Live working electric lopper saw

A technology of live working and high-branch sawing, which is applied in the field of electric saws, can solve problems such as difficulty in normal work, inconvenience for customers using electricity, and inapplicability, and achieve the effects of avoiding fire safety hazards, reducing inconvenience and losses, and avoiding the danger of electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

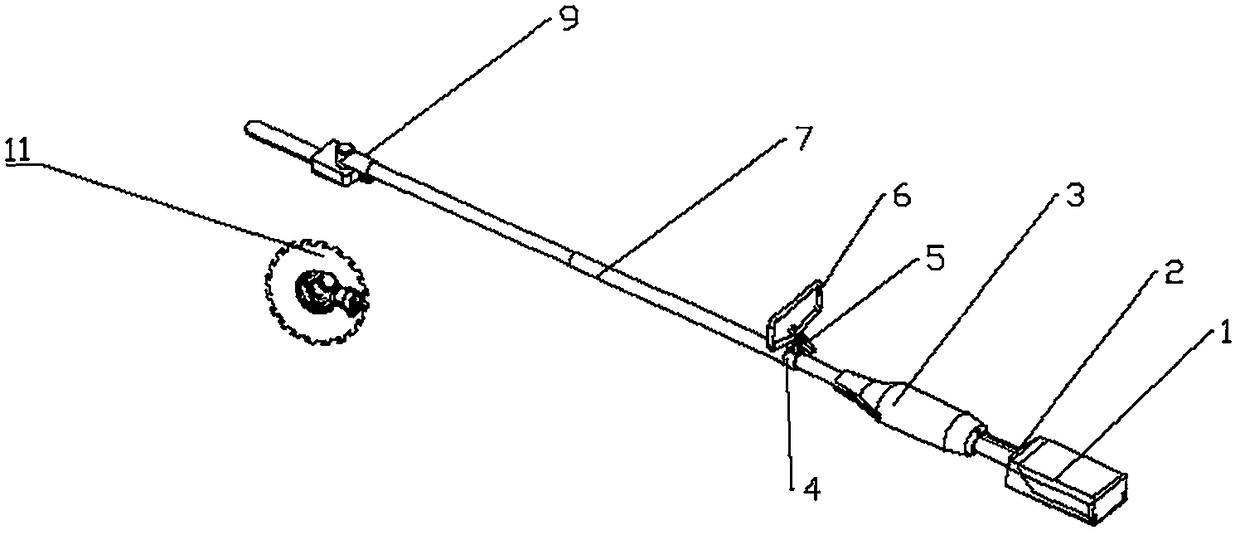

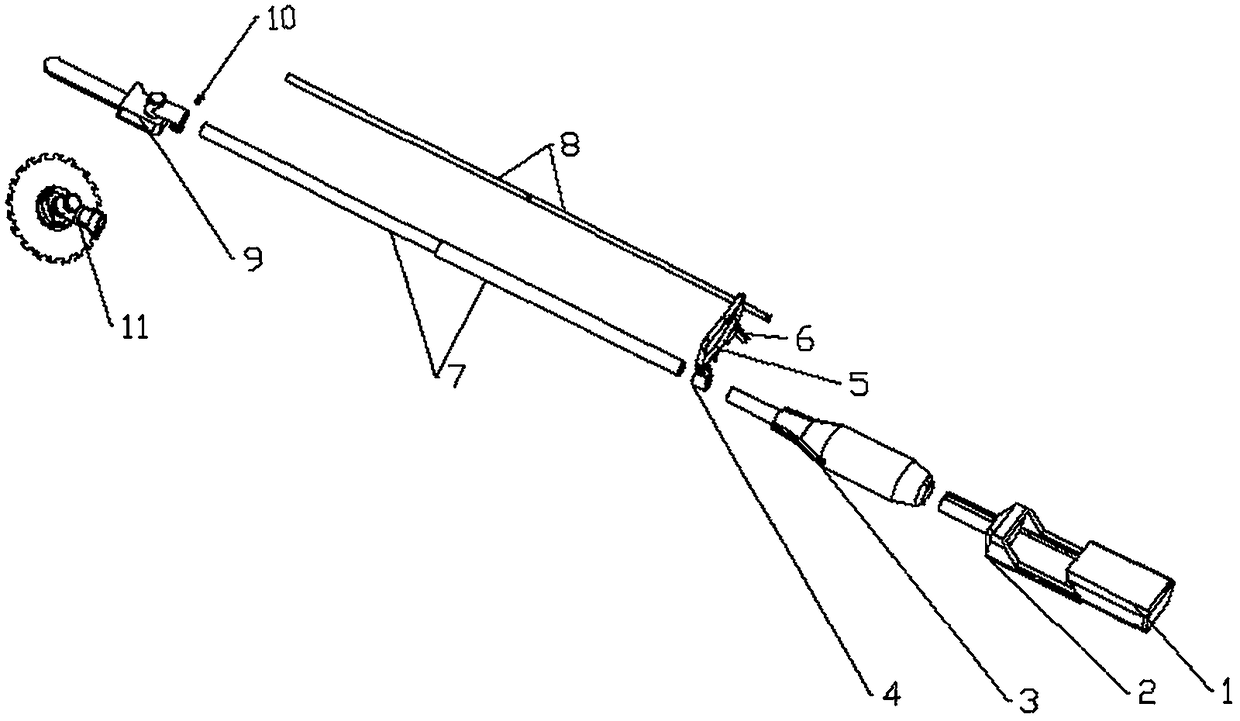

[0031] Embodiment 1. An electric high-branch saw used for live work

[0032] figure 1 , figure 2 The shape and structure of the high-branch saw as a whole and its parts disassembled are shown, respectively.

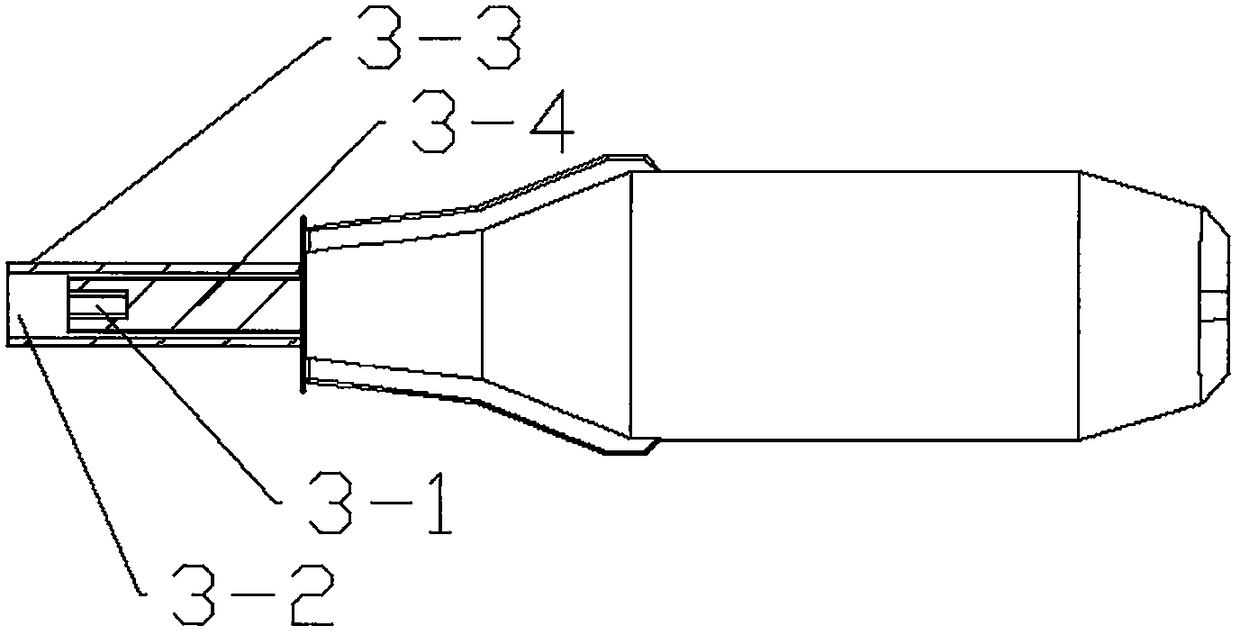

[0033] The rechargeable detachable power supply 1 is a lithium battery, and the power supply 1 is electrically connected to the power supply base 2; a small motor is arranged in the power supply base 2, which converts electric energy into kinetic energy for motor rotation.

[0034] The power supply base 2 is connected to the tail of the gear box 3; the operating rod fixing part 4 is installed on the upper end of the gear box 3, and the handle 5 is connected to the operating rod fixing part 4. A handle bolt 6 passes through the connection hole between the handle 5 and the operating rod fixing part 4 , connecting the handle 5 and the operating rod fixing part 4 as a whole;

[0035] The transmission shaft 8 is placed inside the insulating operating rod 7 (the insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com