Targeting method for cooling nozzle

A technology for cooling nozzles and bullseye, which is used in liquid cooling, engine cooling, instruments, etc., can solve the problems of low target shooting efficiency of cooling nozzles, and achieve the effect of improving target shooting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

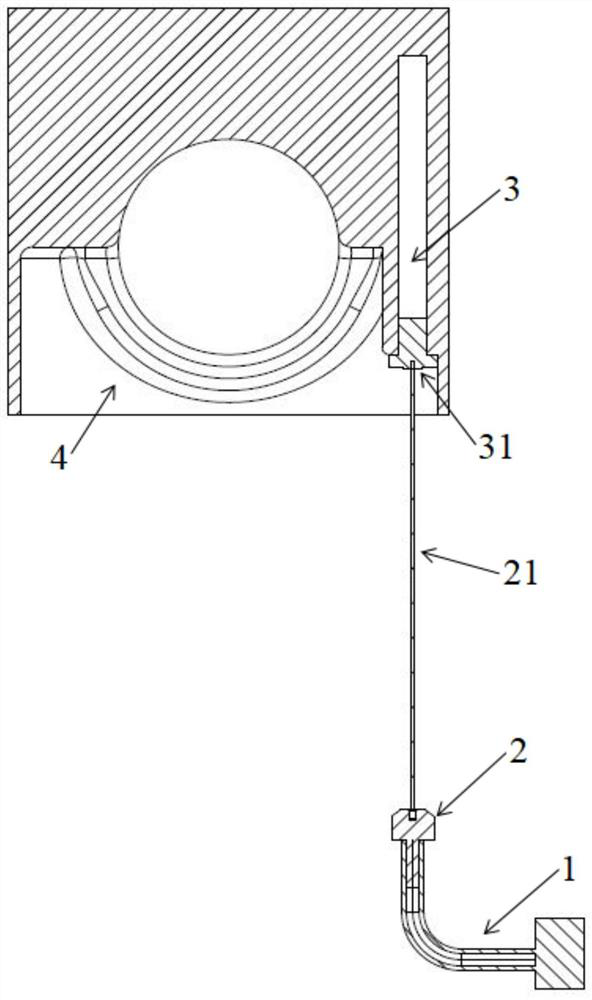

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

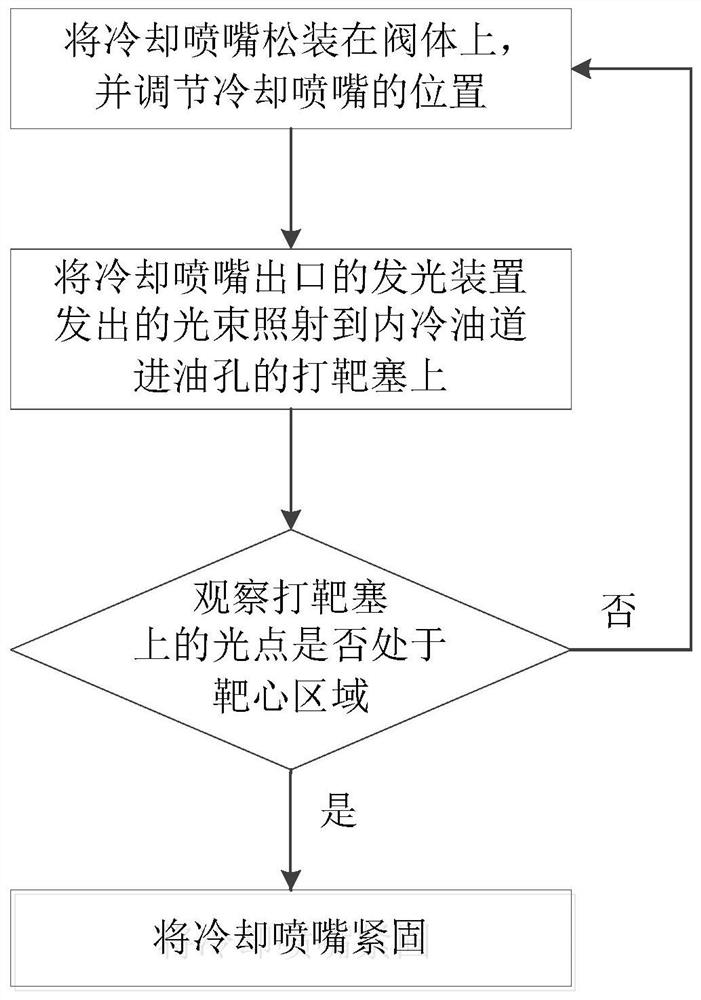

[0035] like figure 1 As shown, a kind of cooling nozzle shooting method provided by the present invention comprises:

[0036] S101. Design the cooling nozzle 1 so that the position of the cooling nozzle 1 relative to the valve body can be adjusted:

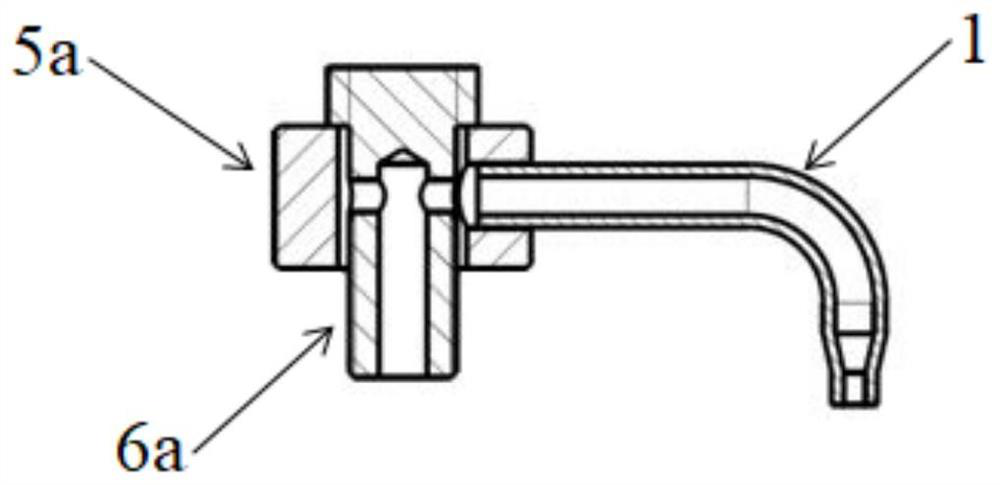

[0037] In one embodiment, the current hollow bolt type piston cooling nozzles all have positioning pins, which results in that the positional relationship between the valve body and the piston cooling nozzles is fixed and cannot be adjusted as long as the machining is completed. Specifically, as image 3 As shown, the cooling nozzle provided by the present invention is a hollow bolt type piston cooling nozzle. The cooling nozzle 1 does not have the structure of the positioning pin, and at the same time, the first valve body 5a and the first bolt 6a ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com