A device and method for double-sided precision shooting of hdi board

A double-sided and precise technology, applied in PCB positioning, printed circuit components, printed circuits and other directions in the processing process, can solve the problems of increasing the shooting time, positioning, and reducing the production efficiency of HDI boards, so as to improve the shooting efficiency and reduce the The effect of working strength and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

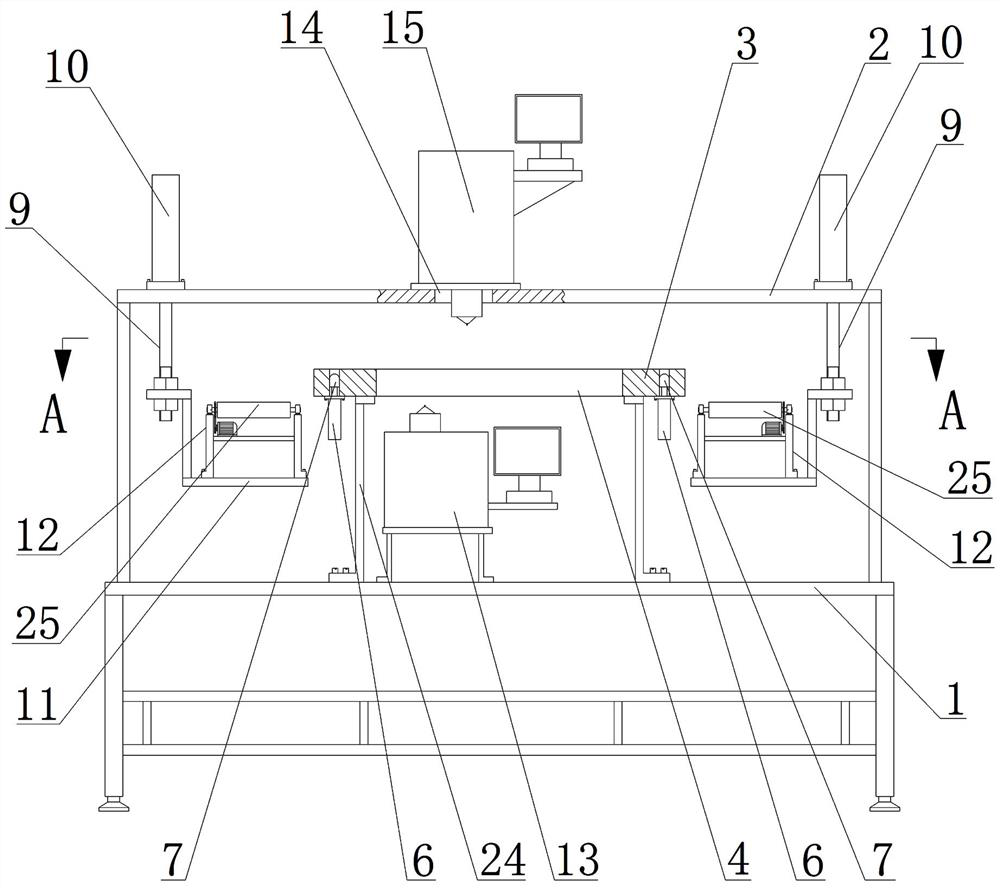

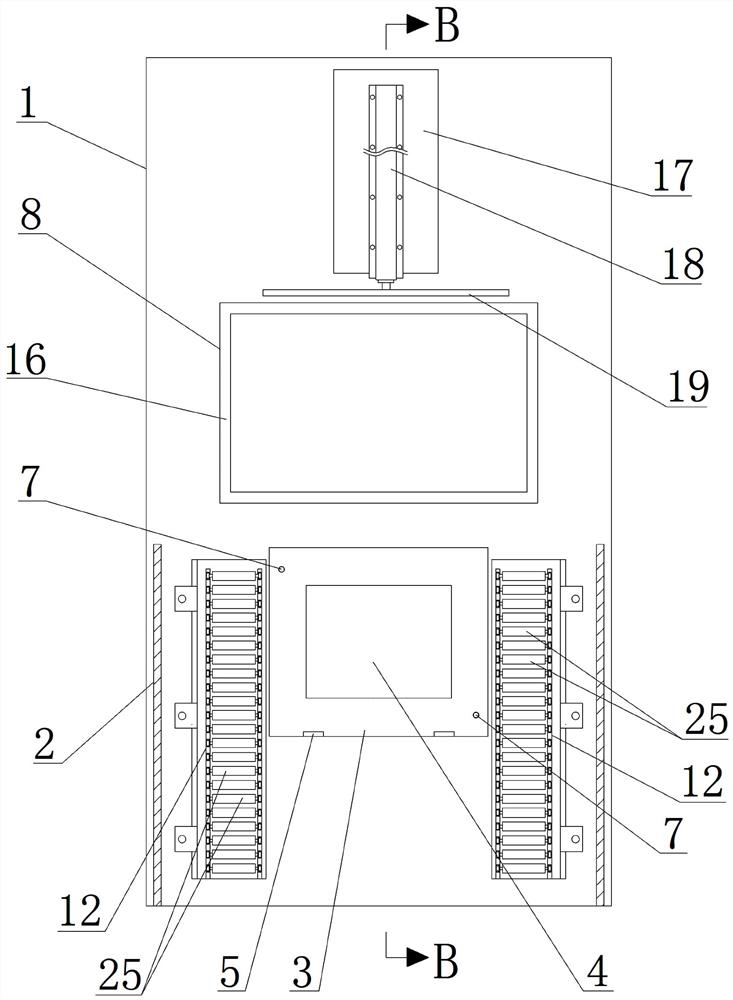

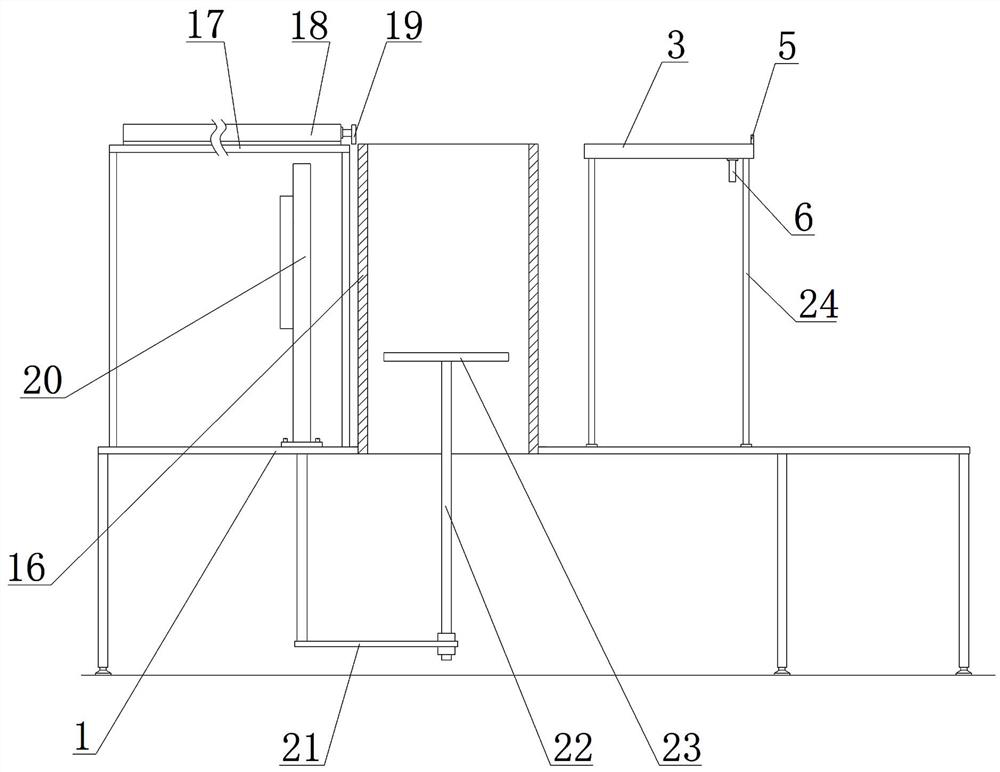

[0042]The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following:

[0043] like Figure 1~Figure 3 As shown, a device for double-sided precision shooting of HDI board, which includes a workbench 1, a gantry 2 fixed on the workbench 1, the bottom surface of the workbench 1 is fixed with a plurality of supports on the ground A positioning table 3 is arranged above the work table 1, a through slot 4 is opened in the middle of the positioning table 3, and a limit plate 5 is fixed on the top surface of the positioning table 3 and located on its front edge. The top surface of the table 3 is provided with two guide holes arranged diagonally, and a jacking cylinder 6 fixed on the positioning table 3 is arranged directly below the two guide holes. The working end of the piston rod of the jacking cylinder 6 A floating column 7 , which is slidably installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com