Film pressing and edge sealing combined mechanism for paddy field film laminating machine

A technology of laminating machine and edge combination, which is applied in the fields of plant protective cover, botany equipment and method, gardening, etc., can solve the problems of difficult configuration of lamination parts and edge sealing parts, difficult guarantee of operation quality, poor operation effect, etc. Achieve the effect of simple and convenient configuration and installation, novel structure and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

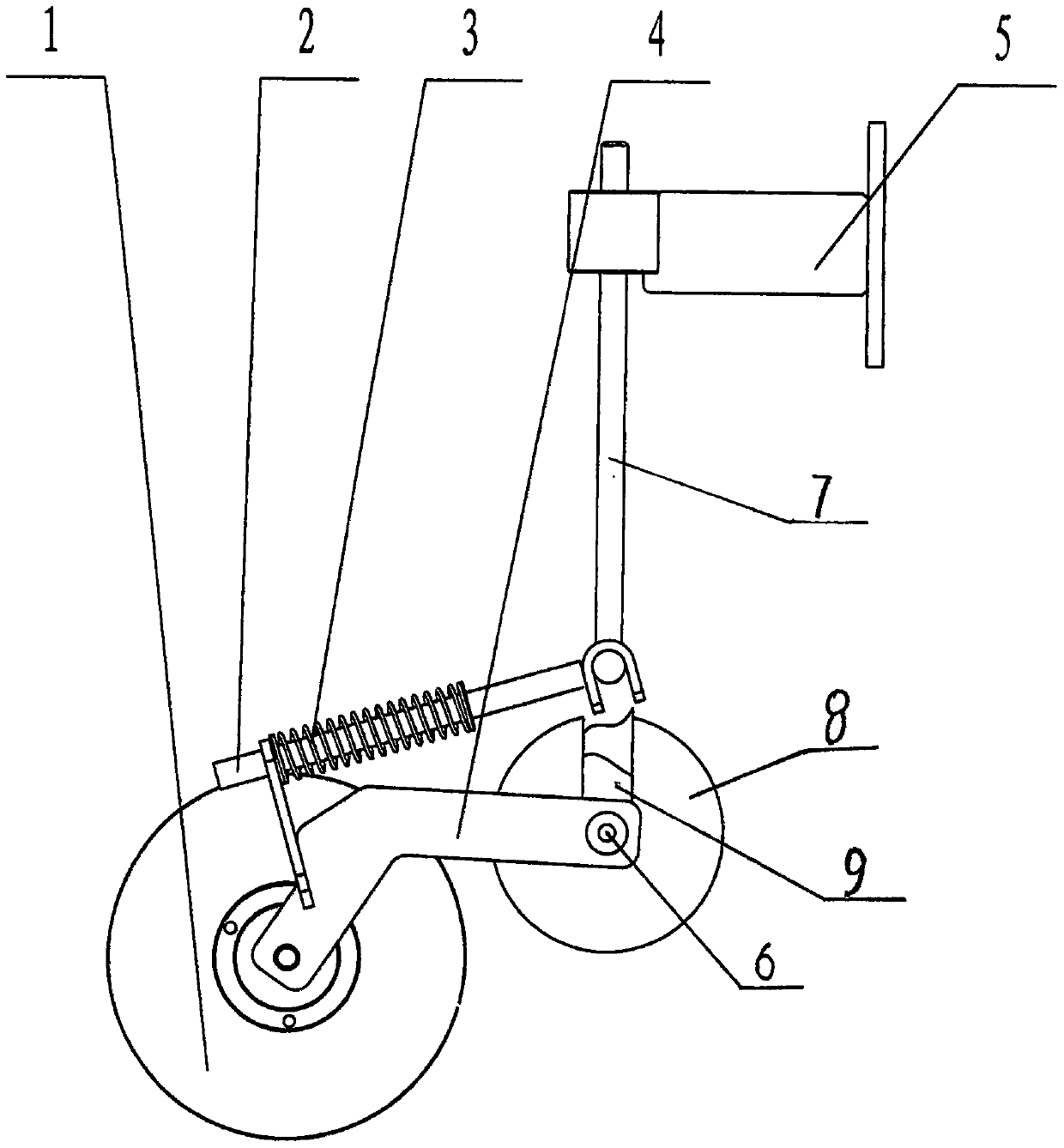

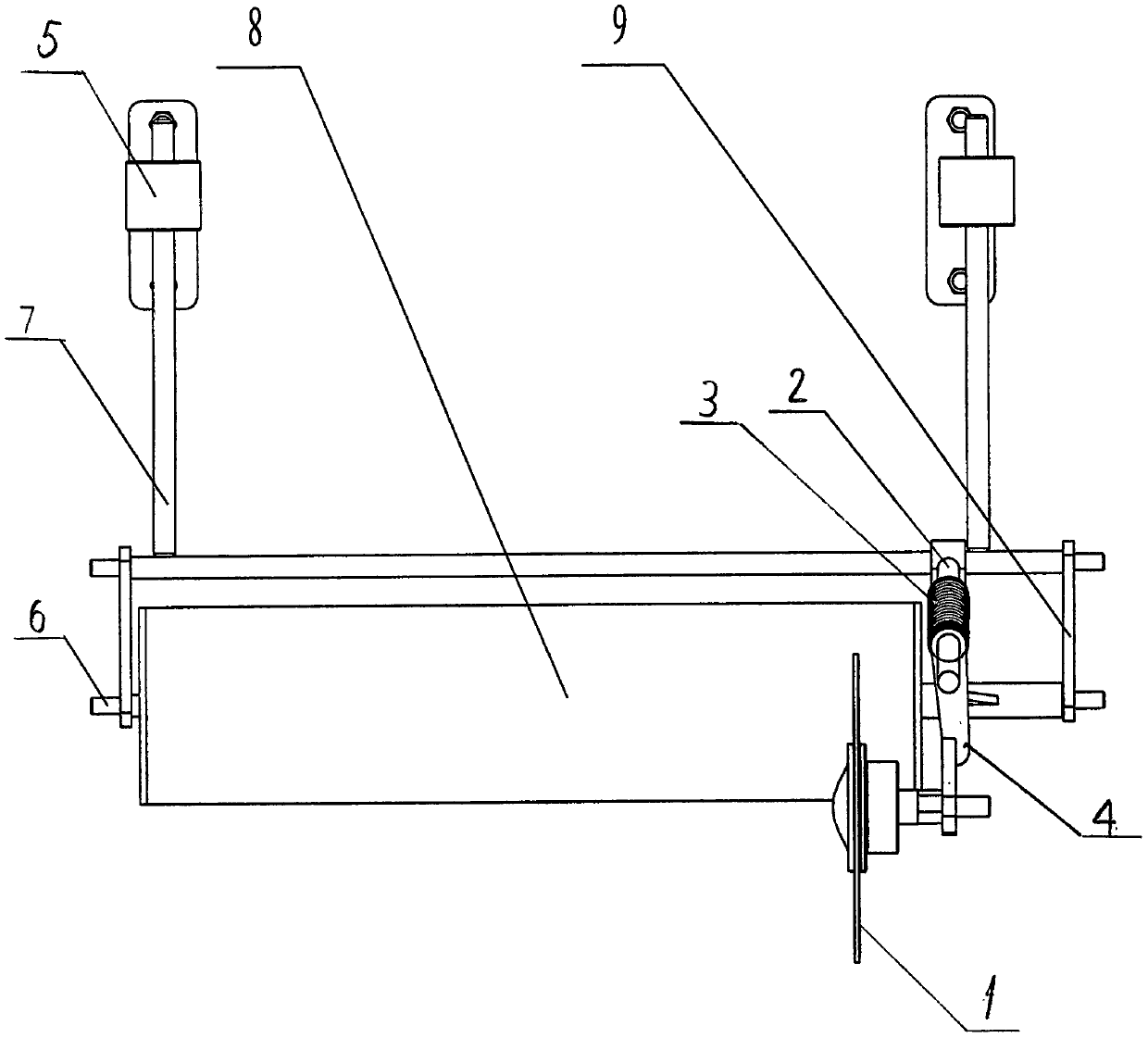

[0010] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. A combination mechanism of film pressing and edge sealing of a paddy field laminator, a mounting frame 7 that can be moved up and down to adjust on two mounting seats 5 that are symmetrically arranged with each other, is installed on the lower side of the mounting frame 7 by two pieces The plate 9 hangs and installs the lamination roller assembly 8, and the connecting plate 4 is hingedly mounted on the end of the roller shaft 6 side of the laminating roller assembly 8, and the connecting plate 4 is rotatably fitted. Edge banding wheel assembly 1, on the connecting plate 4, a plug-in profile control rod 2 that can be moved axially telescopically, the front end of the profile control rod 2 is hingedly connected with the mounting frame 7, and the profile control rod 2 It can swing in a vertical direction around its hinge point with the mounting frame 7. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com