Intelligent track grinding wagon

A technology for grinding cars and rails, applied in the directions of grinding machines, grinding frames, grinding beds, etc., can solve problems such as affecting the driving quality, and achieve the effects of avoiding debris splashing, improving reliability, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

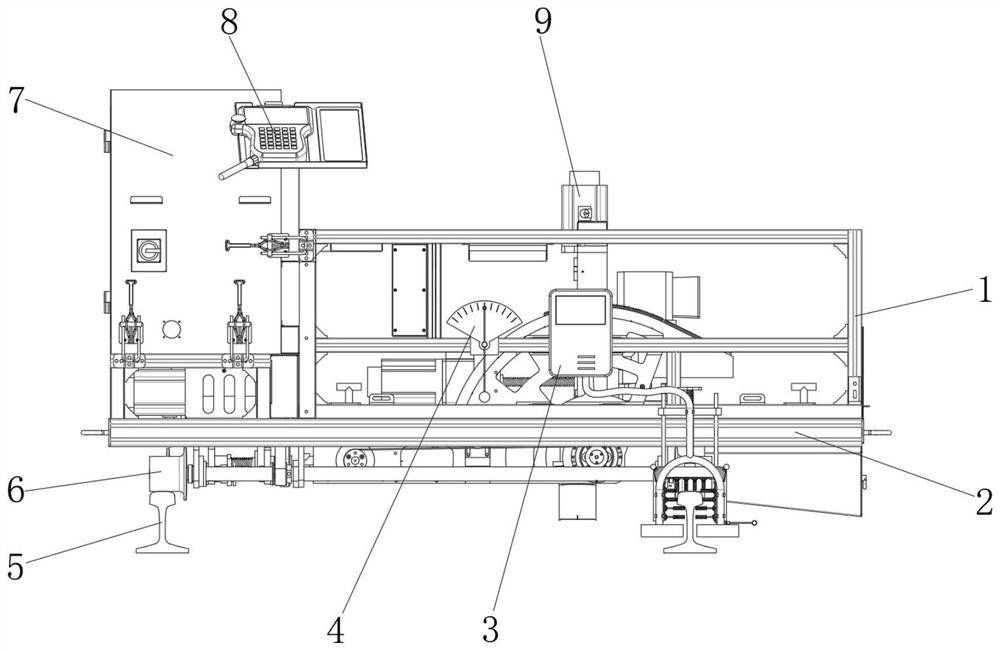

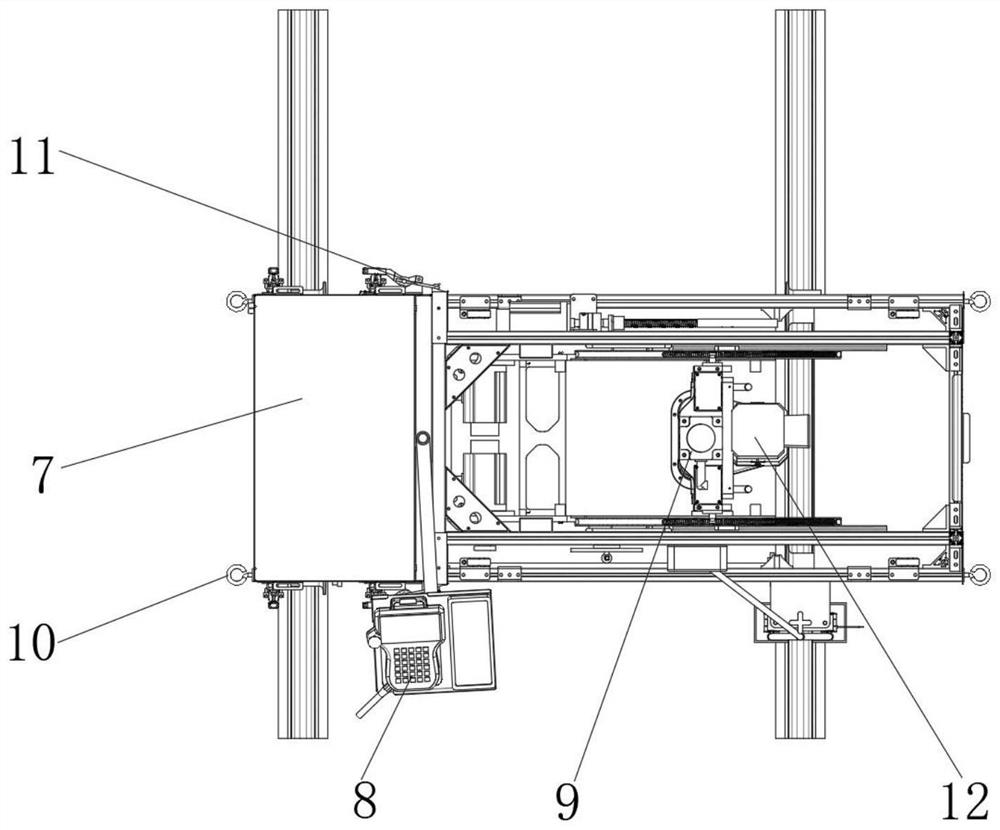

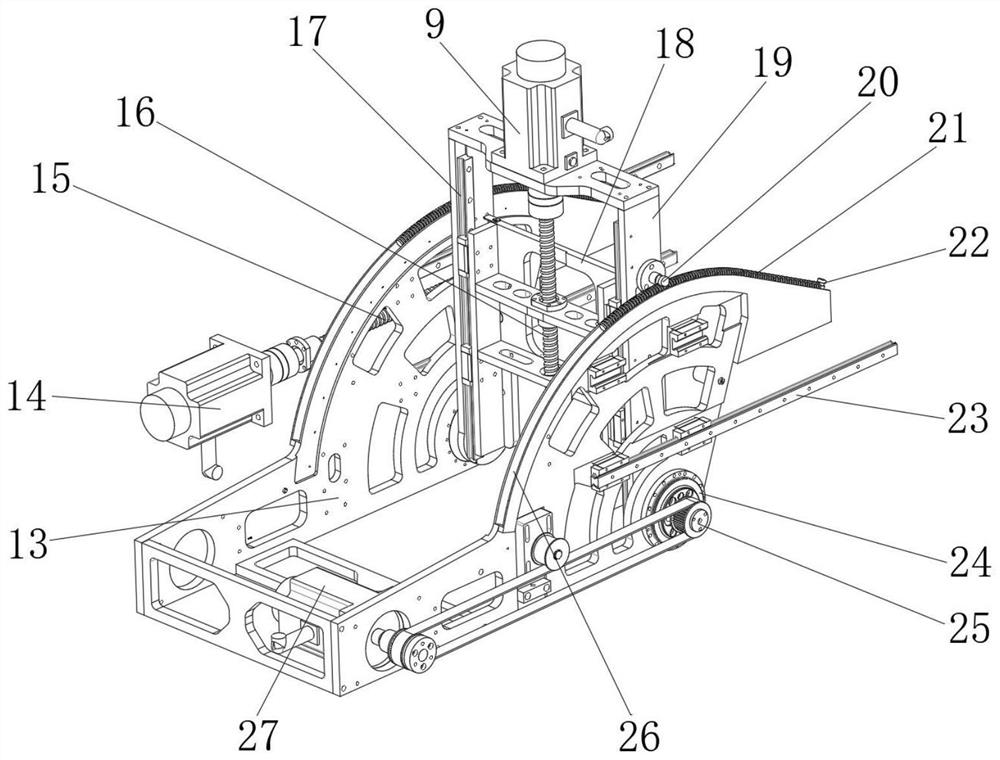

[0046] A kind of intelligent track polishing car, such as Figure 1-10 As shown, it includes an upper frame 1 and a lower frame 2. The upper frame 1 is detachably installed on the top outer wall of the lower frame 2. A cleaning mechanism is provided on one side of the upper frame 1. The cleaning mechanism includes a base plate 54 and an upper splint 60. And the side splint 45, the top outer wall of the upper splint 60 is rotatably connected with an adjustment stud 41, the adjustment stud 41 is screwed to the inner wall of the base plate 54, the base plate 54 is fixed to the outer wall of the upper frame 1 side by screws, and the upper splint 60 The top is fixed with a guide rod 42, the guide rod 42 is slidably connected to the inner wall of the base plate 54, and the top ends of the two side splints 45 are rotatably connected to the two ends of the upper splint 60, and the adjacent outer walls of the two side splints 45 and the upper splint 60 are mutually compatible. The incl...

Embodiment 2

[0057] A kind of intelligent track polishing car, such as Figure 5 As shown, in order to be able to adapt to the rail 5; this embodiment makes the following improvements on the basis of Embodiment 1: a span adjustment mechanism is installed on the lower frame 2, and the span adjustment mechanism includes a span adjustment motor 38 and a span adjustment Wheel 39, the inner wall on both sides of the lower frame 2 is fixed with a fixed plate 35 by screws, the span adjustment motor 38 is fixed on the outer wall of one side of the fixed plate 35 by screws, and the output end of the span adjustment motor 38 is synchronized by span adjustment. The wheel assembly 34 is rotatably connected with a span adjustment stud 36, and the span adjustment stud 36 is threadedly connected with a positioning plate 37, and the span adjustment wheel 39 is rotatably mounted on the positioning plate 37 through a shaft away from the fixed plate 35 One side of the outer wall of the positioning plate 37 i...

Embodiment 3

[0060] A kind of intelligent track polishing car, such as Figure 11 , Figure 12 As shown, in order to improve the dust collection effect; this embodiment makes the following improvements on the basis of embodiment 1 or 2: the outer wall of one side of the collection box 44 is integrally provided with a shield 73, and the port of the air pipe 40 is bonded with a spherical Head 72, the outer surface of spherical head 72 is provided with evenly distributed through holes 70, and the outer wall of the top of the collection box 44 is fixed with a shroud 69 by screws, and the position of the shroud 69 is adapted to the dust suction hole 51; The outer wall of the adjacent side of the box 44 is embedded with a rollable ball 71; through the arrangement of a shroud 69 and other structures, it is convenient to better guide the dust into the air pipe 40, and the spherical head 72 is set to limit the air pipe 40 on the one hand. On the other hand, the permeability of one end of the air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com