Lock connecting rod

A connecting rod and connecting lock technology, applied in handle connection, building locks, door/window accessories, etc., can solve problems such as increasing work difficulty, installing parts in place, and connecting hands and lock bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

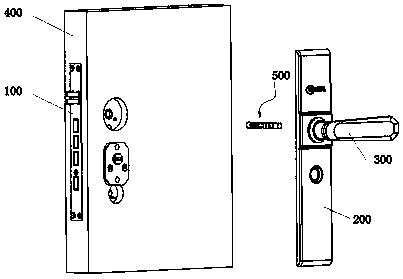

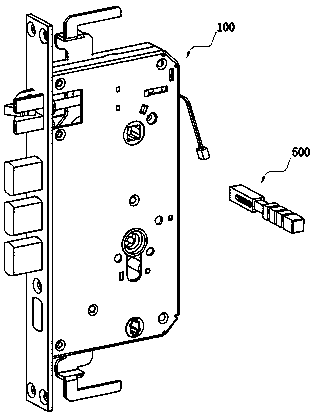

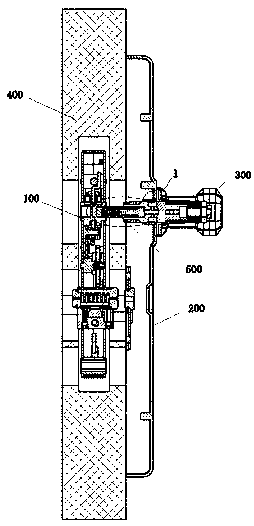

[0026] As attached figure 1 And figure 2 The door lock shown includes a lock body 100, a panel 200, and a handle 300. The lock body 100 is installed in the door panel 400, the panel 200 is installed on the outside of the door panel 400, the handle 300 is installed on the panel 200, and the handle 300 It is linked to the lock body 100 through a connecting rod 500.

[0027] The connecting rod 500 includes a first connecting rod 1, a second connecting rod 2 and an elastic member 3. The first end of the first connecting rod 1 is fixedly connected to the lock body 100 in the circumferential direction (generally, the first end of the first connecting rod 1 is made into a square shape, and the lock body 100 correspondingly has a square hole. The connecting rod 1 is directly inserted into the square hole to achieve circumferential fixation), the first end of the second connecting rod 2 is fixedly connected to the handle 300 in the circumferential direction, and the second end of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com