Automatic bidirectional winding and pulling device for sun protection and heat preservation of vegetable greenhouse

A vegetable greenhouse and leak-proof technology, applied in greenhouse cultivation, climate change adaptation, botany equipment and methods, etc., can solve the problems of inconvenience, increase maintenance cost, troublesome operation, etc., and achieve the effect of convenient operation, easy operation and worry-free operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

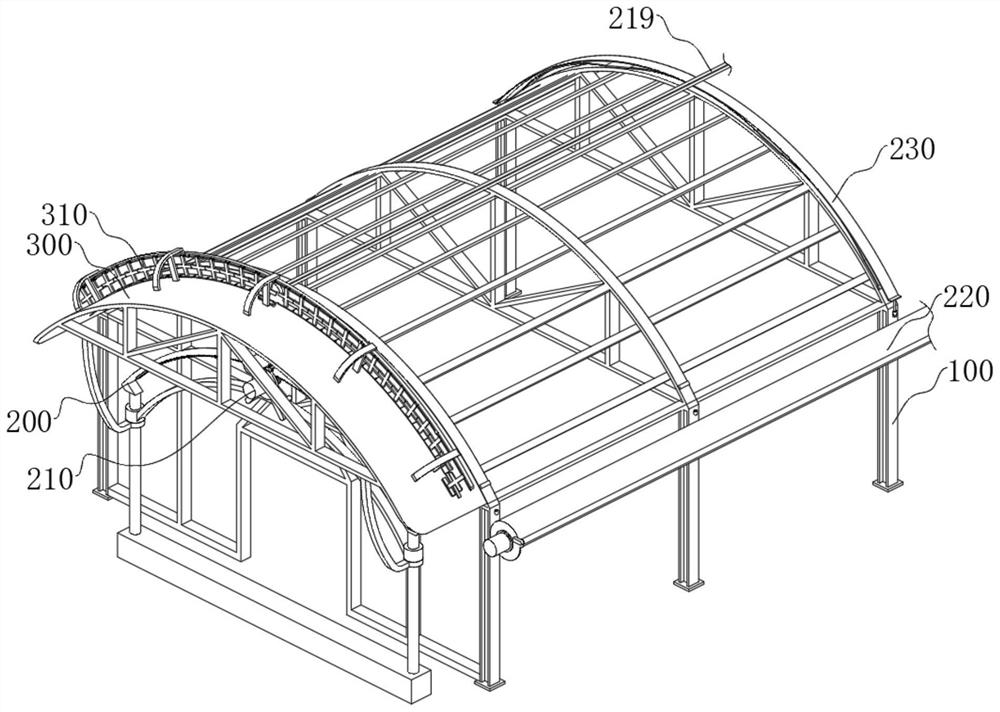

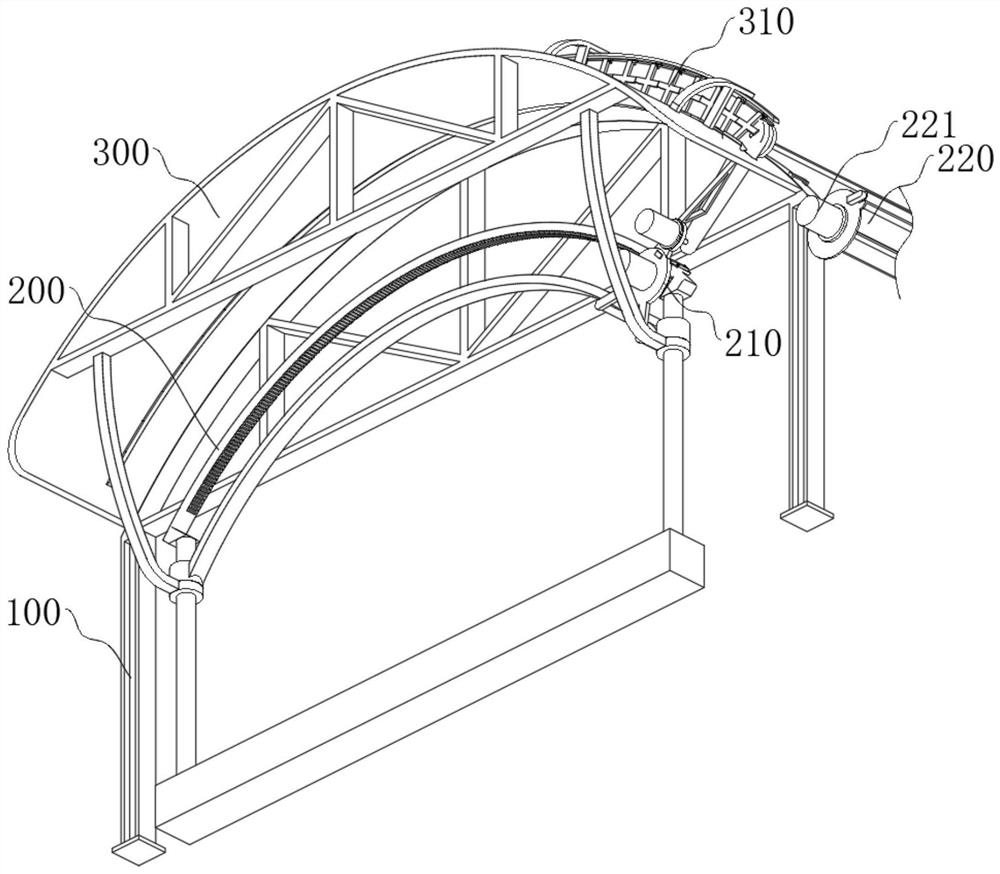

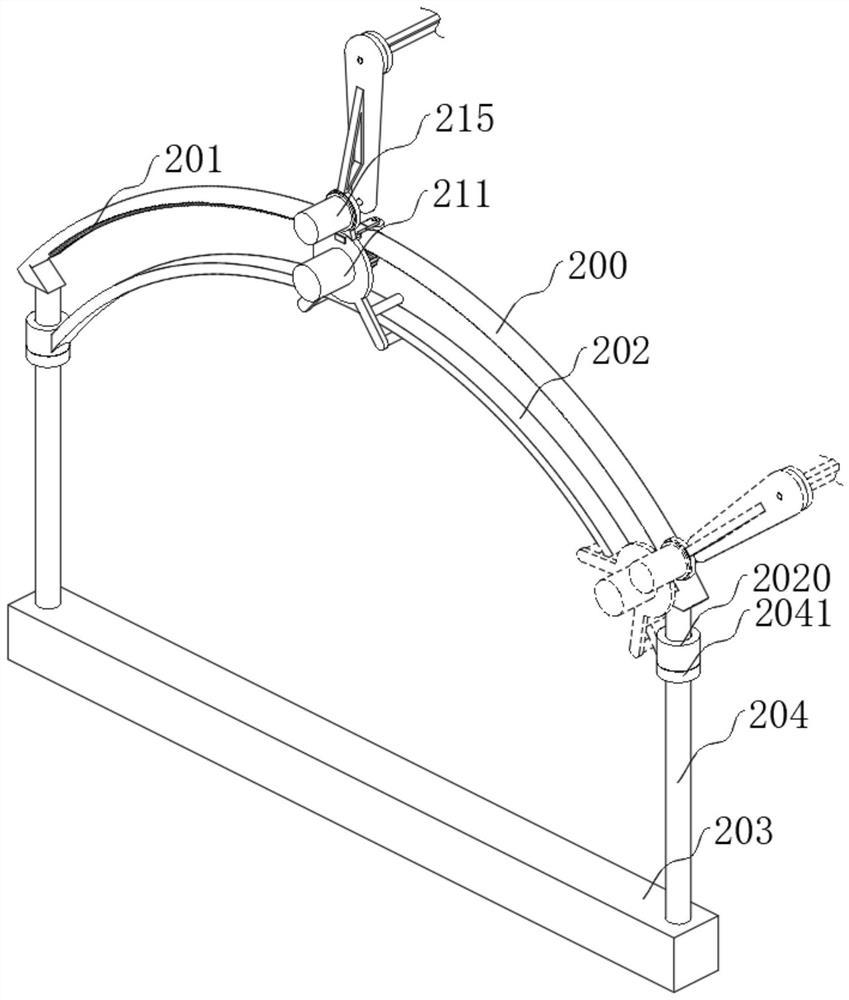

[0044] see Figure 1 to Figure 9 As shown, the present invention provides an automatic two-way rolling device for sun protection and heat preservation in vegetable greenhouses, which includes a greenhouse overall skeleton structure composed of two rows of steel frames 100, and arc beams are installed between the tops of each group of steel frames 100. Plastic film is laid on the arc beams, which can effectively prevent the loss of carbon dioxide produced during the growth of vegetables, so as to achieve the insulation effect required in the greenhouse. A plurality of straight beams are installed at equal intervals inside the plurality of arc beams, which are used to connect the plurality of arc beams into a whole, and strengthen stability. Both ends of the whole steel frame 100 are provided with a winding frame 200 which is coaxial with the arc beam of the steel frame 100, and one side of the winding frame 200 is provided with a winding mechanism 210 which moves along its arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com