A kind of effervescent air-suspension proppant for slick water fracturing and preparation method thereof

A technology for hydraulic fracturing and proppant, which is applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of reducing reservoir conductivity, falling off of proppant aggregate, and failure of suspension, etc. Achieve the effect of increasing collision and contact probability, reducing screenout, and increasing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

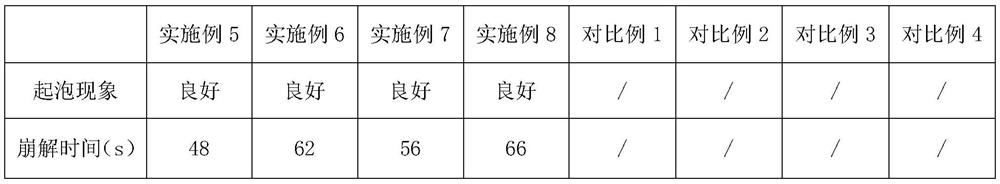

Examples

Embodiment 1

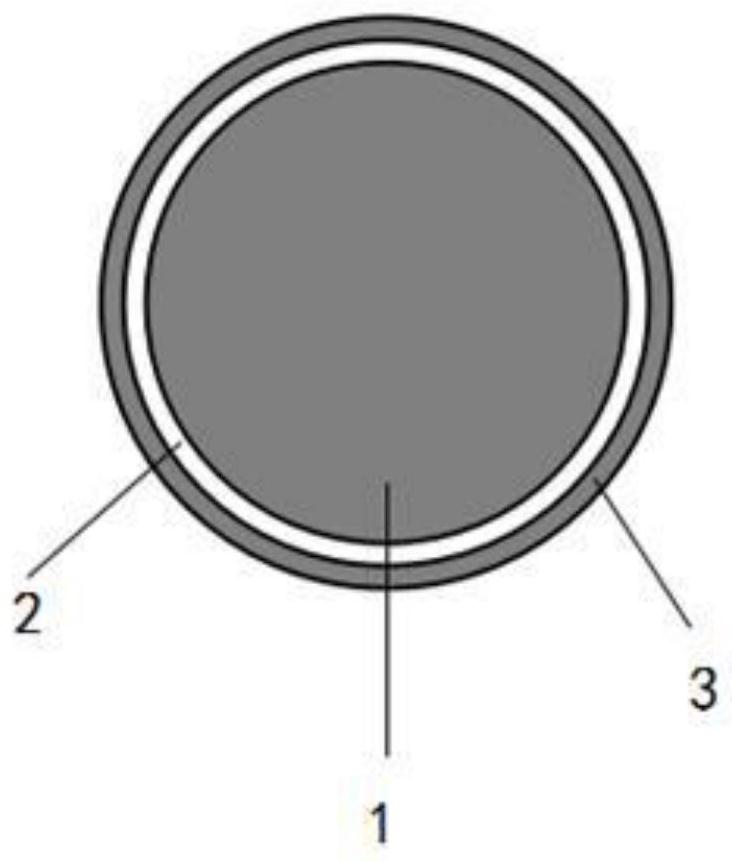

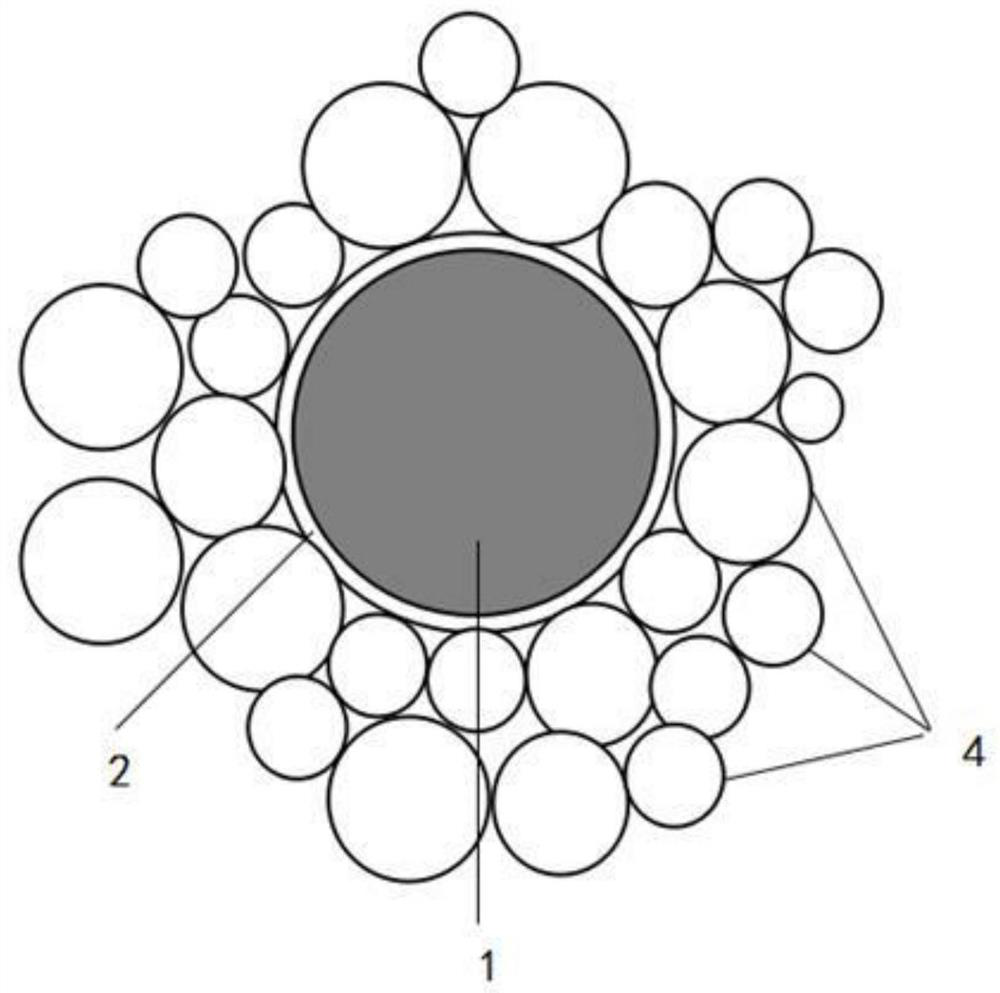

[0046] In order to overcome the problems of the prior art, this embodiment provides a figure 1 The shown effervescent air-suspension proppant for slick water fracturing includes aggregate particles 1, the outer layer of the aggregate particles 1 is provided with an inner coating 2 and an outer coating 3, and the inner coating 2 is located at Between the outer layer of aggregate particles 1 and the outer layer 3 .

[0047] Further, the aggregate particles are quartz sand or ceramsite, with a particle size ranging from 0.125 mm to 2.0 mm.

[0048] Preferably, the aggregate particles are selected from quartz sand for fracturing or ceramsite for fracturing after processes including water washing or pickling, and grading, and the particle size ranges from 0.212 mm to 0.85 mm.

[0049] Preferably, the inner coating 2 is a hydrophobic and air-philic coating, and the hydrophobic and air-philic coating is prepared by curing a hydrophobic and air-philic emulsion.

[0050] Preferably, th...

Embodiment 2

[0054] On the basis of Example 1, this example provides the effervescent air-suspension proppant for slick water fracturing. The effervescent agent includes the following components: by mass percentage, 20-40% alkaline agent, 10-20% acidic agent, 1-10% binder, and the balance is absolute ethanol.

[0055] Further, the alkaline agent is carbonate or bicarbonate.

[0056] Preferably, the alkaline agent is one or a mixture of several of ammonium bicarbonate, potassium carbonate, sodium carbonate, potassium bicarbonate, sodium bicarbonate, and ammonium carbonate in any proportion.

[0057] More preferably, the alkaline agent is sodium bicarbonate or sodium carbonate.

[0058] The acidic agent is organic acid, acid anhydride or acid salt.

[0059] Preferably, the acidic agent is one or a mixture of several of oxalic acid, citric acid, maleic acid, sorbic acid, malic acid, gluconic acid, tartaric acid, and adipic acid in any proportion.

[0060] More preferably, the binder is a p...

Embodiment 3

[0071] On the basis of Example 1, this example provides the effervescent air-suspension proppant for slick water fracturing. The hydrophobic and air-friendly emulsion includes the following components: by mass percentage, 20-50% contains Fluorine polymer monomer, 5-25% polymer binder, 3-10% silane coupling agent, 3-10% surfactant, the balance is deionized water

[0072] Further, the fluorine-containing polymerizable monomer is fluorine-containing acrylate.

[0073] Preferably, the fluorine-containing acrylate is hexafluorobutyl acrylate, hexafluorobutyl methacrylate, tridecafluorooctyl methacrylate, dodecafluoroheptyl acrylate, dodecafluoroheptyl methacrylate, methyl One of trifluoroethyl acrylate.

[0074] More preferably, the fluorine-containing acrylate is dodecafluoroheptyl methacrylate.

[0075] The polymer binder is one of lauryl methacrylate, octadecyl methacrylate, hydroxypropyl acrylate, hydroxyethyl acrylate, and 2-(dimethylamino)ethyl methacrylate or Several mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com