Food-grade raw material circulation and sterilization channel system

A food-grade, channel technology, applied in the field of food-grade raw material circulation sterilization channel system, can solve problems such as cross-contamination, affecting food quality, and failing to meet sterilization standards, ensuring hygiene and safety and reducing the probability of cross-contamination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

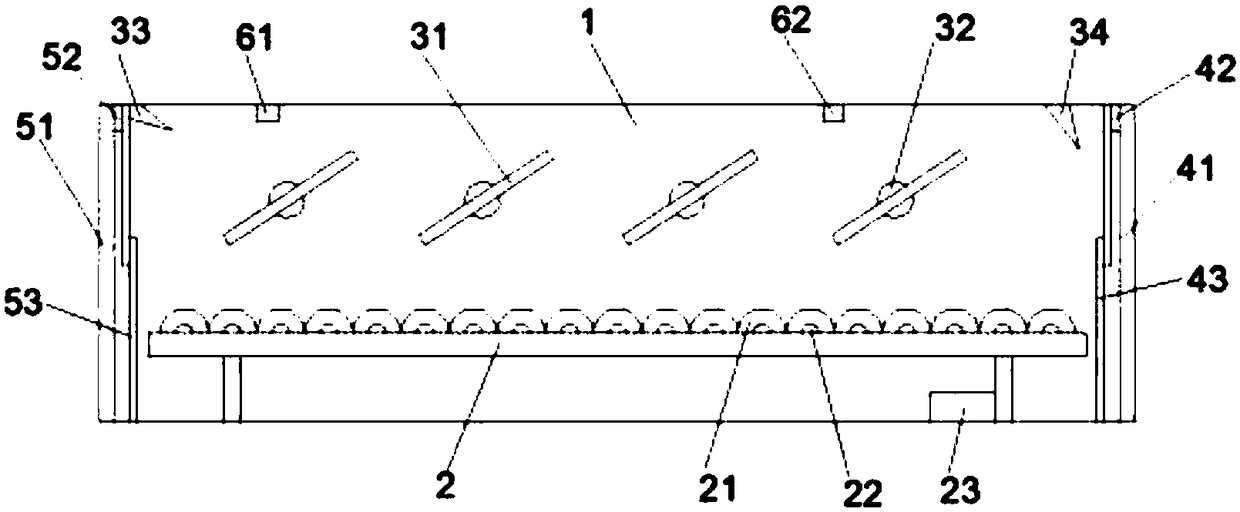

[0022] An embodiment of the present invention will be described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, a food-grade raw material circulation sterilization channel 1 system includes a channel 1, a conveying device 2, a material inlet, a material outlet, a sterilizing device and an induction device. The conveying device 2 is arranged in the center of the channel 1 for transferring materials. The material inlet and material outlet are set at both ends of the channel 1. The material enters from the material inlet and is discharged from the material outlet under the transmission of the conveying device 2. The sterilizing device and the sensing device are arranged on the inner wall of the channel 1. The sterilizing device is used for All components in channel 1 are sterilized in real time, including the original equipment in channel 1 and the materials being transported. The sensing device is used to monitor the environment of channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com