Step-by-step pressure reduction method of three-phase fluid as well as design method and application thereof

A fluid and three-phase technology, applied in the field of step-by-step decompression of three-phase fluid, can solve problems such as valve core cavitation wear, economic loss, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

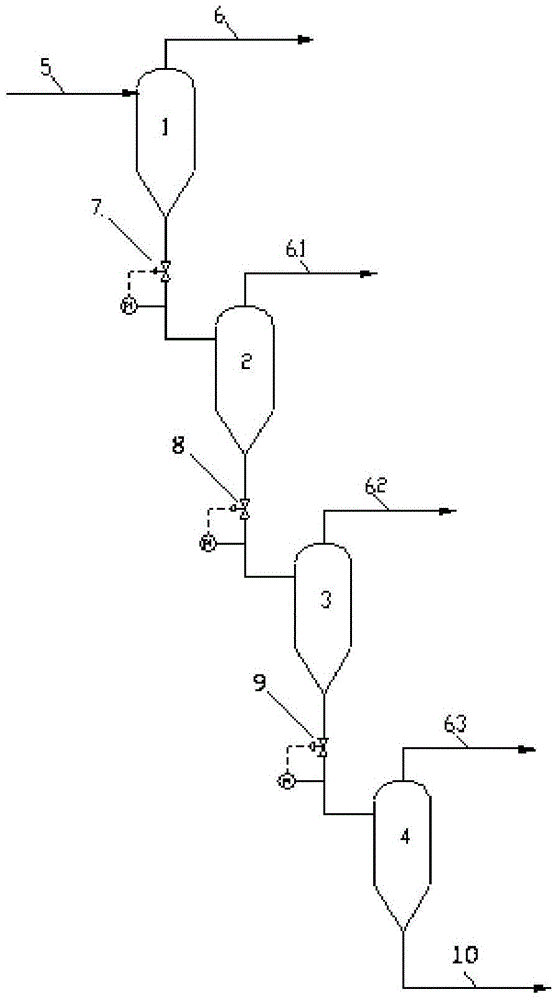

[0020] For further elaborating specific features of the present invention, will combine figure 1 To illustrate.

[0021] This example introduces the decompression separation method for separating gas, liquid and solid three-phase fluids in the separation system of the oil-coal co-refining slurry bed hydrogenation process. Its main purpose is to reduce the three-phase mixed fluid from high pressure to low pressure, so as to Light components are separated in the form of gas phase during the depressurization process. This example only introduces the high temperature and decompression series in the separation system.

[0022] The specific method is to set up four separate buffer tanks connected in sequence, and set a first-stage pressure reducing valve 7, a second-stage pressure-reducing valve 8, and a third-stage pressure-reducing valve 9 on the pipeline between adjacent buffer tanks to realize step-by-step Buck. Set the pressure-taking point after the pressure-reducing valve o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com