An inner drum tripod and drum washing machine

A drum washing machine, washing machine technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of difficult flushing water and limited flushing effect, avoid secondary pollution, improve environmental quality, and solve the problem of easy dirt Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

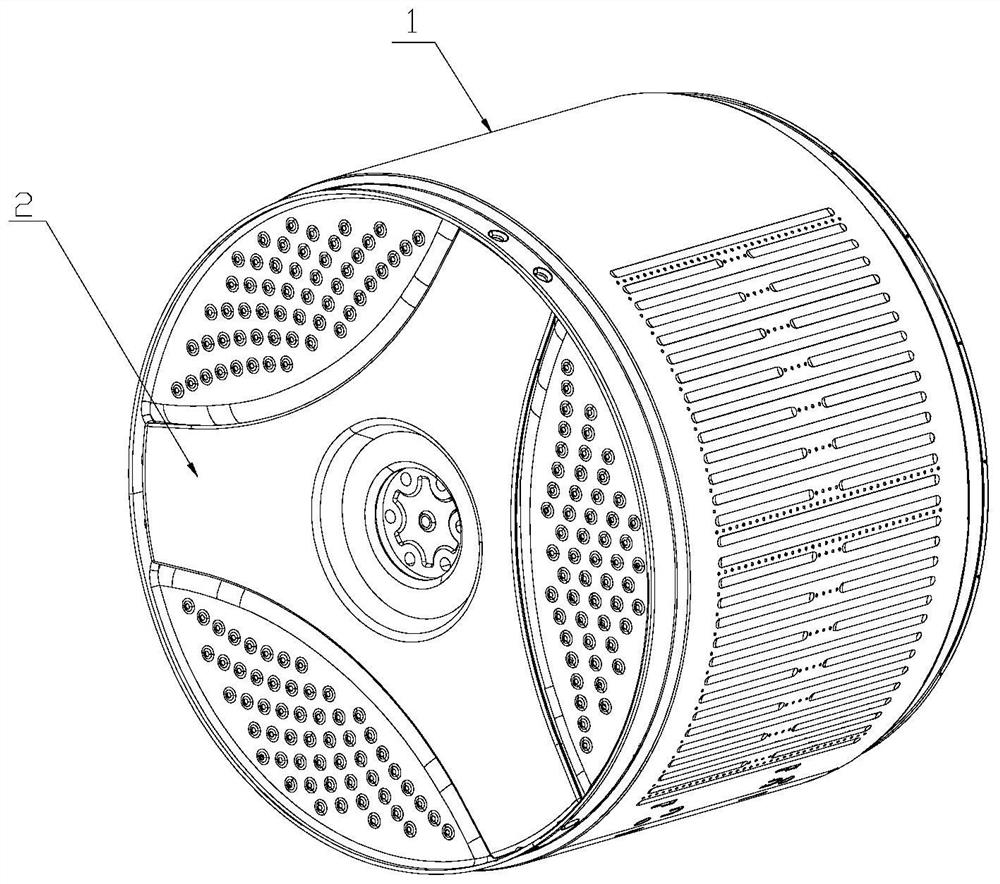

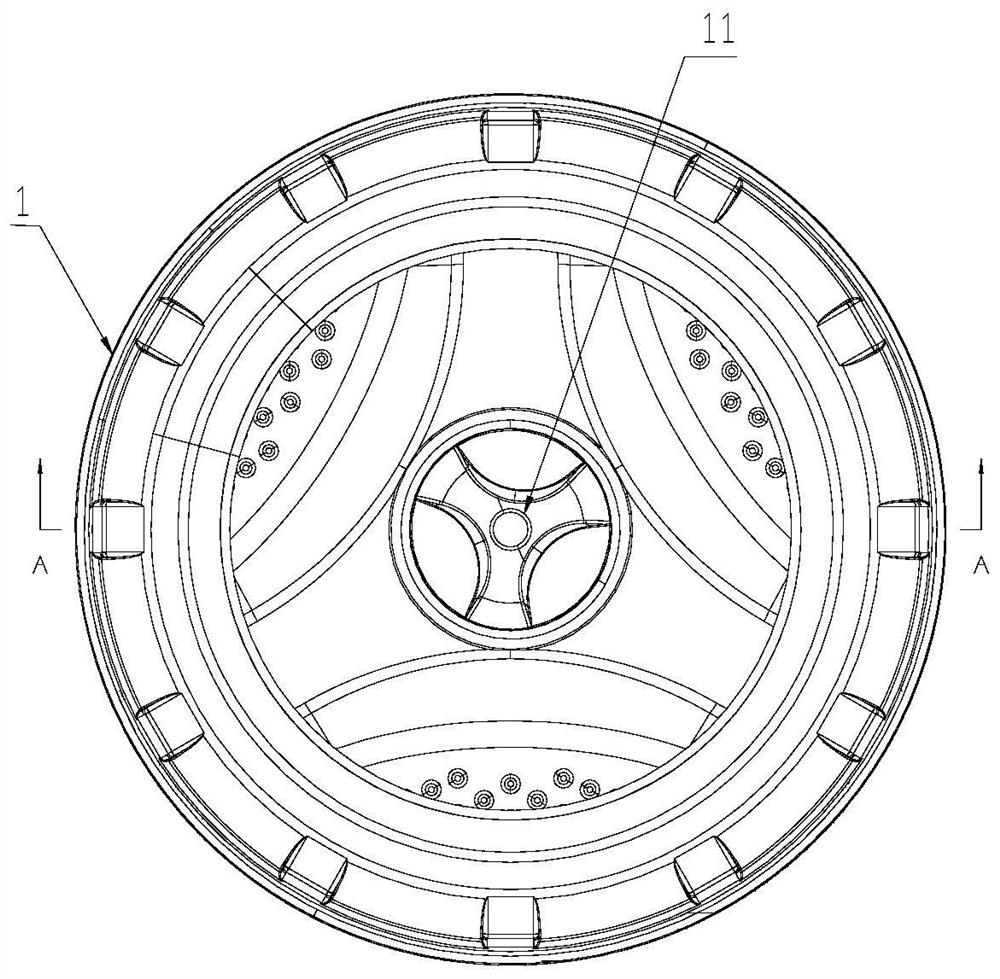

[0030] Such as figure 1 As shown, an inner cylinder tripod is generally installed at the bottom of the inner cylinder 1 of the washing machine to improve the strength of the inner cylinder 1 of the washing machine. Specifically, it includes a body 2 for connecting with the inner cylinder 1 of the washing machine. The body 2 is The triangular structure includes three radially extending support arms, the support arms are distributed at an angle of 120 degrees, and have a certain thickness.

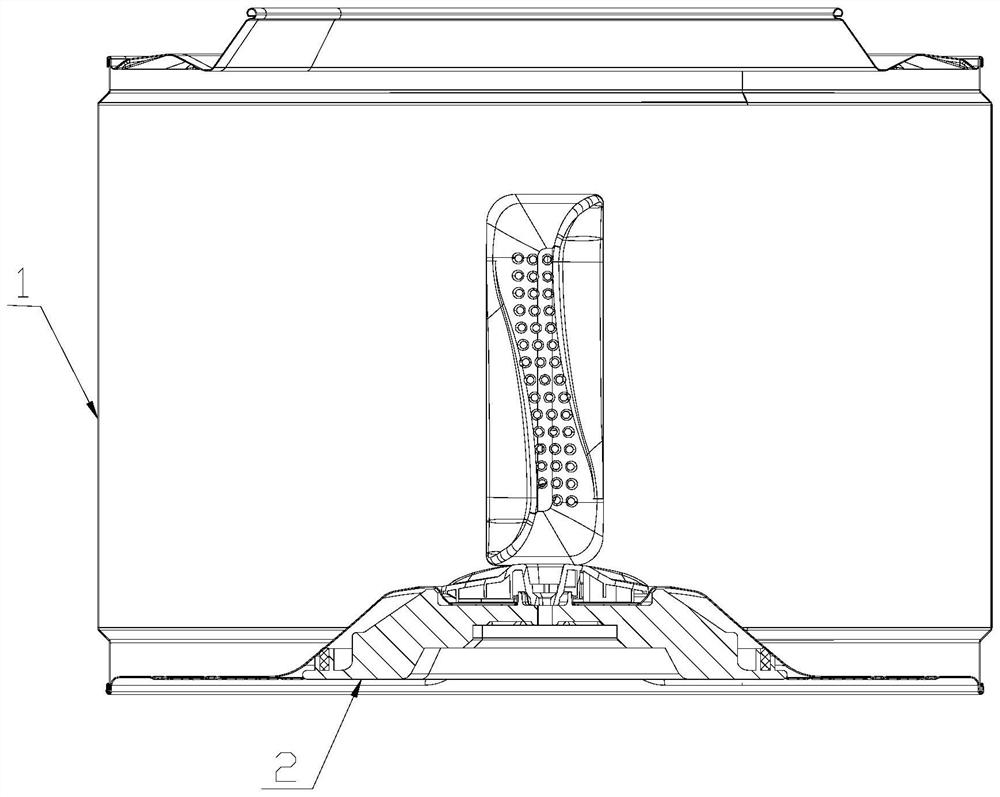

[0031] combine figure 2 with image 3 As shown, one side of the body 2 faces the inner drum 1 of the washing machine, and the other side faces away from the inner drum 1 of the washing machine. After the body 2 is installed on the inner drum 1 of the washing machine, there will be a certain gap between the two. Dirt enters the gap with the washing water, and the part of the body 2 that is in contact with the washing machine inner drum 1 is provided with a raised sealing structure for prev...

Embodiment 2

[0039] combine Figure 7 As shown, in order to achieve a better sealing effect, the installation groove 3 is composed of at least three side-by-side raised strip ribs, and at least two side-by-side installation grooves 3 are formed, and the seal 7 is integrated or split Structure, and correspondingly stuck between the ribs, the seal 7 is higher than the ribs, so as to be in contact with the surface of the washing machine inner cylinder 1 .

[0040] Specifically, when the sealing member 7 is an integral structure, multiple rows of sealing strips with multiple raised installation structures 8 can be selected, and each raised installation structure 8 is correspondingly stuck in one installation groove 3 . When the sealing member 7 is a split structure, a rectangular sealing strip can be installed in each installation groove 3 to form multiple sealing contact surfaces and improve the sealing effect.

[0041] A drum washing machine configured with the inner drum tripod in the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com