Camera Layout and Calibration Method for Improving the Measurement Accuracy of Depth of Field

A calibration method and measurement accuracy technology, which is applied in image data processing, instruments, calculations, etc., can solve the problems of low measurement accuracy, achieve the effect of improving calibration accuracy, solving low measurement accuracy and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

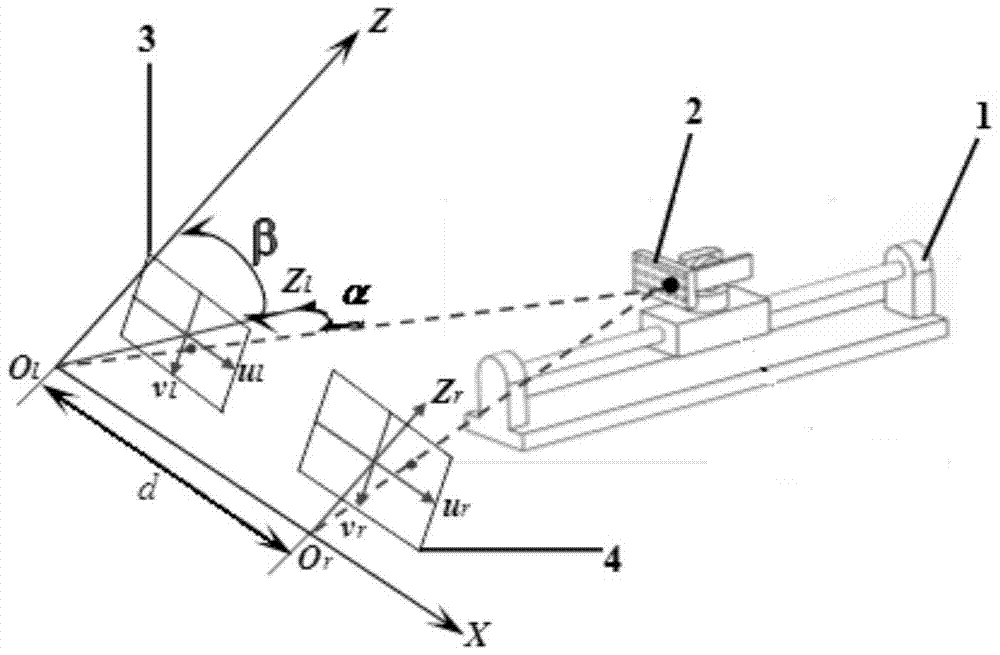

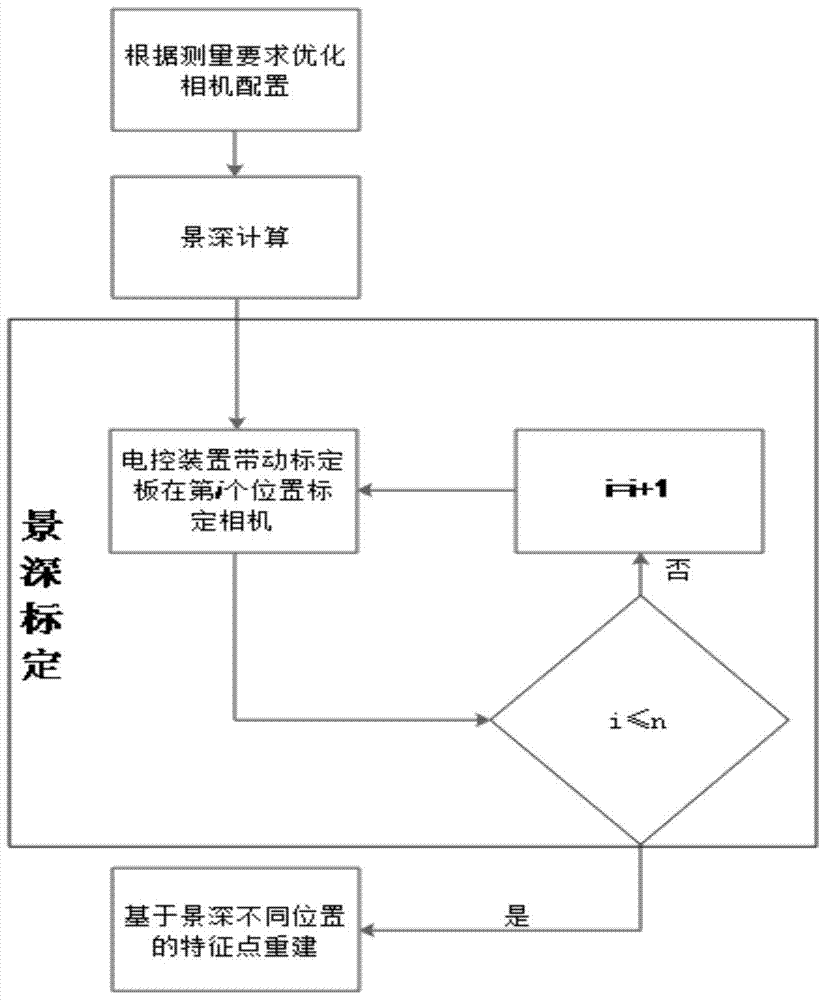

[0037] attached figure 1 Camera layout and calibration system diagram for improving depth of field measurement accuracy. The embodiment selects Zhuoli Hanguang high-precision electronic control device 1. The high-precision electronic control device 1 of the present invention can realize linear motion in one direction, with a linear stroke of 500mm, 360° rotation around the horizontal axis, and 360° around the vertical axis. rotate. The size of the high-precision two-dimensional plane calibration plate 2 used in the calibration process is 300mm×400mm, and the characteristic mark points on the calibration plate 2 are circular mark points, and the diameter of the circular mark points is 30mm, a total of 30, of which the calibration plate 2 Arrange 6 horizontally and 5 vertically. The selected left and right cameras 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com