Spiral reinforcement liner transitional piece of Krah pipe

A transition piece, spiral rib technology, applied in the direction of passing elements, pipes/pipe joints/pipes, pipe connection arrangement, etc., can solve the problems of low strength, poor quality, instability, etc., to achieve fast production, simple structure, size stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

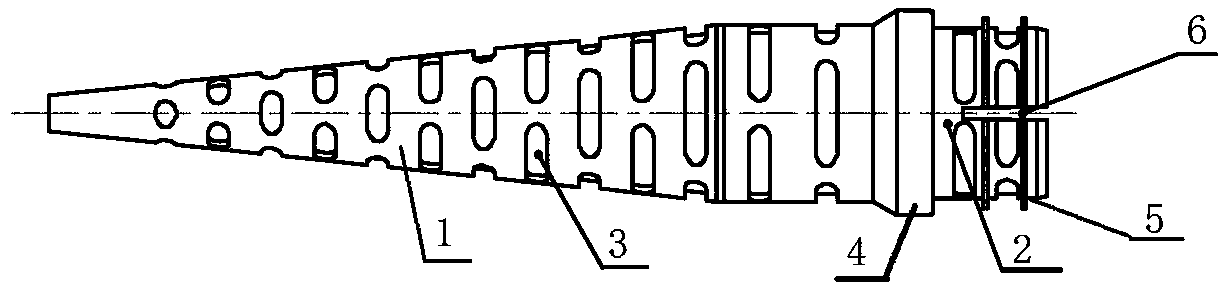

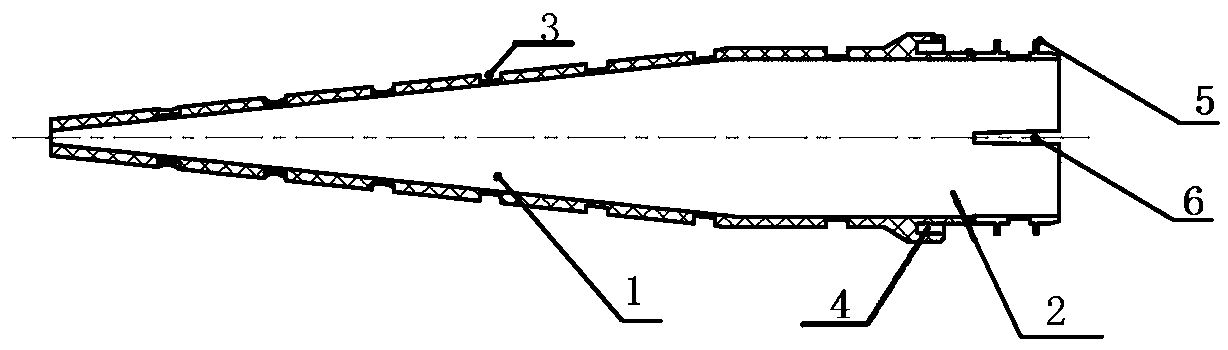

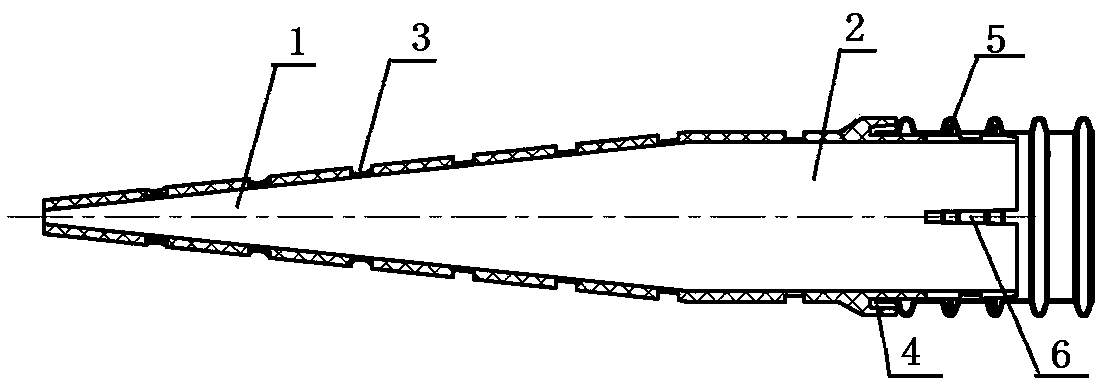

[0023] Such as Figure 1 to Figure 3 As shown, a spiral rib lining transition piece for a carat tube, which includes a vertebral body 1, and the end of the large diameter of the vertebral body 1 is provided with a socket 2, and the socket 2 is an elastic socket, and the outer surface of the transition piece There are clearly staggered blind grooves 3, and the transition piece is connected with the inner bellows at the first and last ends of the spiral ribs on the periphery of the carat tube by means of the socket 2.

[0024] The lining transition piece is composed of a cone 1 and a socket 2. The entire outer surface is provided with staggered and distinct blind grooves 3, and is formed by injection molding, so that the lining transition piece can rotate 360 degrees along the axis. Free bending, high strength; its cone 1 structure can be a reasonable transition from small to large and from large to small for the lining bellows at the first and last ends of the outer spiral ri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap