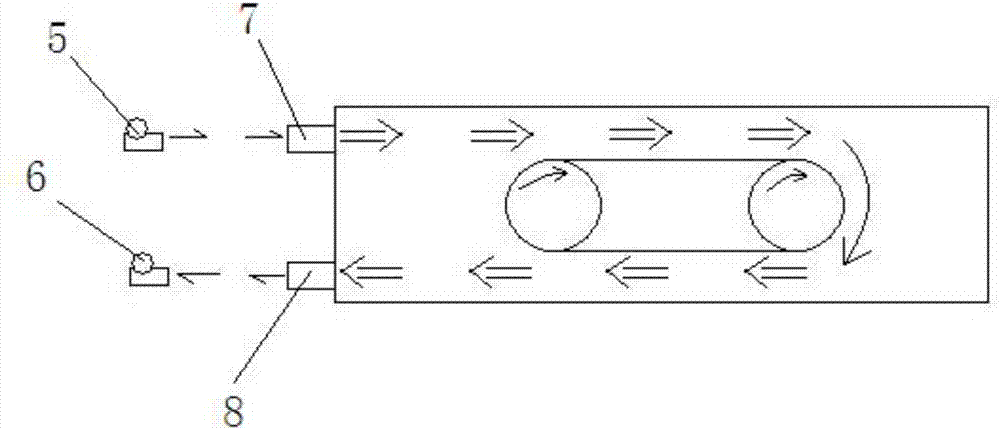

[0015] In order to ensure the stable accuracy of the machine tool and reduce the accuracy change of the main shaft due to thermal deformation, the structure of the transmission part is modified, as follows: Figure 2-3 As shown, a constant temperature structure of a belt drive main shaft includes a first transmission main shaft 1, a second transmission main shaft 2, a belt 3, a casing 4, a first pulley 11 and a second pulley 21; A first pulley 11 is installed, and a second pulley 21 is installed on the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com