Tool box for repair of crane

A technology for cranes and toolboxes, which is applied in the field of toolboxes for crane maintenance, which can solve the problems of maintenance personnel's mistakes and potential safety hazards, and achieve the effect of avoiding manual opening of the box cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further detailed explanation through specific implementation mode below:

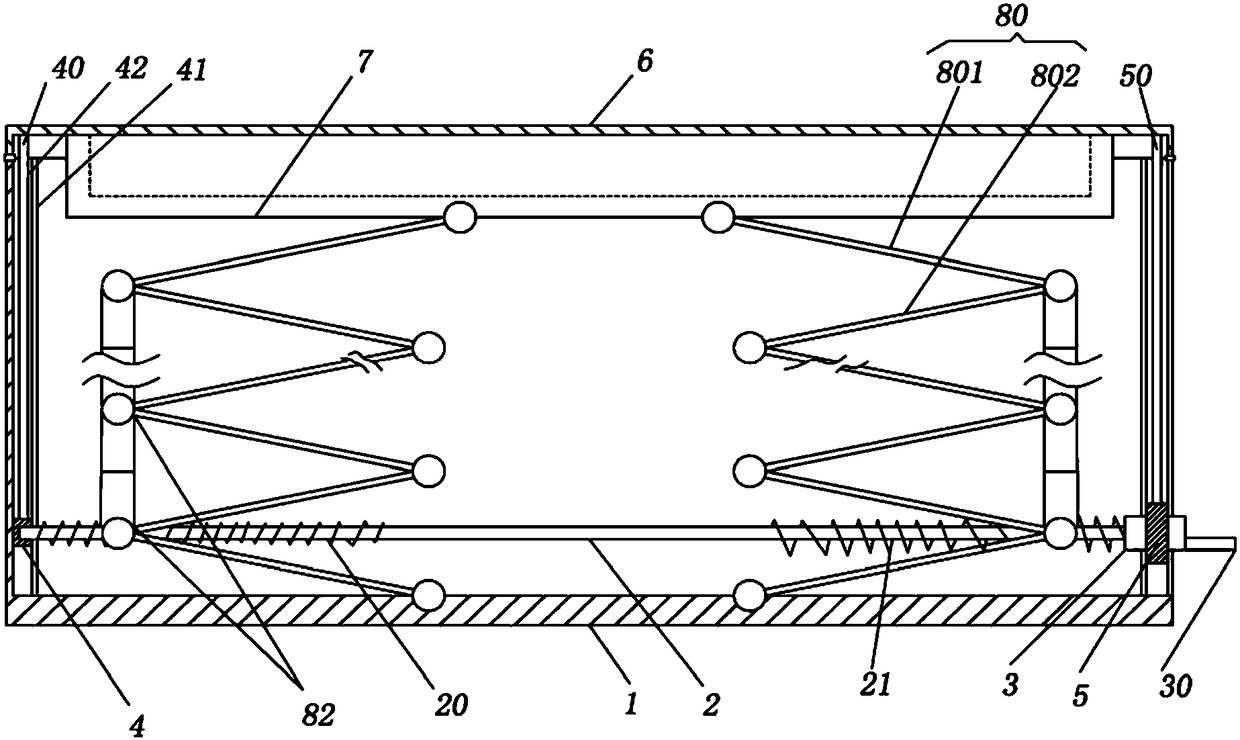

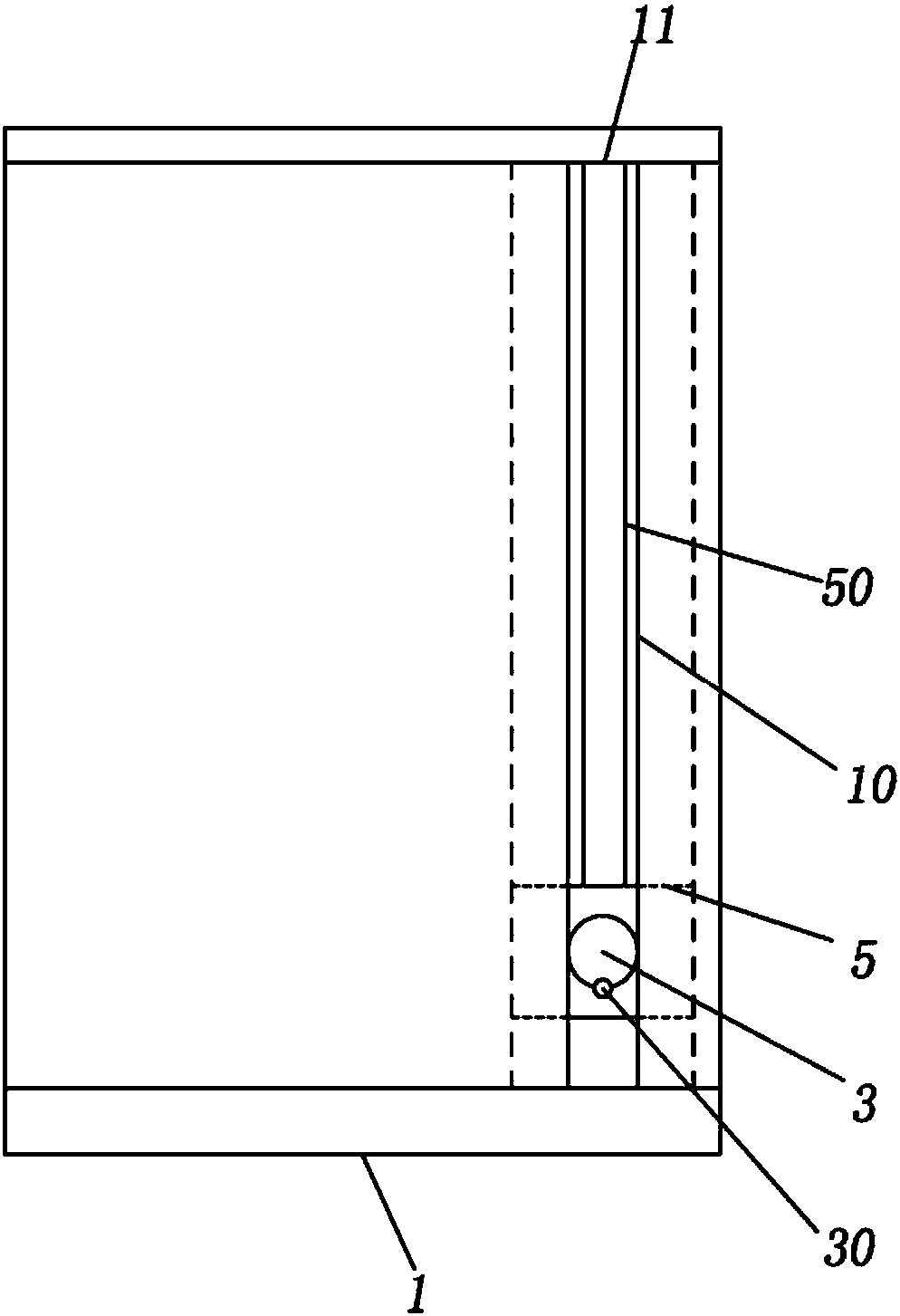

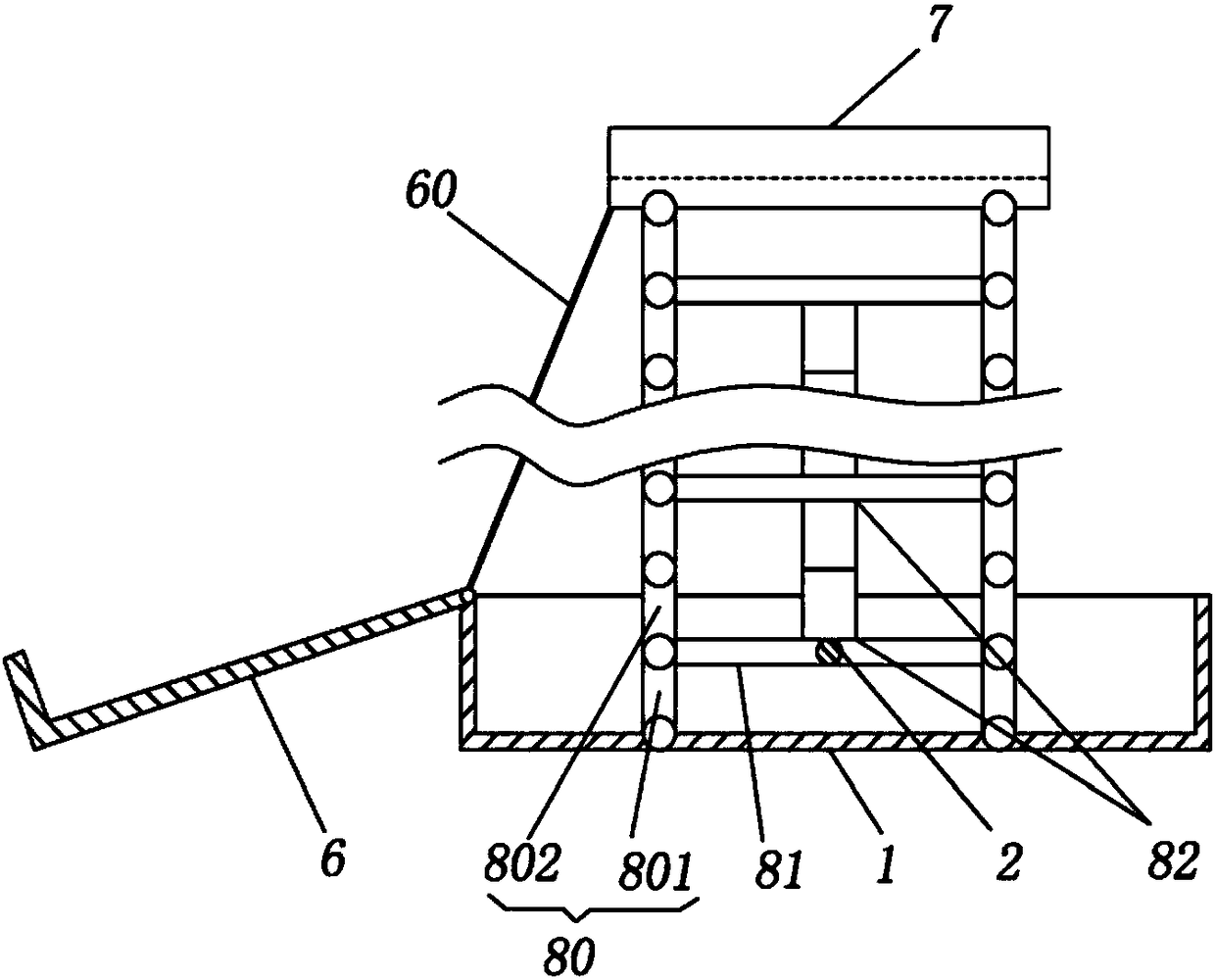

[0018] The reference signs in the accompanying drawings of the specification include: box body 1, movable joint 10, limit bar 11, screw rod 2, thread section one 20, thread section two 21, drum 3, handle 30, main slider 4, main Ejector 40, sandwich plate 41, chute 42, auxiliary slider 5, auxiliary ejector 50, box cover 6, sliding cloth 60, tool table 7, lifting frame 8, corner rod group 80, first rod 801, second Rod 802, control rod 81, telescoping rod 82.

[0019] The embodiment is basically as figure 1 Shown: a toolbox for crane maintenance, including a box body 1 and a box cover 6 for covering the box body 1, and the box body 1 and the box cover 6 are rotatably connected. The box body 1 is provided with a rotating mechanism, a push rod mechanism, a lifting mechanism and a tool table 7 . Maintenance tools can be placed in the casing 1 and on the tool table 7 .

[0020] Such as figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com