Hanger for hanging laying cable

A technology for laying cables and spreaders, which is applied in the direction of cable installation, cable installation devices, electrical components, etc. It can solve the problems that spreaders and suspension methods cannot be adapted, and achieve shortened installation procedures and installation time, reliable fastening, The effect of large lifting capacity of the spreader

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

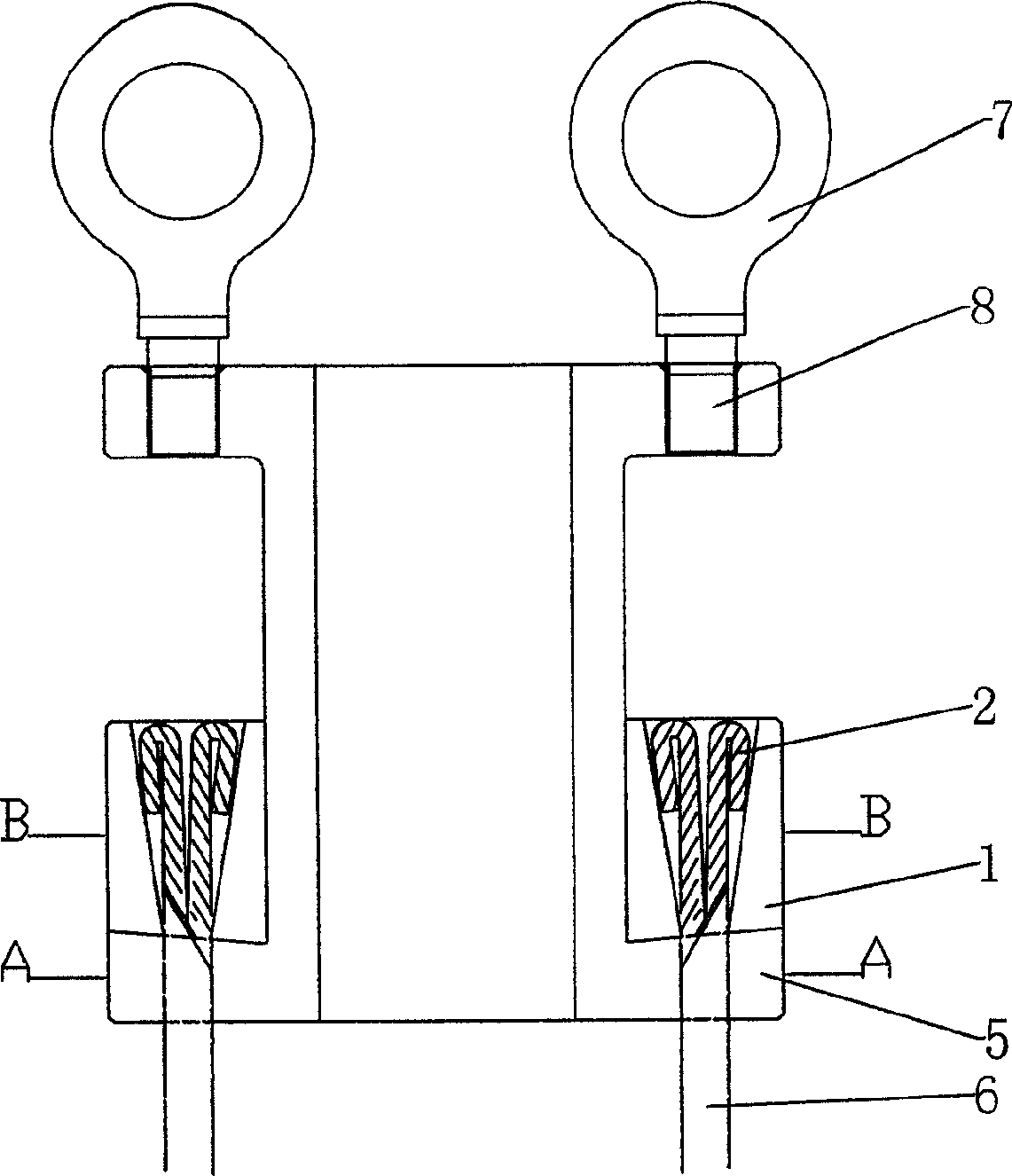

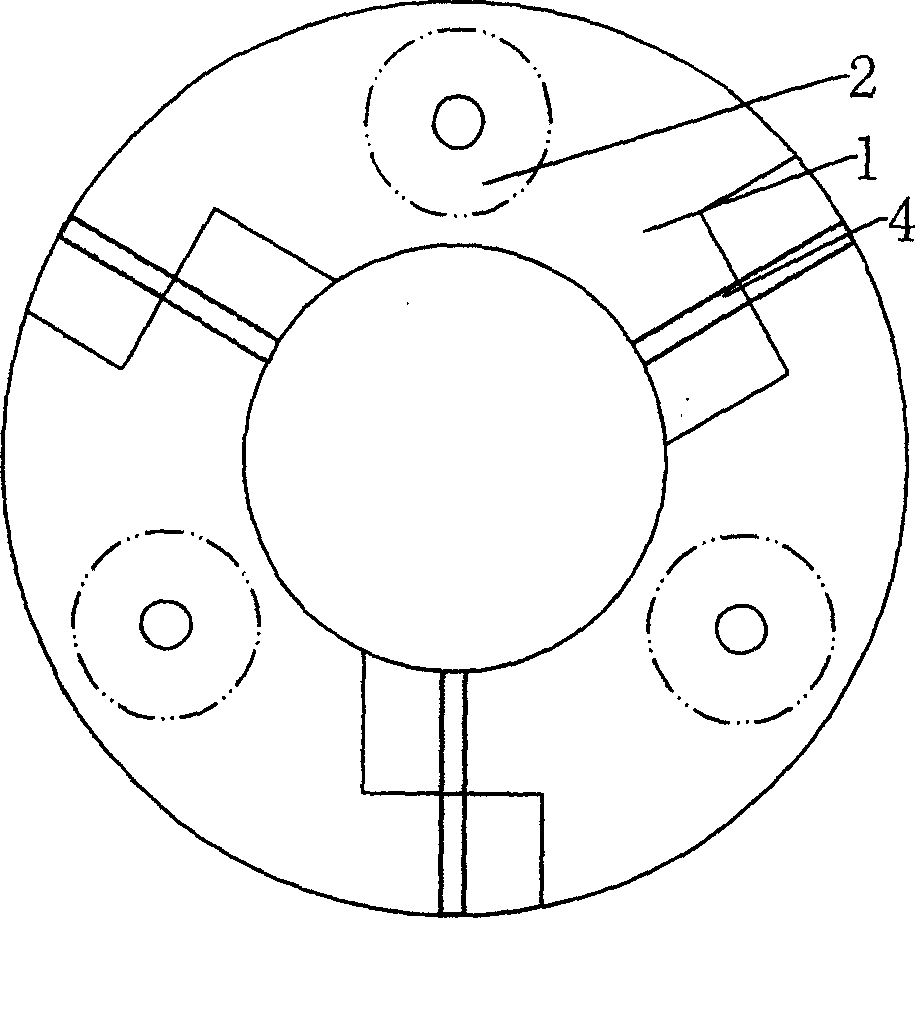

[0021] Embodiment 1: see figure 1 , the vertical laying cable spreader of the present invention includes a "worker" shape reel 8, a plurality of hooks 7 are evenly distributed on the upper face, and the lower face has a chassis 5 and a decomposed and combined disc 1 that is spliced and fixed with steel wires. Composition, in which the superimposed surface of the upper and lower layers is a slope inclined towards the center. The upper plate surface, the chassis surface and the central column are integrated, and the central column is a hollow body. There are U-shaped positioning gaps 11 ( Figure 5 ), the decomposed and combined disk 1 of the fixed steel wire is thicker, and the number of combined pieces is the same as the number of steel wire ropes ( image 3 ), the splicing surfaces of adjacent pieces are complemented in a "Z" shape, and are combined into a whole by bolts 4, and each piece has an inverted tapered fixed wire rope through hole 2 ( Figure 4 ), the cable han...

Embodiment 2

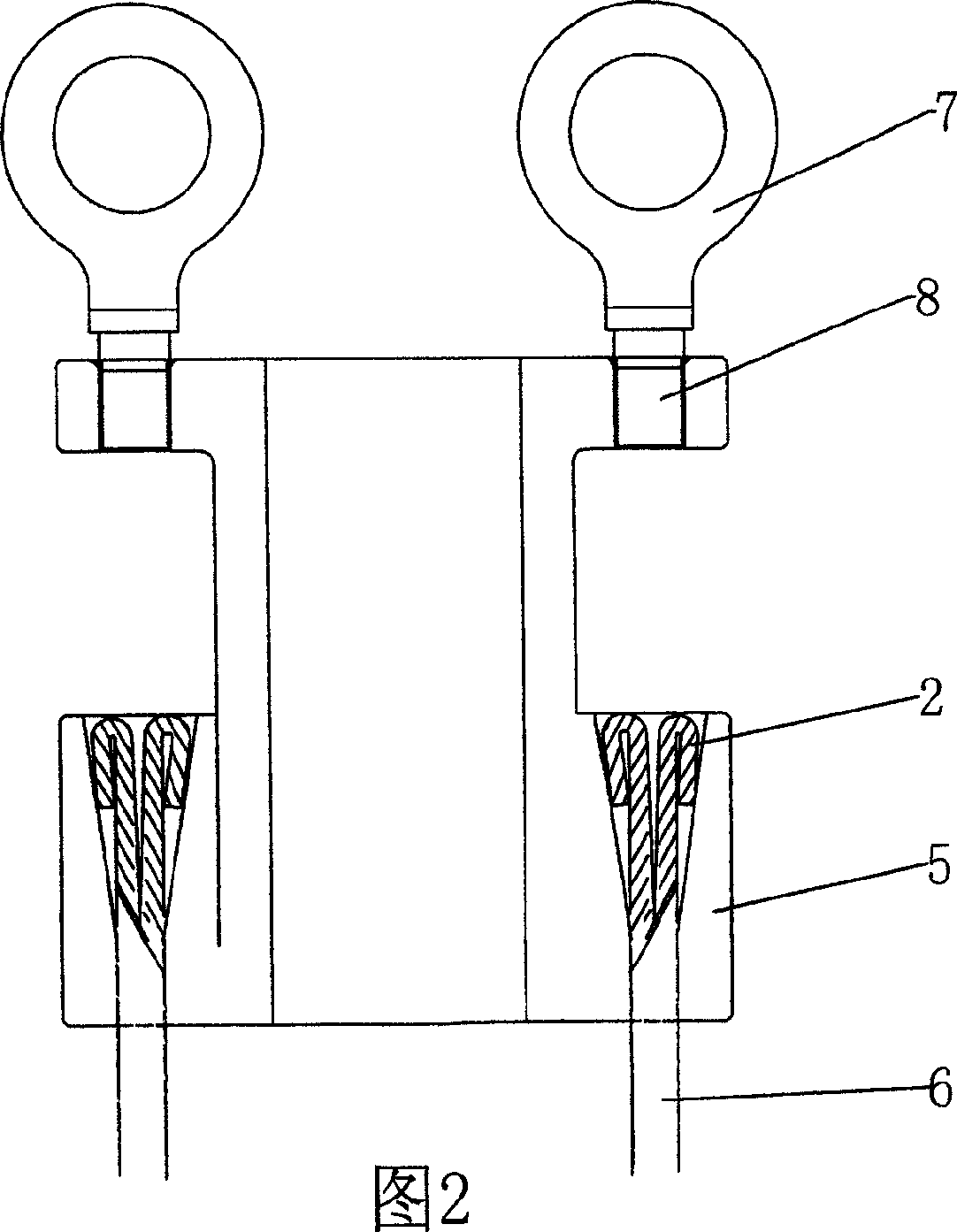

[0022] Embodiment 2: Referring to Fig. 2, as mentioned above, the lower plate and the fixed wire rope drum 5 are of the same single-deck structure, and an inverted tapered hole 2 for fixing the wire rope is opened on it, and the cable supporting wire 6 is fixed in the inverted tapered hole.

[0023] When the cable is hoisted, the sling and the upper cable fixed on it are lifted to the fixed point of the cable shaft 3 through the hook 7, and then the splint 9 ( Image 6 , 7 ), the hanger is placed on the steel beam 13 on the cable well, and then the shelf and the steel beam are fixed with set screws 10.

Embodiment 3

[0024] Embodiment 3: As mentioned above, the hanger can also be an axially split body, which is especially suitable for cable suspension in the middle, and can save the trouble of cables passing through the center column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com