Non-woven bag demolding machine

A technology of non-woven bags and demoulding machines, which is applied in bag making operations, paper/cardboard containers, containers, etc., and can solve problems affecting product processing efficiency and yield, complex demoulding device structure, and affecting product follow-up processing, etc. , to achieve the effect of simple structure, long service life, reliable and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

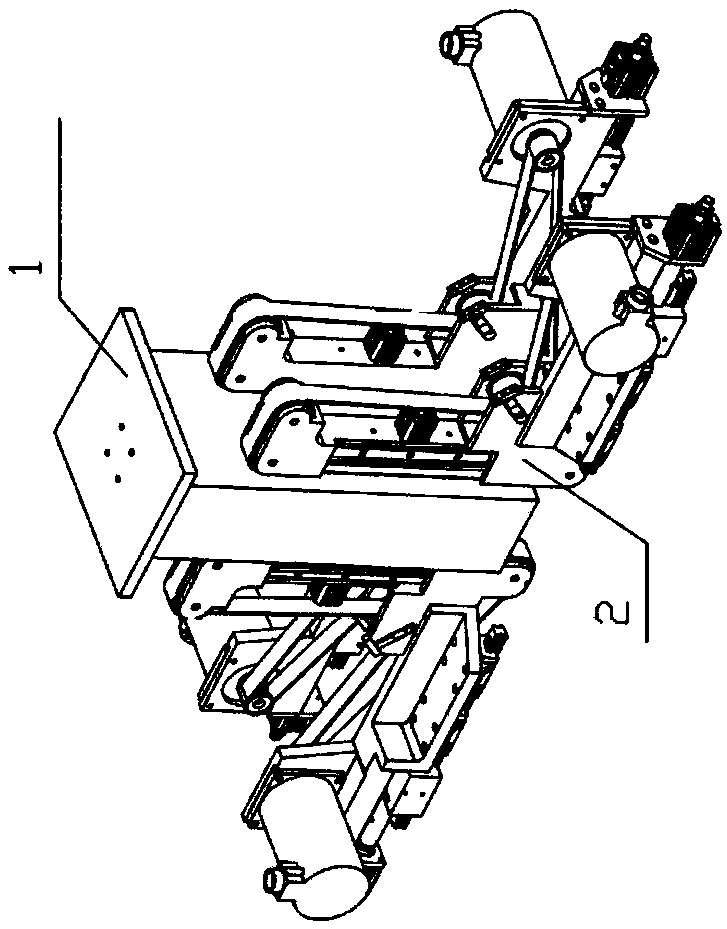

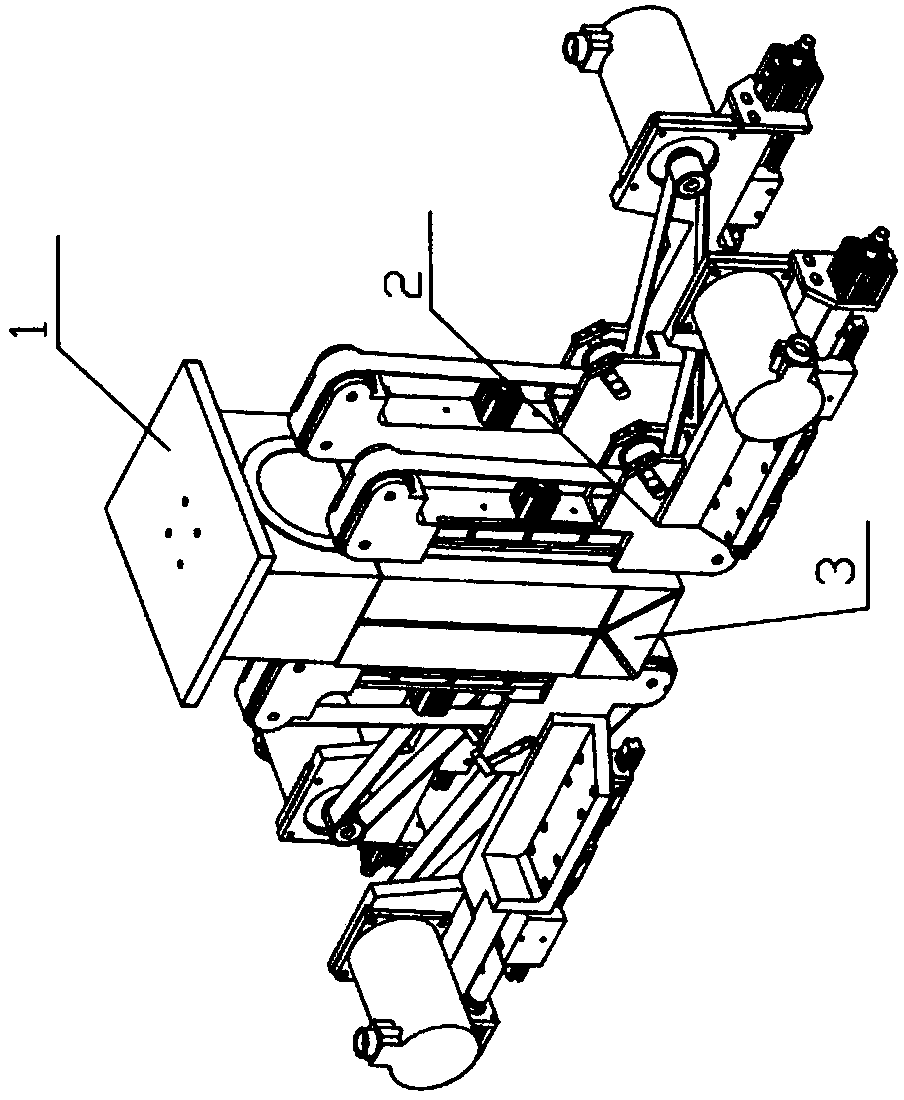

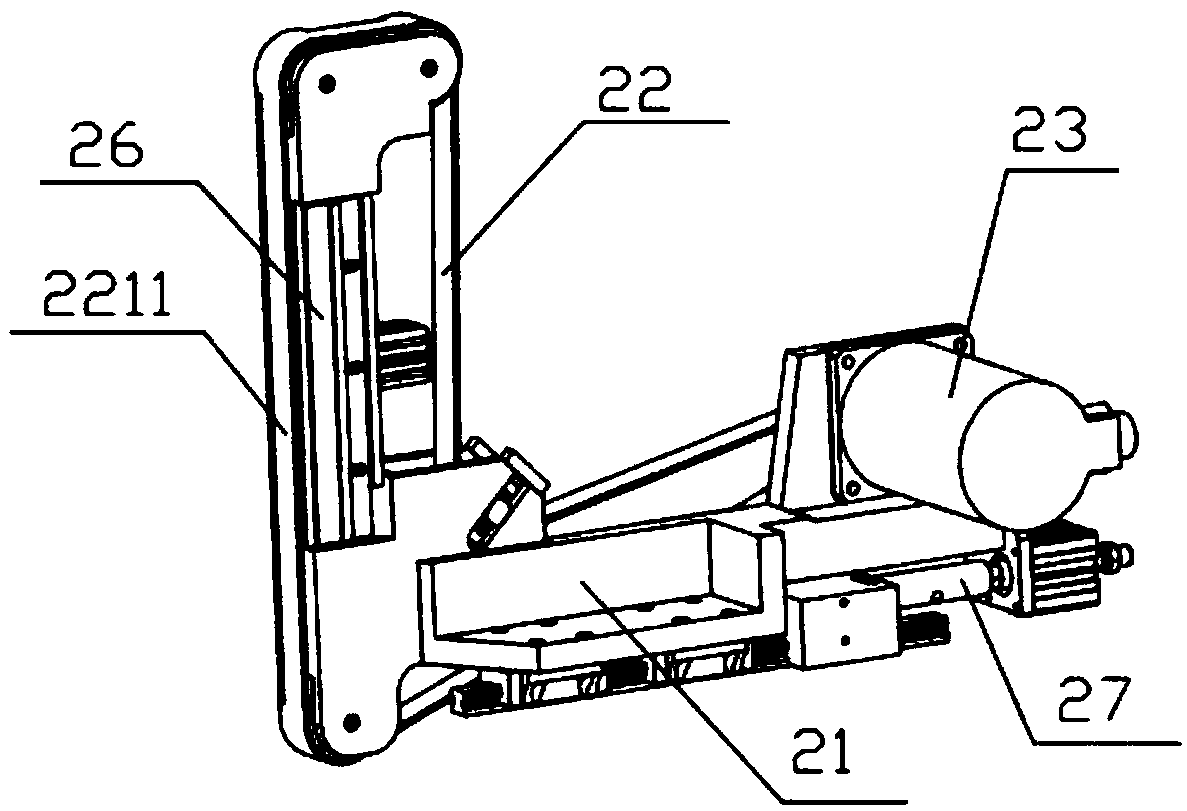

[0021] This embodiment provides a non-woven bag demoulding machine, including a molding die 1 and at least one demoulding mechanism 2, the molding die 1 has a first position when installed and a second position that is convenient for processing bags, so When the mold 1 is in the second position, the demoulding mechanism 2 separates the molded bag from the mold 1. The demoulding mechanism 2 includes a demoulding frame 21, and the demoulding frame 21 is provided with The demoulding part 22 and the demoulding driving part 23 , the demolding part 22 has a first state when installed and a second state where the bag is separated from the forming mold 1 by being driven by the demoulding driving part 23 . The beneficial effect of the present invention is that at least one demoulding mechanism is provided, so that the demoulding mechanism is driven by the demoulding driving part to separate the bag processed and formed on the molding mold from the molding mold when the molding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com