Cloth and abrasive cloth double-layer intelligent pipe rolling mechanism

A technology of cloth emery cloth and tube, which is applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of lack of internal support of cloth coil, affecting the quality of cloth emery cloth, and poor adhesive quality of abrasive cloth. , to achieve the effect of overall automatic production and processing, novel structure and fast overall operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

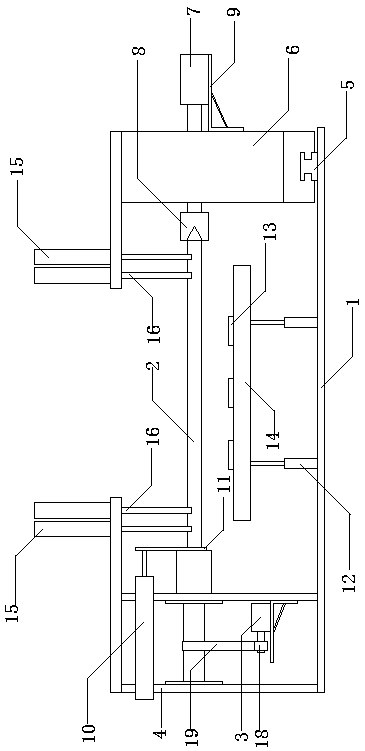

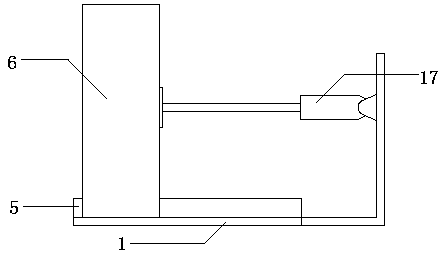

[0020] Such as figure 1 Shown is a schematic structural diagram of the present invention, the present invention is a double-layer intelligent rolling mechanism for cloth abrasive cloth, including a frame 1, a cloth abrasive cloth tube mandrel 2, a pipe rolling motor 3, a material return mechanism, a ejector rod mechanism and a heating mechanism , also includes the hold-down mechanism

[0021] The two ends of the frame 1 are respectively the coiled tube end and the ejector rod end, and are respectively provided with a coiled tube frame 4 and a sliding guide rail 5 .

[0022] The tube rolling motor 3 is arranged at the bottom of the tube rolling frame 4 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com