Installation structure of rolling door motor and installation method of rolling door motor

A rolling shutter door motor and installation structure technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of difficult installation of the motor, large force of the feet, and the impact of maintenance costs, so as to achieve convenient and fast installation, improve accuracy, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

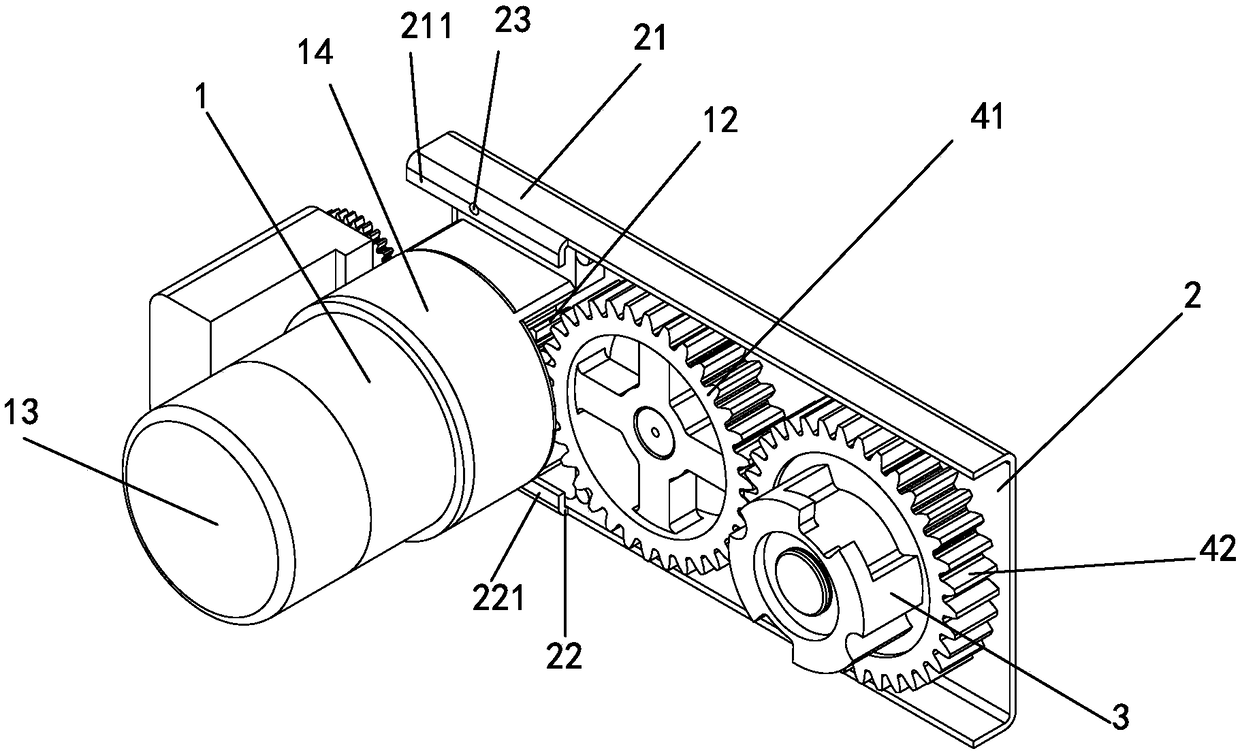

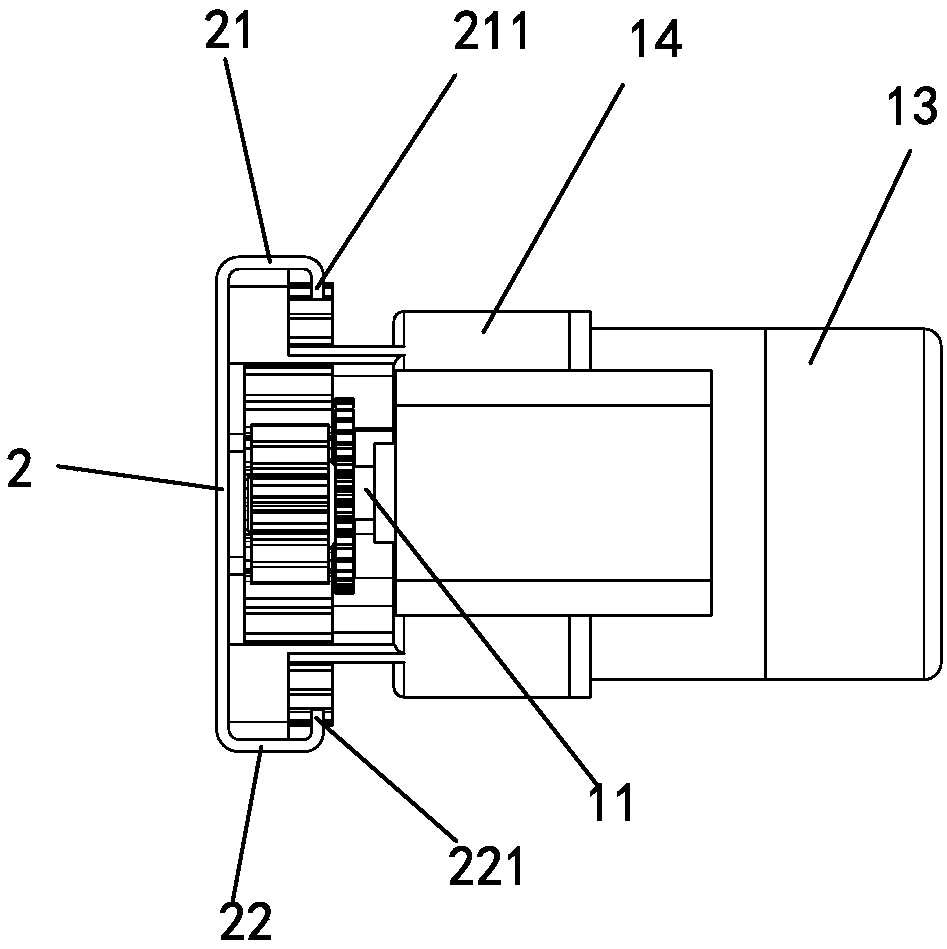

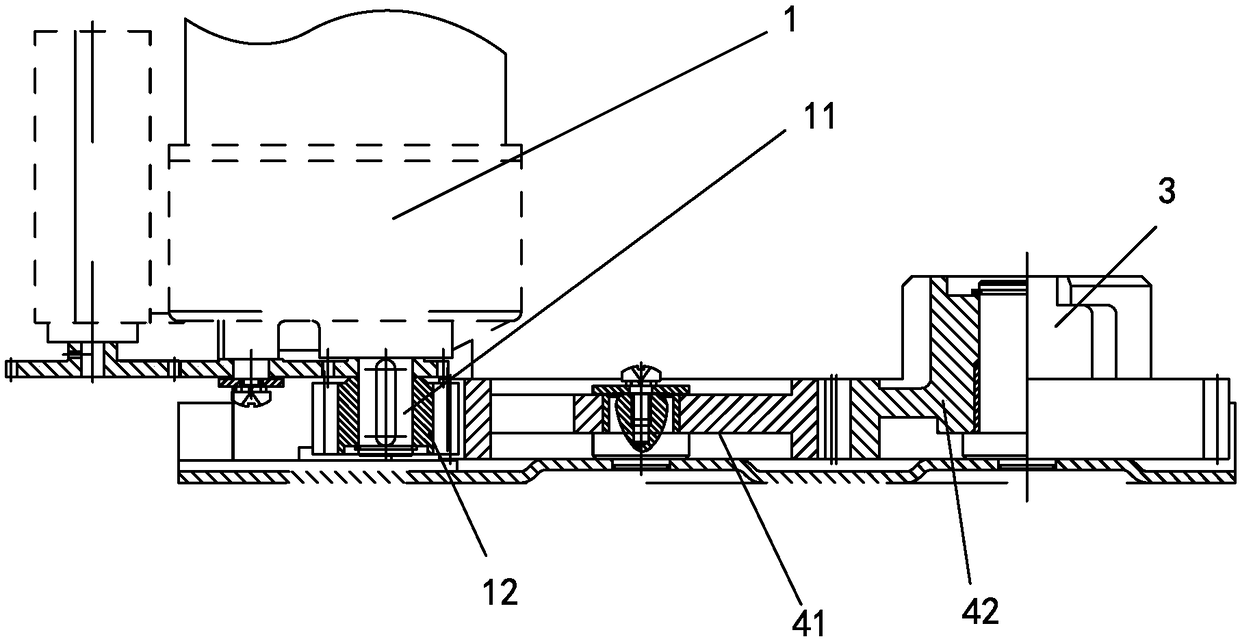

[0037] Embodiment one, see Figure 1 to Figure 3 As shown, the mounting structure of a rolling door motor of the present invention includes a motor 1, a mounting plate 2 and a reel gear 3, and the motor 1 and the reel gear 3 are respectively installed on the mounting plate 2, from the installation direction , the motor 1 and the reel gear 3 are installed on the left and right sides of the mounting plate 2 respectively. In this embodiment, the motor 1 refers to the motor assembly, which includes a driving motor 13 and a reduction box 14. The output shaft of the reduction box 14, that is, the output shaft 11 of the motor 1, is connected to the reel gear 3 through a transmission mechanism to drive the rolling door up and down. movable; the mounting plate 2 is provided with an upper positioning block 21 and a lower positioning block 22 corresponding to the position of the motor 1, and the bottom of the motor 1 is positioned and mounted on the mounting plate 2 through the upper and...

Embodiment 2

[0042] Embodiment two, see Figure 4As shown, the difference between this embodiment and Embodiment 1 is that: the upper positioning block 21 and the lower positioning block 22 are respectively a right-angled structure; one side of the right-angled part is perpendicular to the mounting plate 2 to form the upper and lower parts of the motor respectively. The other side of the positioning surface is parallel to the mounting plate 2 to form upper and lower limiting surfaces to prevent the motor from coming out, and the two right-angle parts are oppositely arranged; the motor 1 is installed in the slot formed by the two right-angle parts. The opposite sides of the upper and lower positioning blocks are parallel to each other. In addition to the shape of the right-angled piece, other connecting pieces that are not in a right-angled relationship are also applicable, as long as they can form the upper and lower positioning surfaces of the motor and the upper and lower limiting surfac...

Embodiment 3

[0043] Embodiment three, see Figure 5 As shown, the difference between the present embodiment and the second embodiment is that the opposite sides of the upper and lower positioning blocks 21 and 22 gradually approach along the traveling direction of the motor 1 . The mounting plate 2 is provided with a limiting member 24 of the motor 1 for accurate positioning and installation of the motor 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com