Hub polishing device

A technique for polishing devices and hubs, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding workpiece supports, etc., can solve problems such as harsh working environments and serious environmental pollution, and achieve the goal of ensuring polishing quality and improving polishing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

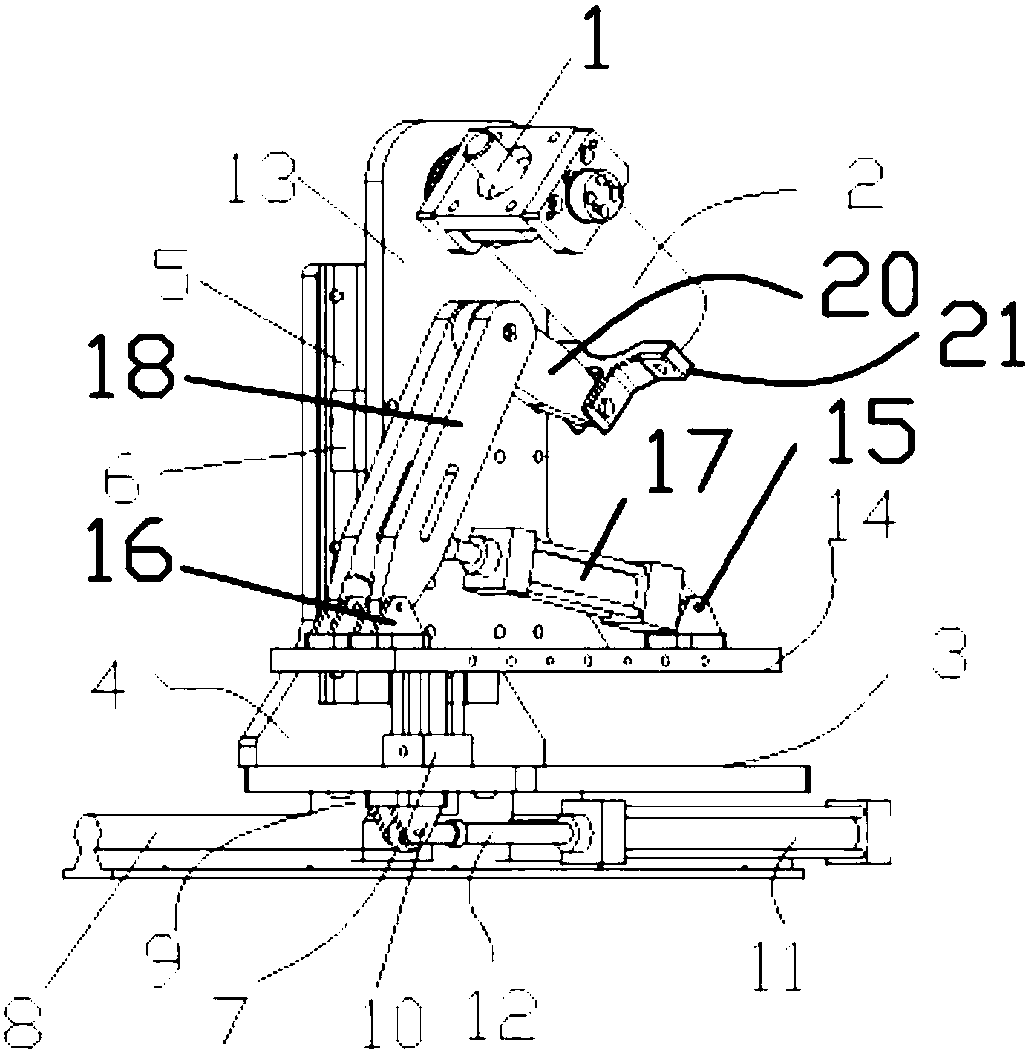

[0019] In order to illustrate the technical scheme proposed by the present invention conveniently, figure 1 It is a schematic diagram of the structure after removing a side plate 1 and a side plate 2 for this mechanism.

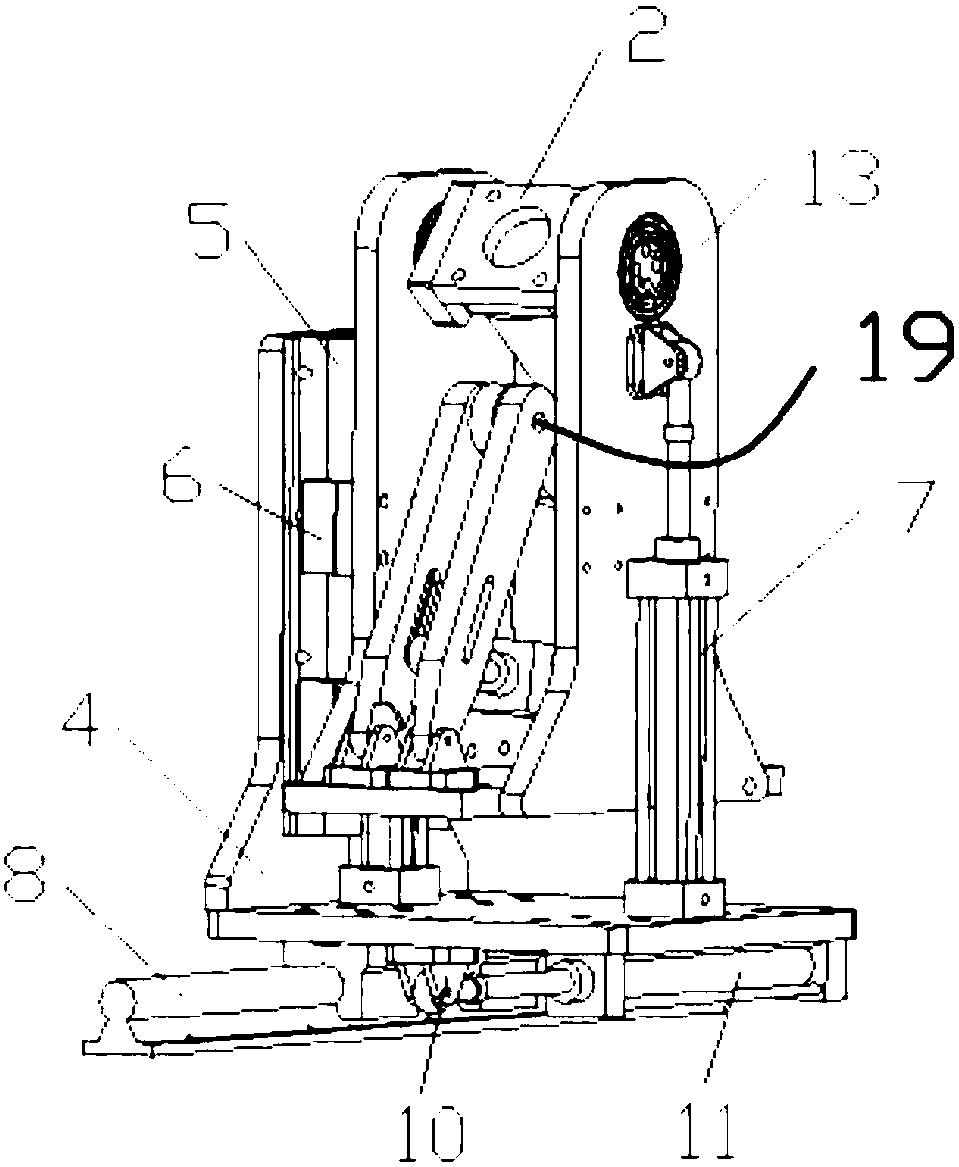

[0020] figure 2 One of the side plates is removed for this mechanism—a schematic diagram of the structure.

[0021] As above figure 1 and 2 As shown, the hub polishing device includes a base plate-3, a horizontal mechanism capable of driving the base plate-3 to move horizontally is provided below the base plate-3; two side plates-4 are vertically installed on both sides above the base plate-3 , the inner sides of the two side plates-4 are provided with a guide rail-5, each guide rail-5 is equipped with a slider-6, each of the slider-6 is vertically installed above the bottom plate-3 Driven by a lifting cylinder 7 to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com