Crane beam and preparation method and application method thereof

A technology of traveling beams and connecting plates, applied in the directions of load suspension components, rail systems, transportation and packaging, etc., can solve the problems of insufficient support performance, great influence on weld quality, frequent vibration loads, etc., and achieve on-site construction operations. Convenience, saving installation program, simple structure setting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

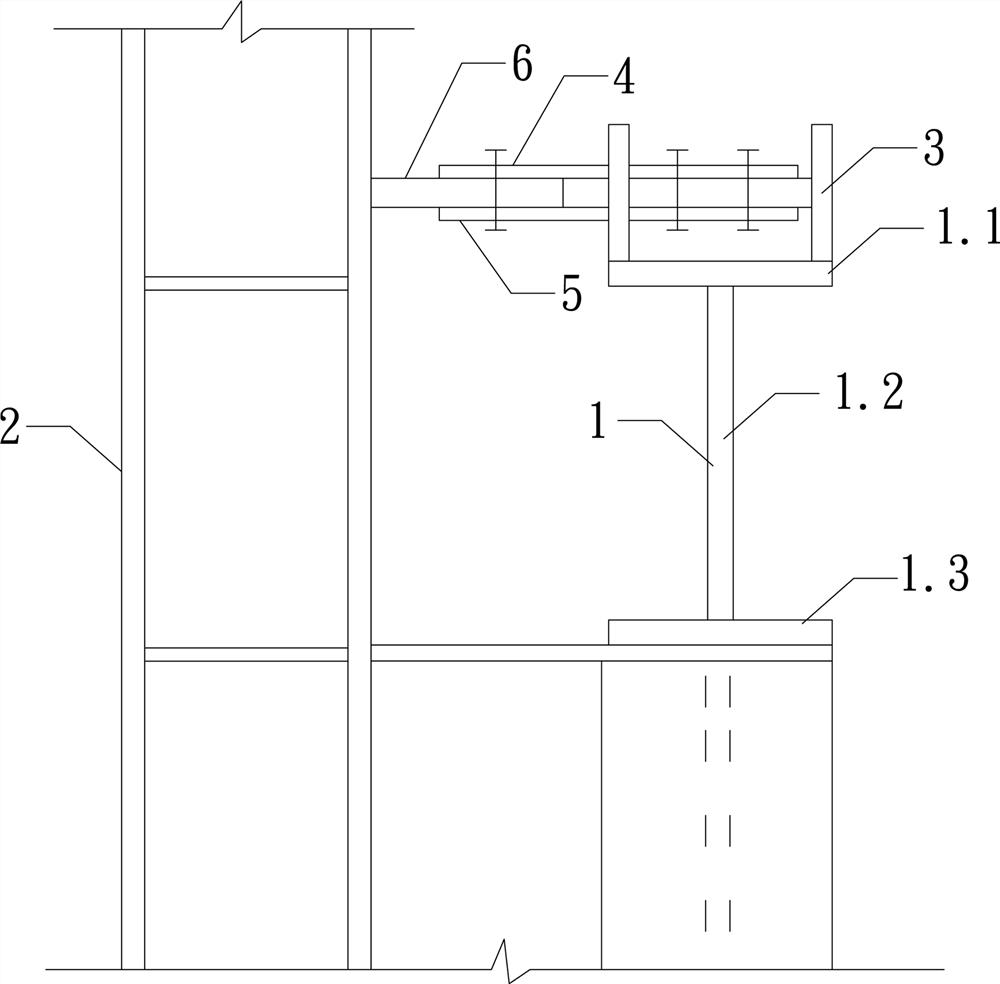

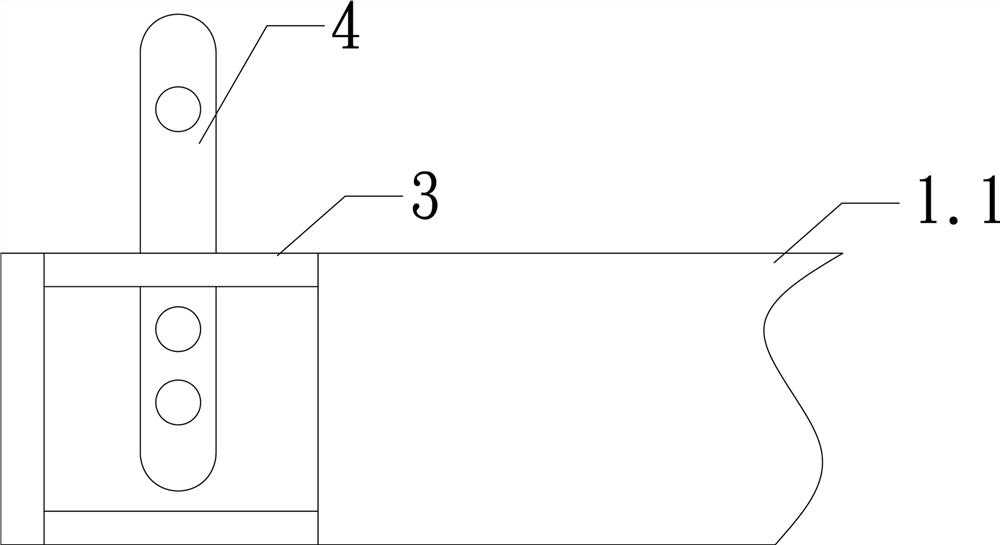

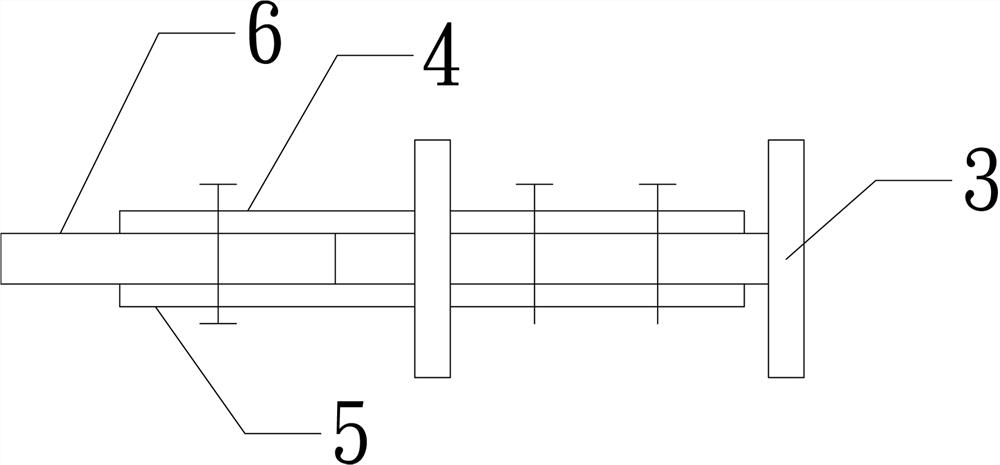

[0031] Such as Figure 1-3 As shown, the driving beam includes a driving beam body 1, a driving beam end mounting frame 2, an end I-beam 3, a connecting plate A4, a connecting plate B5 and a connecting plate C6, and the two ends of the driving beam body 1 Respectively supported on the corresponding driving beam end mounting frame 2, the driving beam end mounting frame 2 includes a vertical column 2.1, and the top of the vertical column 2.1 has a horizontally arranged corbel support 2.2, and the driving beam end The end of the body 1 is supported on the corbel support 2.2, and the upper surfaces of the two ends of the driving beam body 1 are respectively welded with an end I-beam 3, and a connecting plate is detachably installed on the end I-beam 3 A4 and the connecting plate B5, the top of the vertical column 2.1 has a connecting plate C6 connected with the connecting plate A4 and the connecting plate B5.

[0032] In this embodiment, the driving beam body 1 includes an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com