Device for wine brewing

A fermentation device and filtration device technology, which is applied in the field of brewing devices, can solve the problems of low production efficiency, poor filtration effect, slow filtration, etc., and achieve the effects of sufficient and uniform fermentation, high utilization rate of raw materials, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

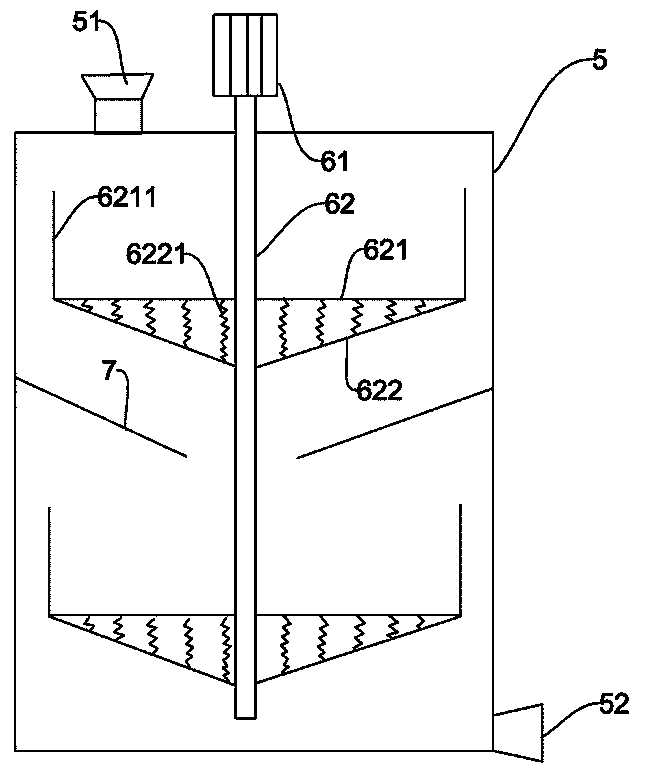

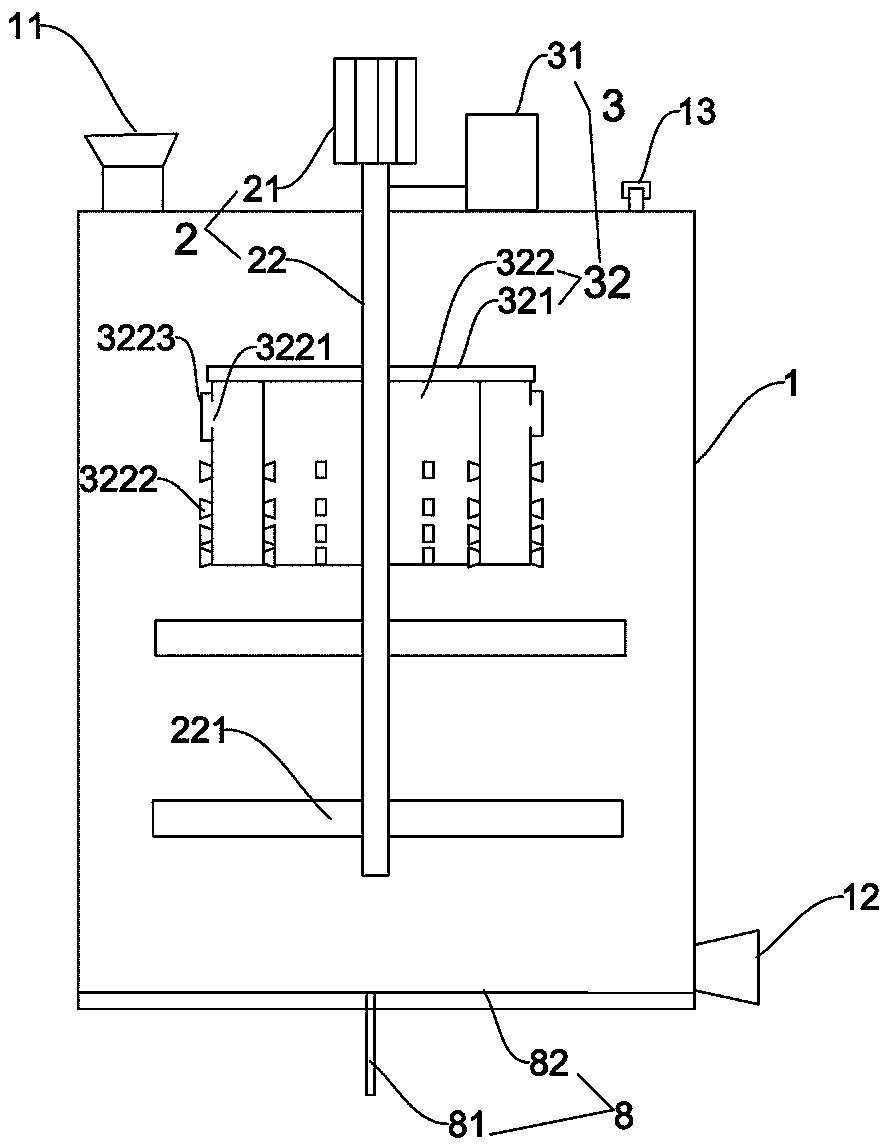

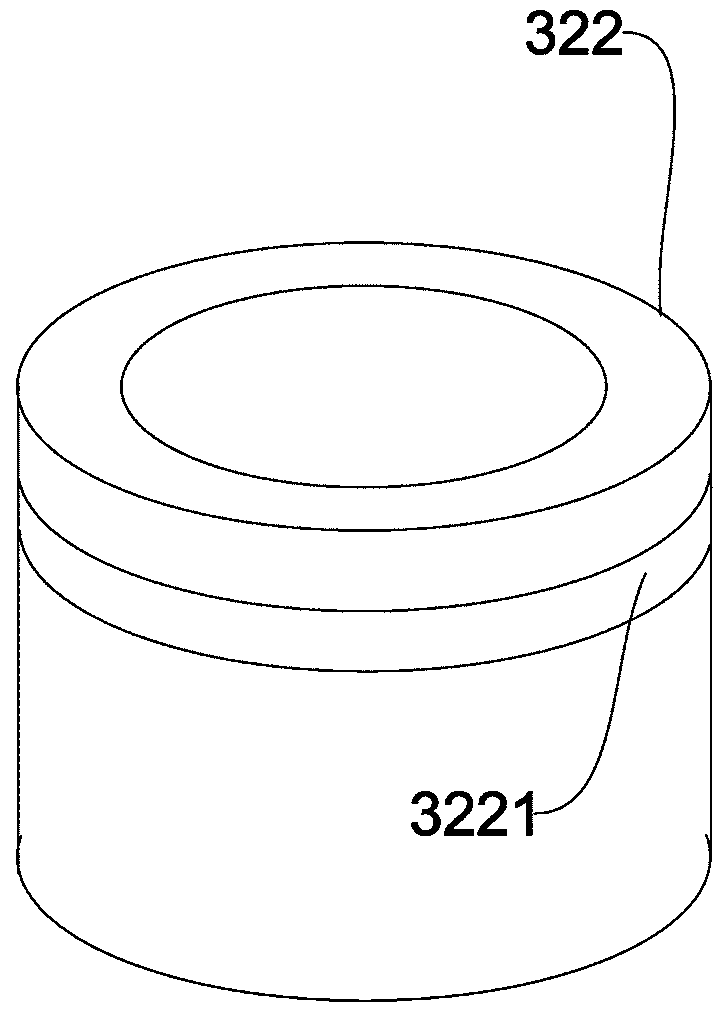

[0025] like Figures 1 to 4 The shown device for brewing wine includes a fermenting device and a filtering device connected with the fermenting device.

[0026] Described filter device comprises filter tank 5 and filter element 6, and described filter element 6 comprises the rotary motor 61 that is arranged on described filter tank 5 top and the rotary shaft 62 that links to each other with described rotary motor 61, and on described rotary shaft 62 A multi-layer filter screen 621 is provided, and the filter screen 621 is bent upward to form a blocking portion 6211. A drain plate 7 is arranged between the filter screens 621. One end of the drain plate 7 is connected to the filter tank 5, and the drain plate 7 is connected to the filter tank 5. The other end of the plate 7 surrounds the rotating shaft 62 and there is a gap with the rotating shaft 62. The drainage plate 7 is provided with a plurality of drainage holes; the upper end of the filter tank 5 is provided with a liquid...

Embodiment 2

[0036] like figure 1 , 3 A kind of brewing device shown in 5 includes a fermenting device and a filtering device connected with the fermenting device. More preferably on the basis of embodiment 1:

[0037] A stirring zone is formed between the spraying part 322 and the stirring shaft 22, and the stirring shaft 22 is provided with a second stirring blade 222 located in the stirring zone. The stirring is more uniform and sufficient, which makes the fermentation more uniform and sufficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com