Method and system for realizing inspection of steel strip punching by machine vision

A machine vision and punching technology, applied in the field of inspection, can solve the problems such as the inability to obtain the image of the punched steel strip, the indeterminate speed of the punching steel strip, and the inability to sample during the production process. , Improve the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

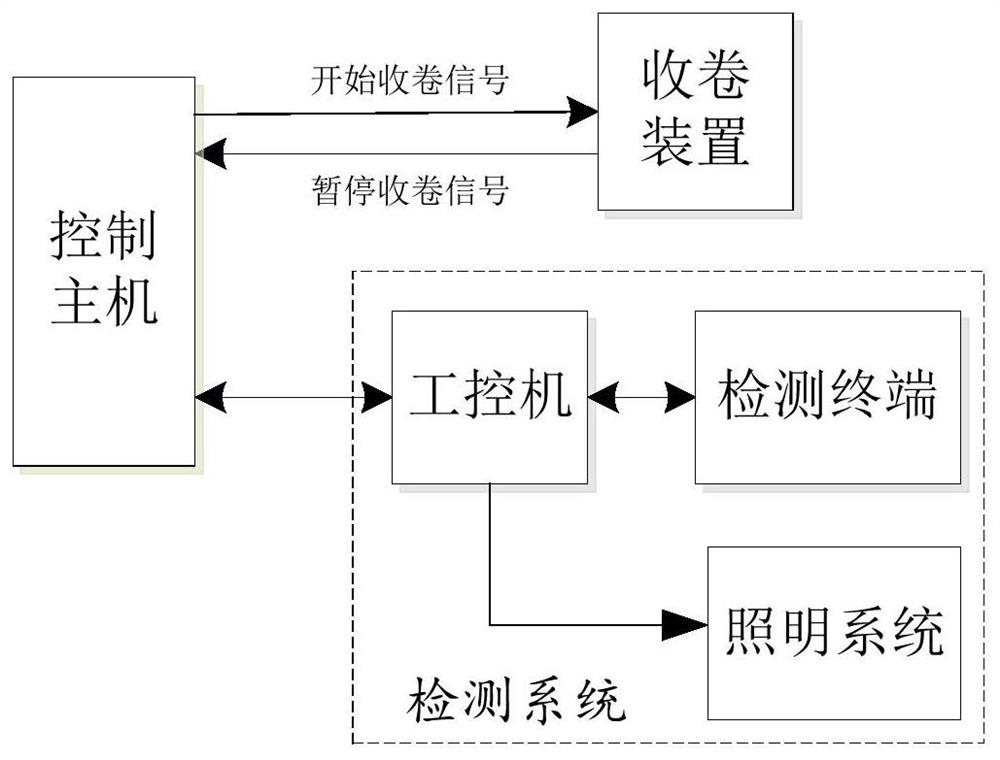

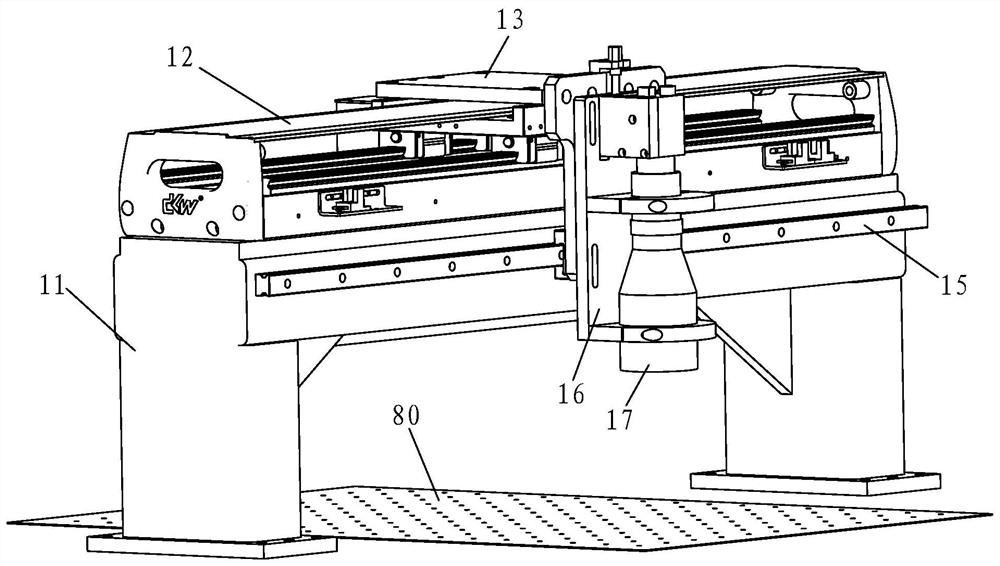

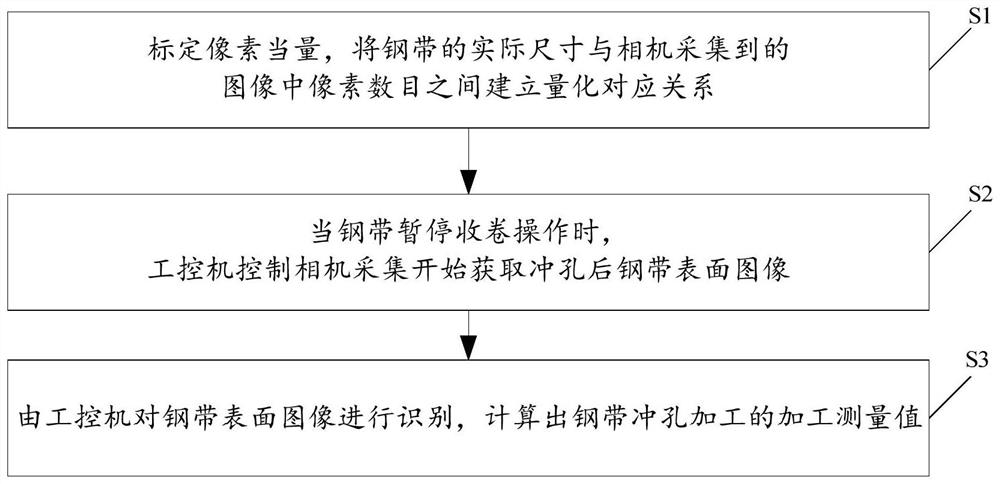

[0032] For this reason, the present invention proposes a kind of method and system that adopts machine vision to realize steel strip punching processing detection, by means of moving machine vision, the images of the upper surface of the punched steel strip after punching are sampled in stages, and the upper surface of the steel strip is analyzed. The image is processed and analyzed to obtain the detection result.

[0033] The steel strip punching processing detection system proposed by the present invention mainly includes an industrial computer, at least one detection terminal based on motion machine vision and a lighting system located below the punched steel strip. The detection terminal and the lighting system are both Connected with the industrial computer, the lighting system provides a light source with stable brightness and no flickering so that the detection terminal can collect the image of the upper surface of the punched steel strip.

[0034] The winding device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com