Centrifugal ventilator for aero-engine

An aero-engine and ventilator technology, which is applied to engine components, engine lubrication, separation methods, etc., can solve the problems of large lubricating oil consumption and achieve reasonable pressure drop, high separation efficiency, and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

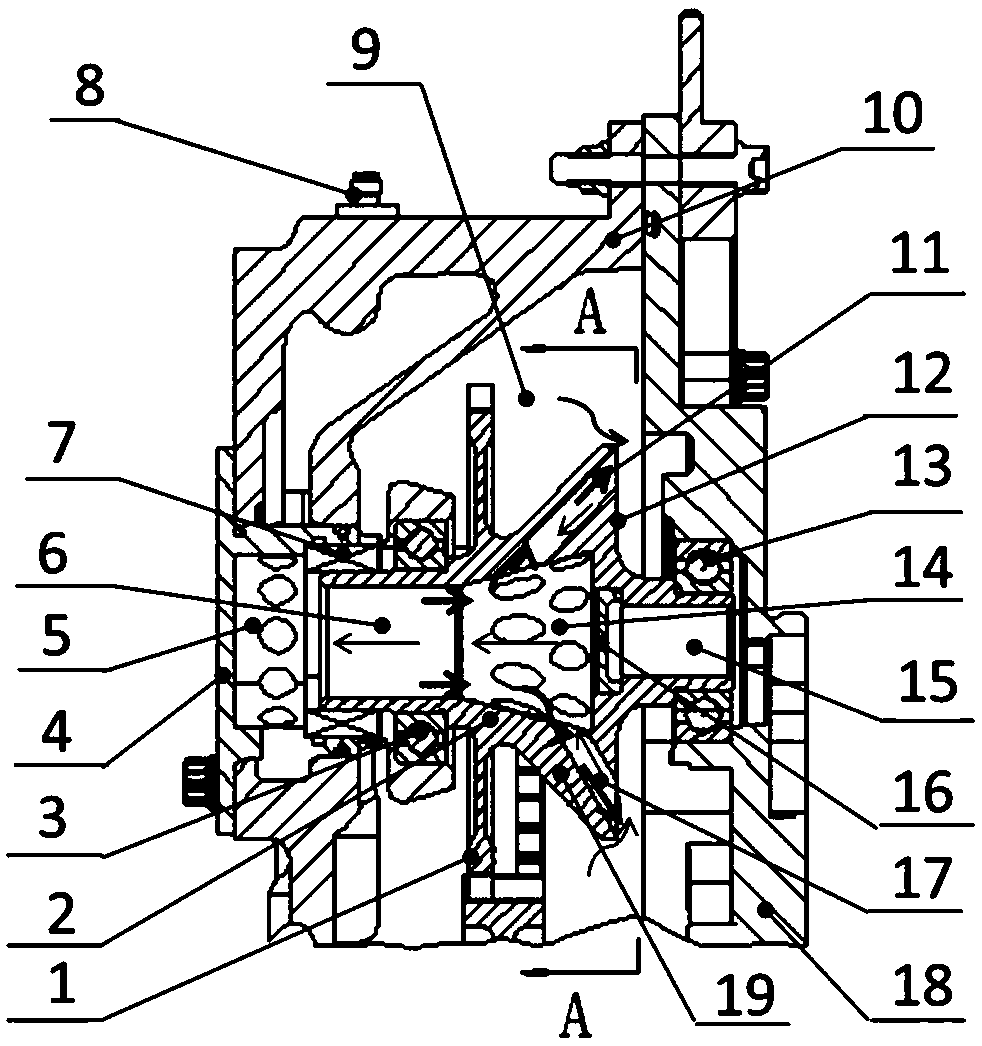

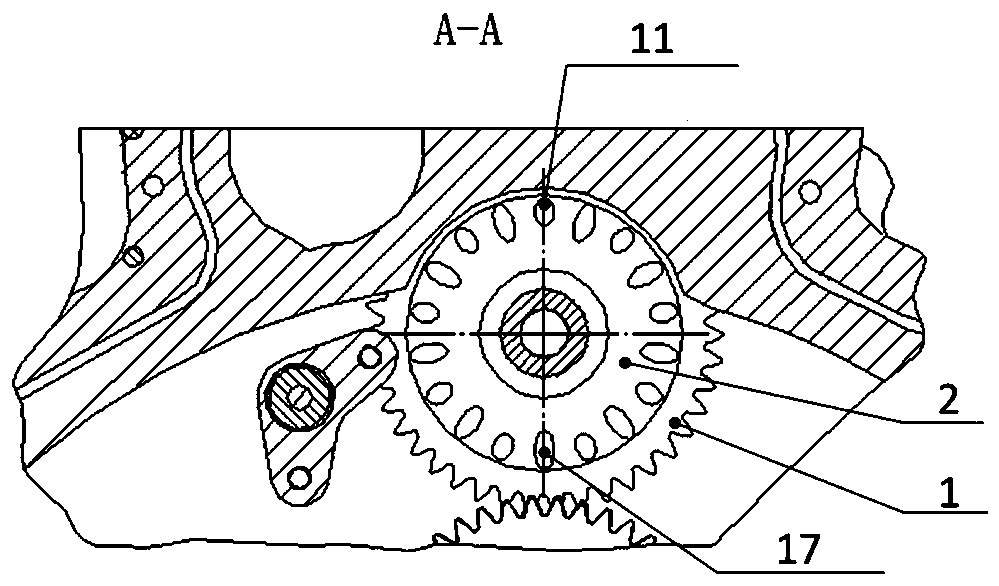

[0024] see figure 1 and figure 2 , an aero-engine centrifugal ventilator is set in the aero-engine accessory transmission casing, and is integrated with the gear 1 in the accessory transmission casing on the same gear transmission shaft 2; the two ends of the gear transmission shaft 2 are respectively provided with The first rolling bearing 3 and the second rolling bearing 13 of the transmission shaft 2; the gear transmission shaft 2 is a hollow structure, and the center of the gear transmission shaft 2 includes three coaxial holes: a central straight hole 6, a central tapered hole 14 and a transmission shaft hole 15, and the central cone The hole 14 is arranged between the central straight hole 6 and the transmission shaft hole 15, and the central straight hole 6 communicates with the small end of the central tapered hole 14; There is an end cover 4 outside; the housing 10 is provided with a joint 8 connected to the external atmosphere, and the end cover 4 is provided with ...

Embodiment 2

[0029] In this embodiment, the structure of the centrifugal ventilator of the aero-engine is basically the same as that of Embodiment 1, the difference being that the length ratio of the central tapered hole 14 at the center of the gear drive shaft 2 to the length of the central straight hole 6 is 1:1.1, The first inclined hole 11 and the second inclined hole 17 intersect and communicate with the conical surface of the central tapered hole 14 at angle b and angle c respectively, where b is 30° and c is 50°; the angle formed by the central tapered hole 14 conical surface and the axis is a , a is 15°; the number of oblique holes 11 is 7, and the aperture is 4mm, and the number of the oblique holes 2 17 is 7, and the aperture is 4mm.

Embodiment 3

[0031] The structure of the aeroengine centrifugal ventilator in this embodiment is basically the same as that of Embodiment 1, the difference being that the length of the central taper hole 14 at the center of the gear drive shaft 2 and the length ratio of the central straight hole 6 are 1:1.2, and the oblique hole One 11 and inclined hole two 17 intersect and communicate with the conical surface of the central conical hole 14 at angle b and angle c respectively, where b is 50° and c is 75°; the angle formed by the conical surface of the central conical hole 14 and the axis is a, a is 10°; the number of inclined holes one 11 is 9, and the aperture is 2mm, and the number of said inclined holes two 17 is 9, and the aperture is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com