Device and method to intercept concrete at dense-rib beam post-cast strip

A technology of densely ribbed beams and concrete, which is applied to the processing of building materials, building components, building insulation materials, etc., can solve problems such as bad, inconvenient operation, and uneconomical blocking effects, and achieve low cost, fast construction, and high blocking effects. Good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

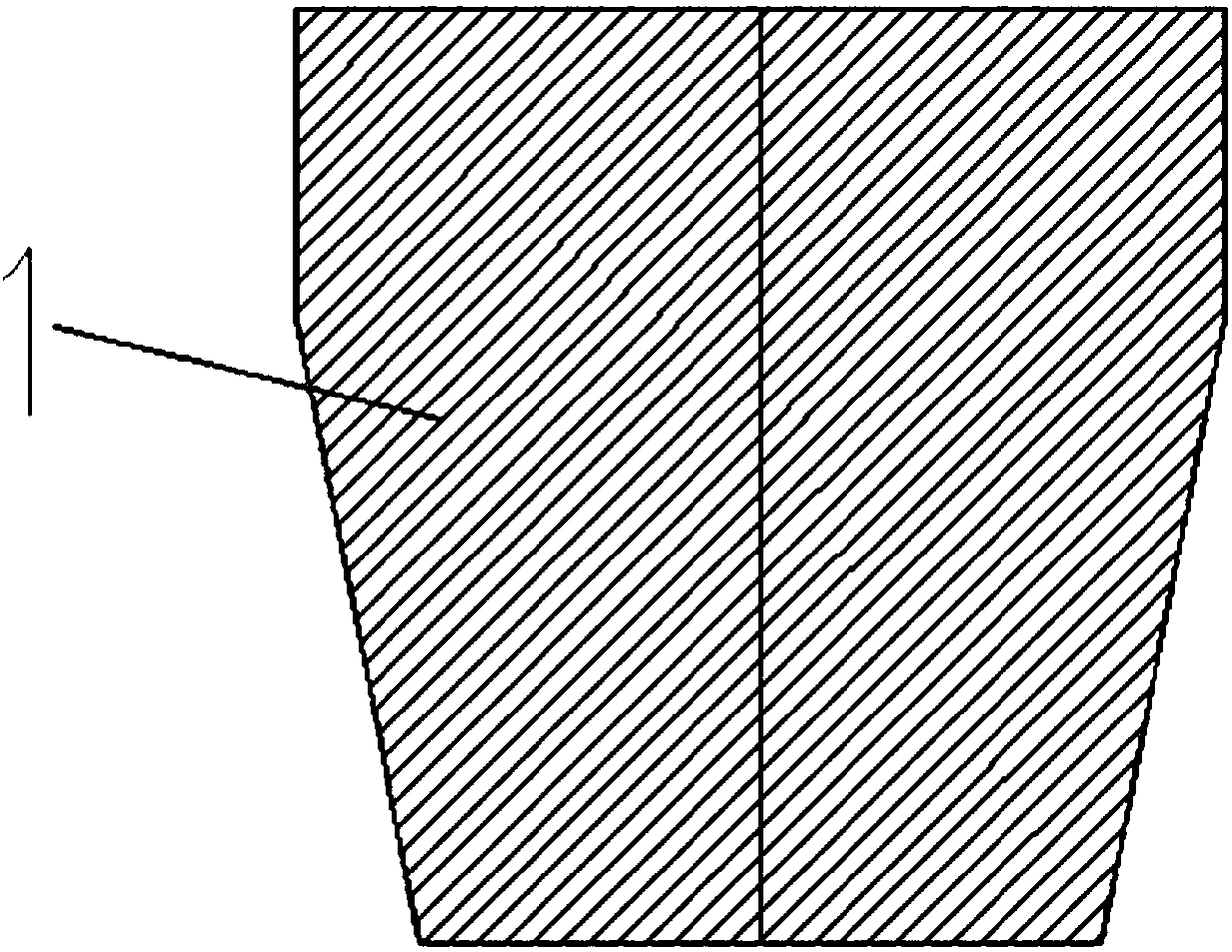

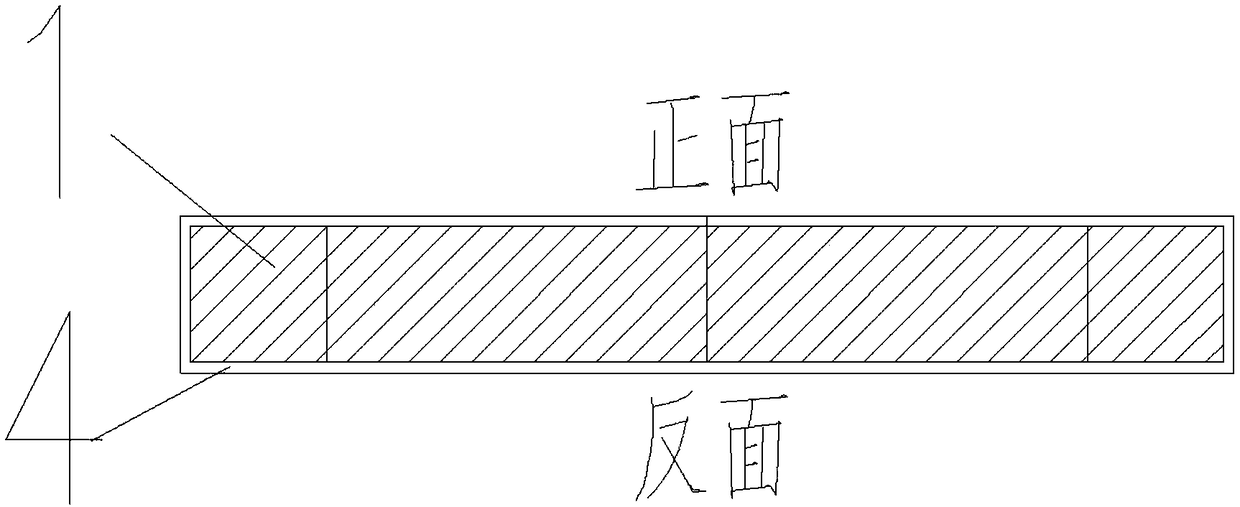

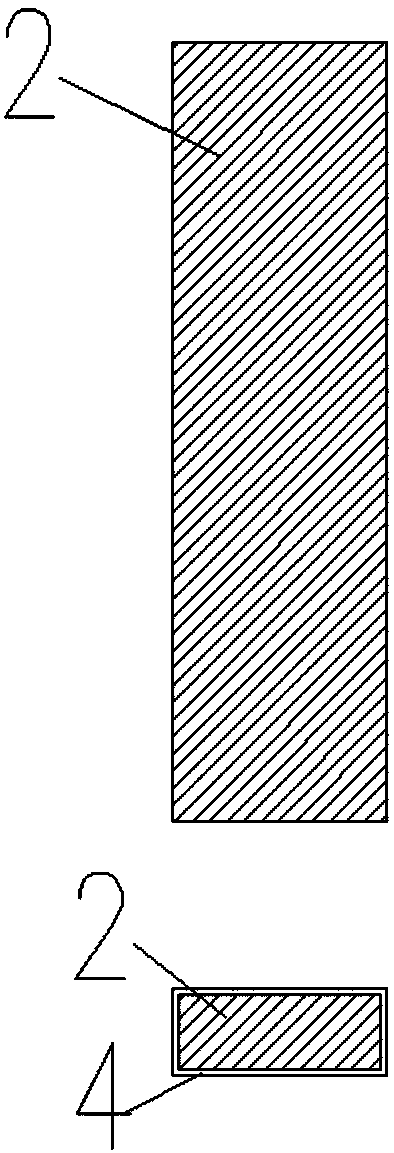

[0043] Such as Figure 1-10 As shown, a concrete blocking device for the post-pouring belt of densely ribbed beams, including a main fence 1, an auxiliary fence 2 and a partition fence 3, is characterized in that: the main fence 1 and the auxiliary fence 2 They are all wrapped with scotch tape 4 . After wrapping with scotch tape 4 , the compressive strength of the main fence 1 and the auxiliary fence 2 can be increased, and the vibration and impact during the pouring of the concrete 12 can be resisted. The separation block 3 is composed of the second dense rib beam stirrup 3b and the dense mesh steel wire mesh 3c, that is, the second dense rib beam stirrup 3b is wrapped with the dense mesh steel wire mesh 3c; The position of the first dense rib beam stirrup 3a is first inserted into the auxiliary fence 2 and close to the first dense rib beam stirrup 3a, and then inserted into the main fence 1, and the front of the main fence 1 (the cut surface of the transparent tape) is close t...

Embodiment 2

[0048] A method for blocking concrete at the post-casting zone of densely ribbed beams, the specific steps are as follows:

[0049] (1) Construction of ribbed floor structure:

[0050] First set up the template support frame body 10, lay and fix the shaping formwork 8 on the formwork support frame body 10, then fill the extruded plastic plate 9 between the bottoms of the shaped formwork 8, paste the transparent tape 4 on the extruded plastic plate 9, and then Bind the upper steel bar 5 of the densely ribbed beam, the first densely ribbed beam stirrup 3a and the lower steel bar 6 of the densely ribbed beam, and finally carry out the construction of the plate steel bar 7;

[0051] (2) Production of foldable main fence 1:

[0052] The main fence 1 is special-shaped, the height is the net size between the upper reinforcement 5 of the dense rib beam and the lower reinforcement 6 of the dense rib beam after the reinforcement of the dense rib beam is bound, and the width is the sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com