A universal automatic air supply joint

A universal, automatic technology, applied in the direction of pipes/pipe joints/fittings, gas/liquid distribution and storage, connections with fluid cut-off devices, etc., can solve the problem of low work efficiency, poor automation, and increased unsafe factors and other problems, to achieve the effect of good sealing effect and strong receiving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, without limiting the scope of protection.

[0036] A universal automatic air supply joint is characterized in that the device includes: a receiving mechanism, a transmitting mechanism, a balance mechanism and a mounting bracket. The structural diagram of the joint is shown in figure 1 shown.

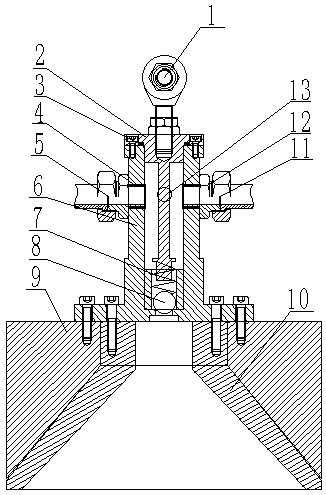

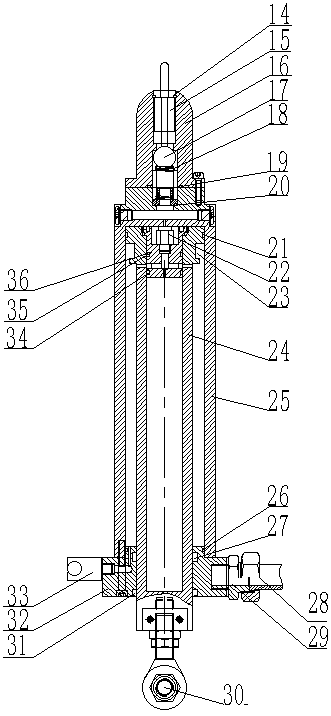

[0037] Such as figure 2 As shown, the receiving mechanism includes: an upper joint bearing 1, a receiving mechanism base 2, a receiving mechanism spool 6, a steel ball compression spring 7, a steel ball 8, a receiving mechanism counterweight 9, and a guide cone 10. Such as Figure 6 As shown, a circle of split holes 49 of the same size is provided in the cavity of the valve core 6 of the receiving mechanism, and the split holes 49 intersect with the inner hole. The steel ball 8 is placed at the valve port in the cavity of the valve core 6 of the receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com