Segmented blades, method of connecting segmented blades and wind turbine generating unit

A blade and segment technology, applied in the field of wind turbines, can solve the problems of low reliability, increased blade weight, low performance of structural adhesive, etc., and achieves the effect of high connection reliability and reduced fatigue load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

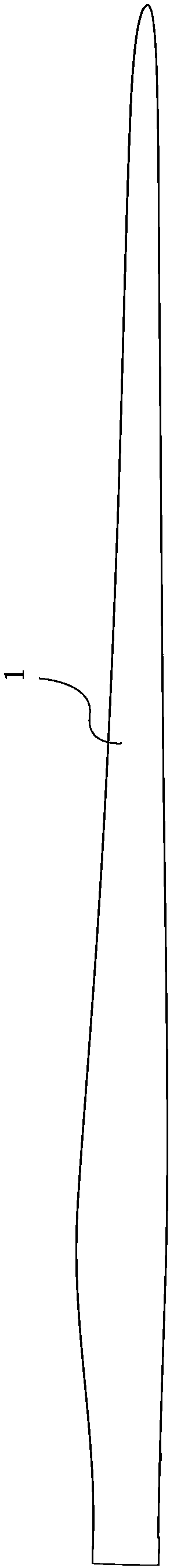

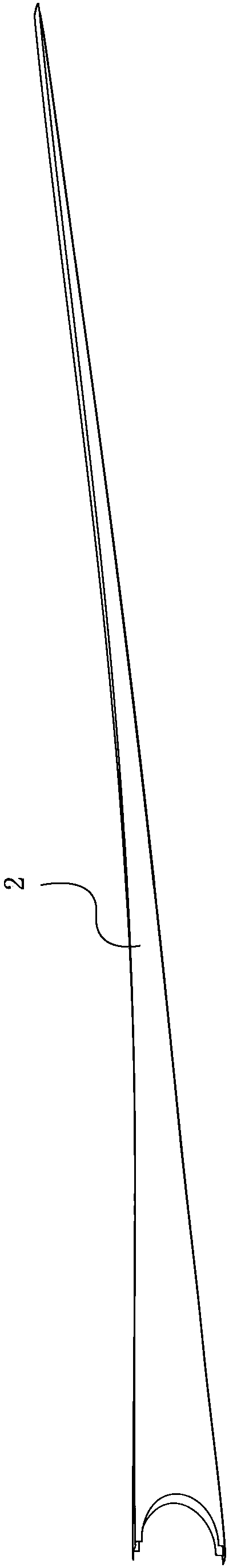

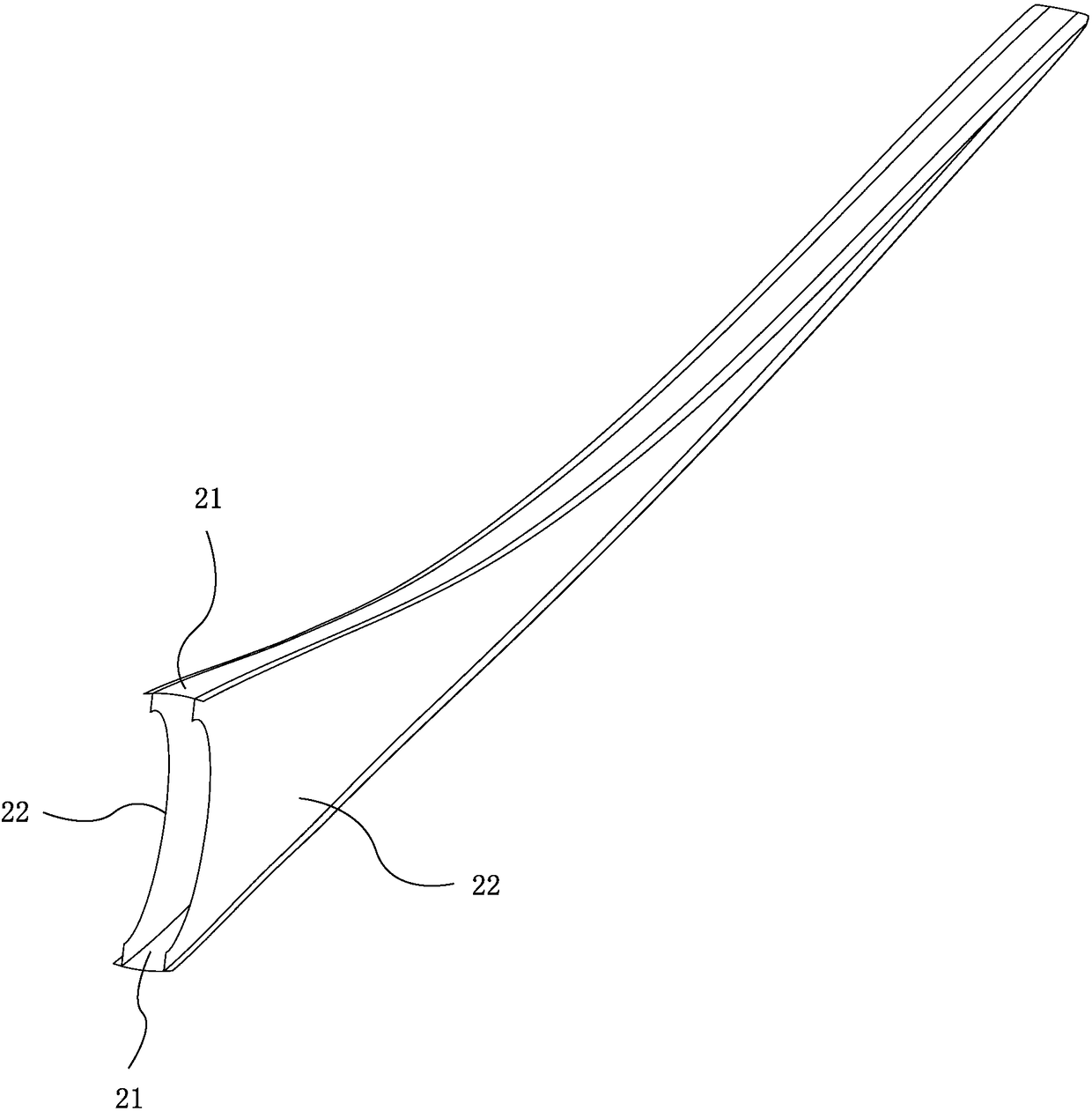

[0037] First, refer to Figure 1 to Figure 3 Describe the shape of a conventional blade. in, figure 1 is a schematic diagram of the shape of a conventional blade, figure 2 is the schematic diagram of the main beam of the blade, image 3 Yes Yes figure 2 Schematic illustration of the blade in the other direction of the main beam.

[0038] Wind turbines can include such figure 1 Blade 1 shown, as figure 1 As shown, the blade 1 becomes thinner from the root to the tip. figure 2 with image 3 The main spar 2 in can be arranged in the blade 1 . The spar 2 may comprise two spar caps 21 and two shear webs 22 . One of the two spar caps 21 may be arranged on the upper shell of the blade 1 and the other of the two spar caps 21 may be arranged on the lower shell of the blade 1 . Two shear webs 22 are used to support the two spar caps 21 on both sides of the two spar caps 21 . Such as image 3As shown, the height of the shear web 22 is getting smaller and smaller, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com