Automatic measurement pin for tension

An automatic measurement and tension technology, applied in the direction of tension measurement, bolts, etc., can solve the problems of inconvenient use, expensive imported instruments, and inaccurate cable measurement, so as to improve the accuracy of measurement, reduce installation procedures and signal loss, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

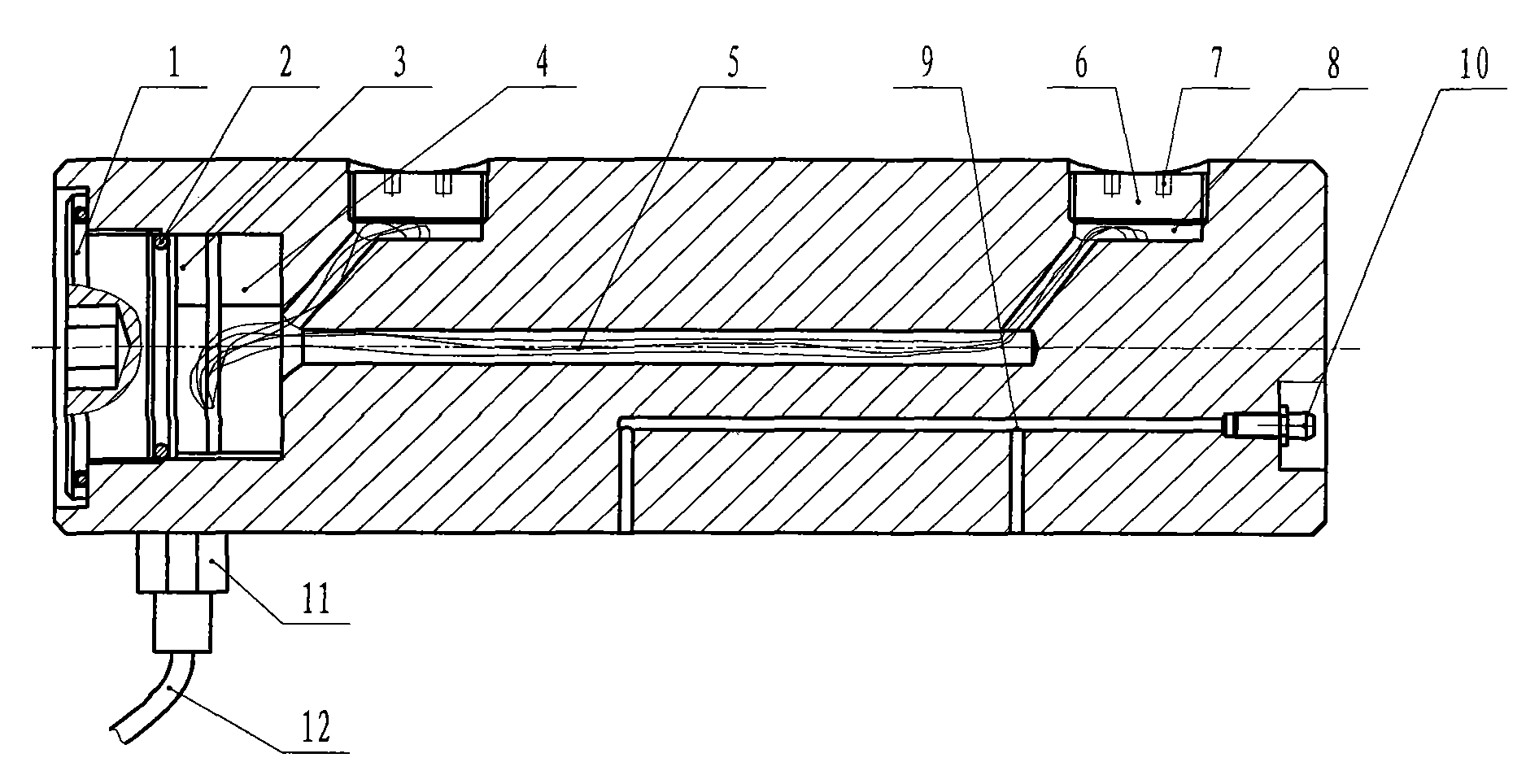

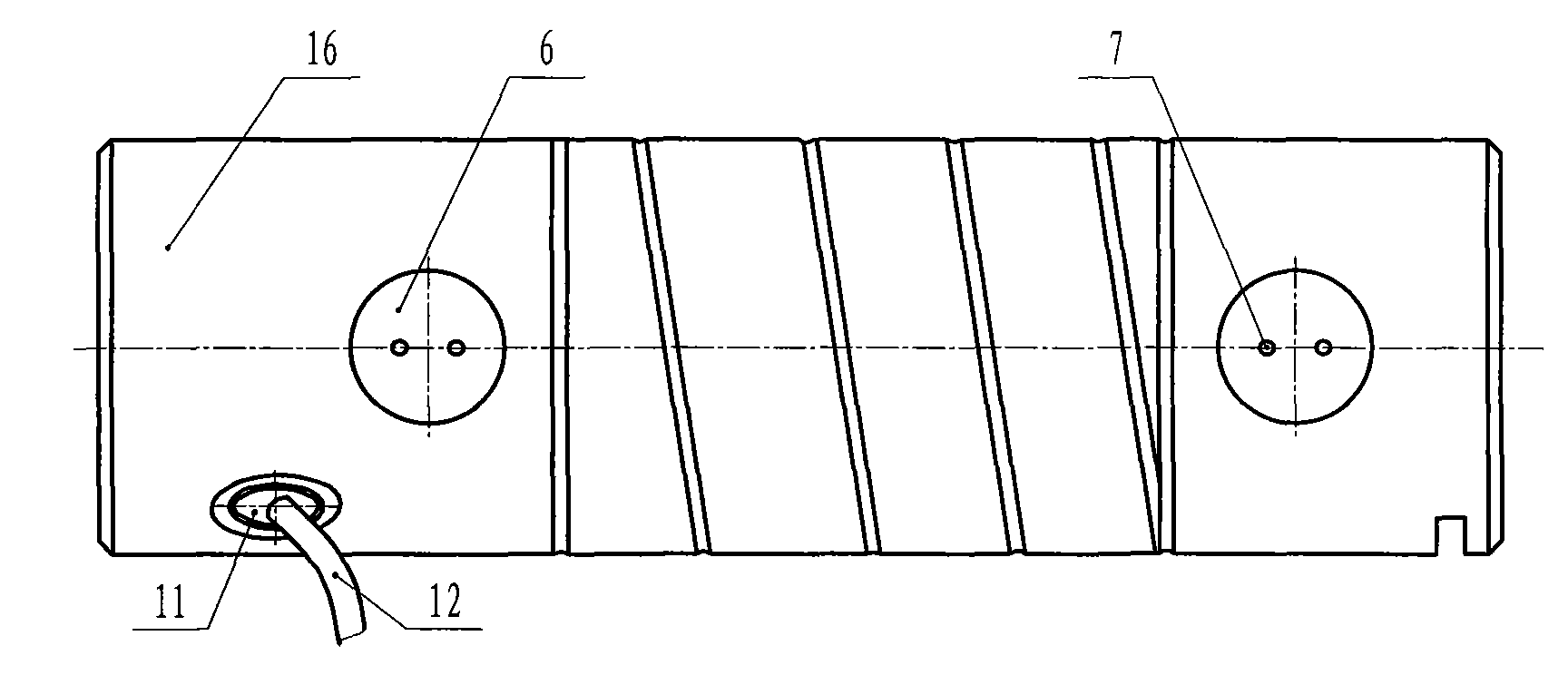

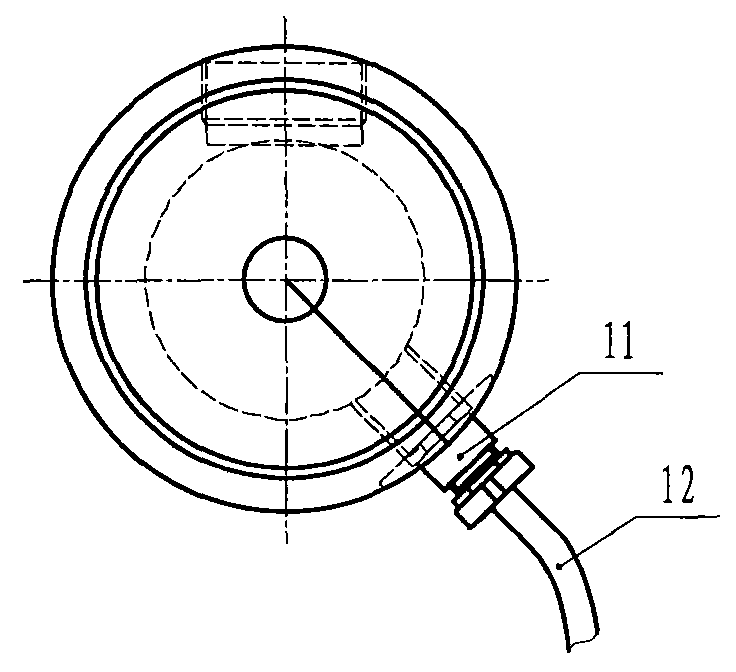

[0015] In the figure, 1. Shaft end cover; 2. Seal ring; 3. Insulation backing plate; 4. Electric signal amplifier; 5. Signal wire; 6. Stress plate; 7. Plug; 8. Sealant; 9. Lubricating oil tank; 10, lubricating oil cup; 11, cable sealing joint; 12, signal cable head; 13, first fixed side plate; 14, tension bushing; 15, second fixed side plate; 16 shaft body.

[0016] An automatic tension measuring pin, including a shaft body 16, an electric signal amplifier 4, a lubricating oil tank 9 and a lubricating oil cup 10 are arranged inside the shaft body 16, two stress plates 6 are arranged on the surface layer, and a cable sealing joint 11 and a signal seal are arranged on the outer wall The cable head 12; the signal cable head 12 is set on the cable sealing joint 11, the electric signal amplifier 4, the stress plate 6 and the cable sealing joint 11 are connected through the signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com