Hot galvanizing system with high working efficiency

A hot-dip galvanizing, high-efficiency technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of high cost, unfavorable rapid turnover of plated parts, complicated hanging basket manufacturing, etc., and achieve processing costs. Low, simple structure, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

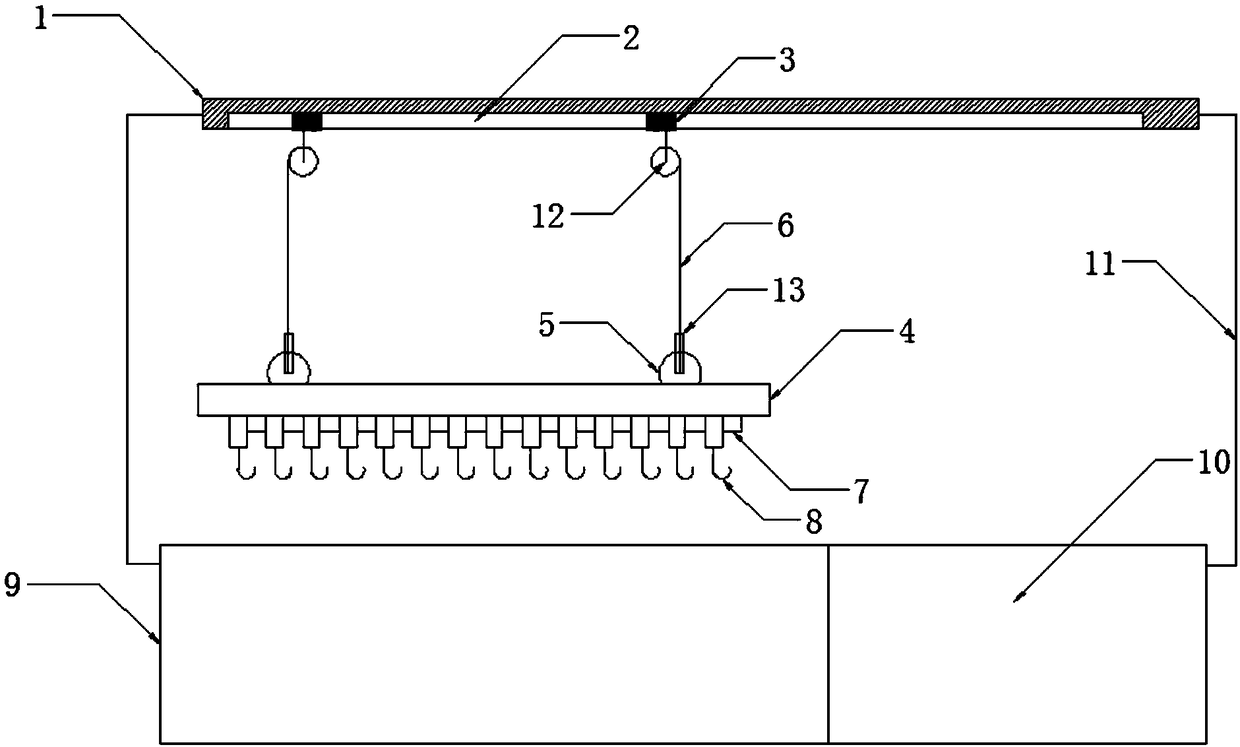

[0014] Such as figure 1 As shown, a hot-dip galvanizing system with high operating efficiency of the present invention includes a beam 1, an electric slide rail 2, an electric slide table 3, a hanging plate 4, a hanging ring 5, a steel wire rope 6, a chain transmission mechanism 7, a hook 8, a heating Galvanizing tank 9, loading and unloading platform 10, bracket 11, electric shaft 12, hook 13;

[0015] The hot-dip galvanizing tank 9 and the loading and unloading platform 10 are arranged adjacently. The crossbeam 1 spans the hot-dip galvanizing tank 9 and the loading and unloading platform 10 is fixedly arranged on the top of it through the bracket 11. The bottom end of the crossbeam 1 is provided with an electric slide rail 2. The slide rail 2 is provided with at least two electric sliding tables 3 which are slidably connected thereto. The electric sliding table 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com