Assembling integral type underground structure allowing vulnerable portions of prefabricated columns to be replaced

A technology for underground structures and prefabricated columns, which is applied in underwater structures, infrastructure engineering, water conservancy projects, etc. It can solve the problems that the ends of inner columns are easily damaged, reduce the degree of damage, maintain continuous use, and reduce lateral movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

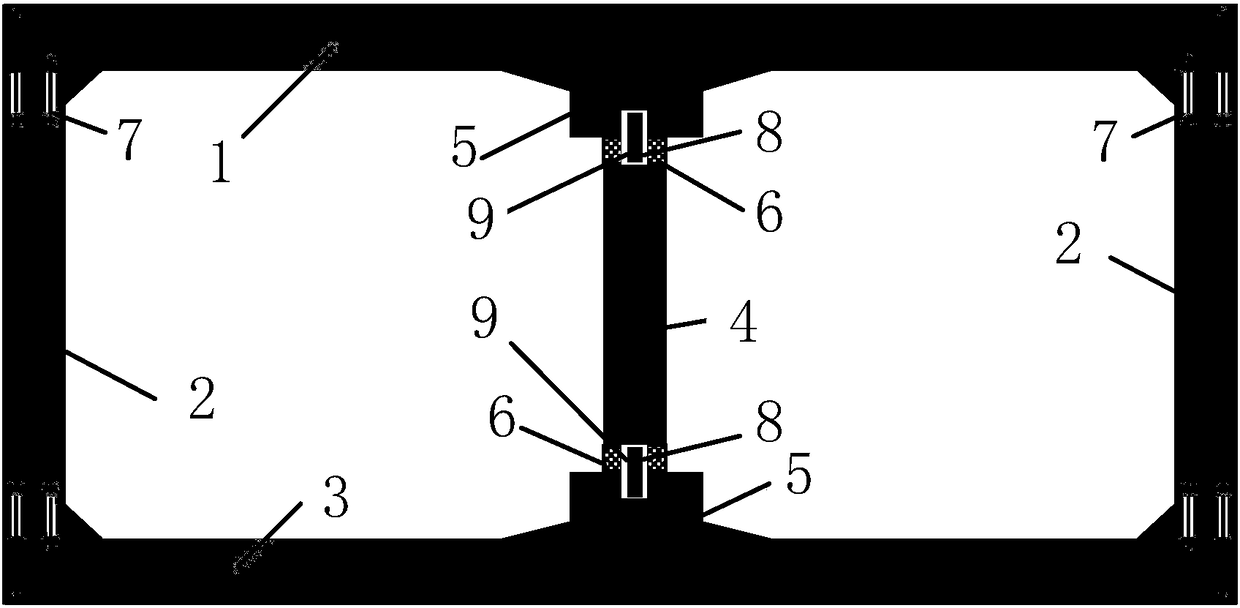

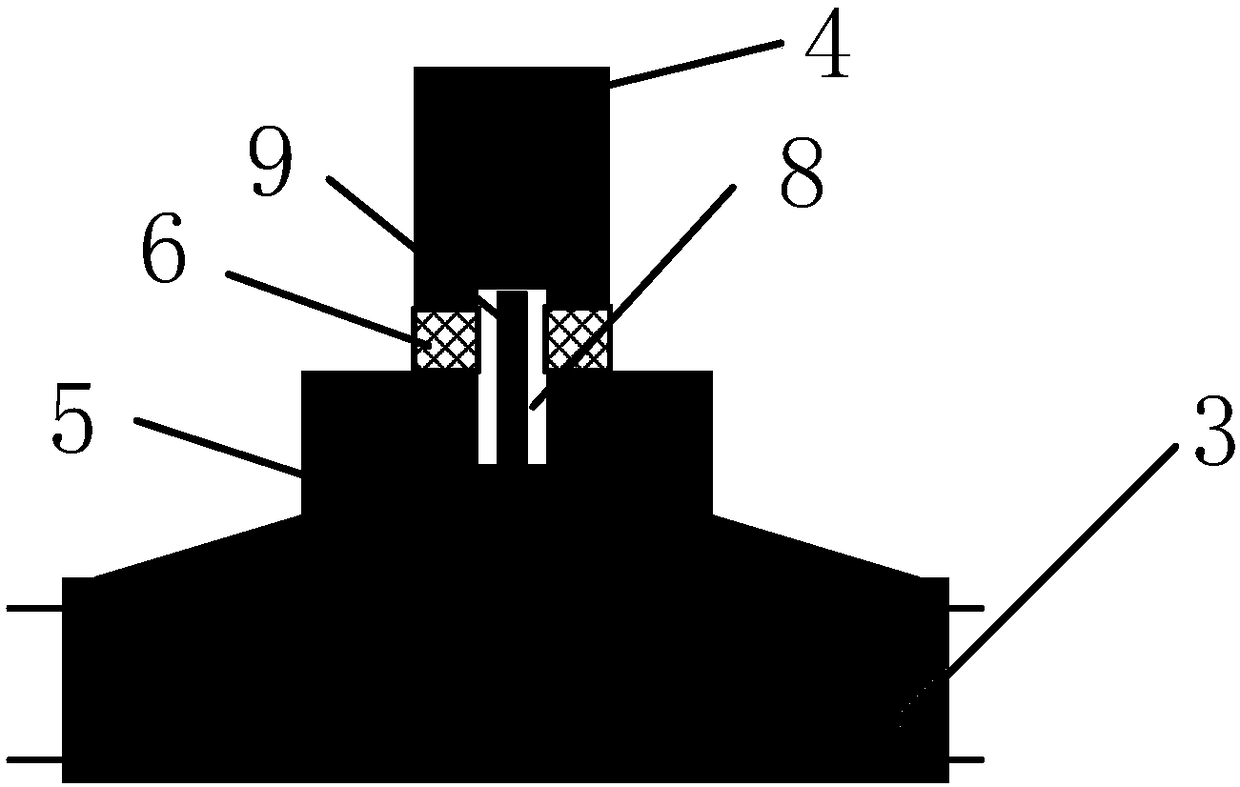

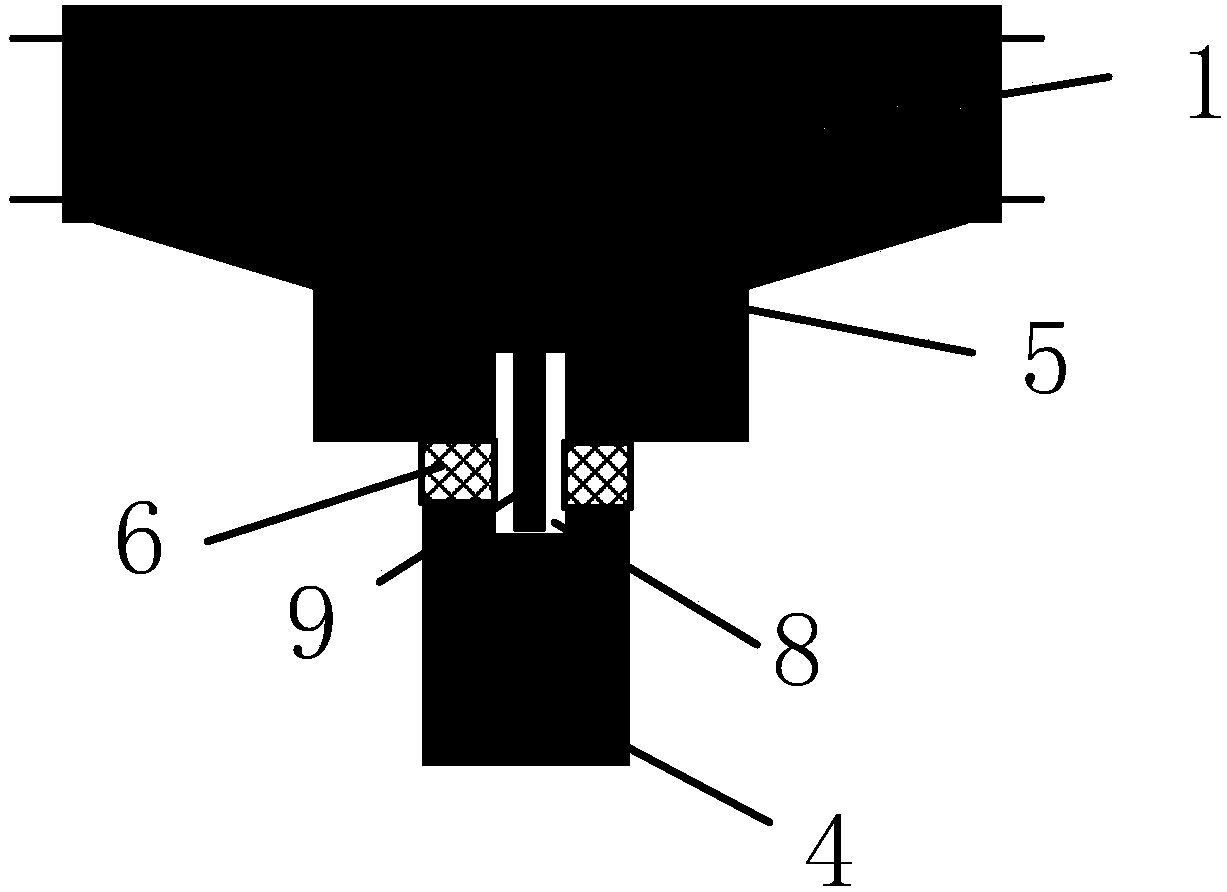

[0015] Below in conjunction with the accompanying drawings, the station roof of the present invention, bottom beam (5) and inner column (4) are connected by shear pin (9), and the inner column end adopts the replacement mode. The specific implementation method is described:

[0016] according to Figure 1-3 , the present invention proposes an assembled monolithic underground structure that can replace the easily damaged parts (6) of prefabricated columns, including: prefabricated roof (1), prefabricated floor (3), prefabricated columns (4), prefabricated beams (5), Shear pin (9).

[0017] Specifically, the prefabricated side walls (2), the prefabricated floor (3), and the prefabricated roof (1) are rationally optimized, and the connection positions are connected by grouting sleeves (7) to ensure rigid connection at the connection positions. The prefabricated top and bottom beams (5) and the prefabricated columns are provided with pin holes (8), and replaceable parts are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com