Drilling device for valve machining

A drilling device and valve technology, applied in metal processing, etc., can solve the problems of complex structure and operation, affecting the performance of the drilling device, and not being simple and convenient to use, so as to achieve easy operation and use, flexible structure adjustment, and improved use performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

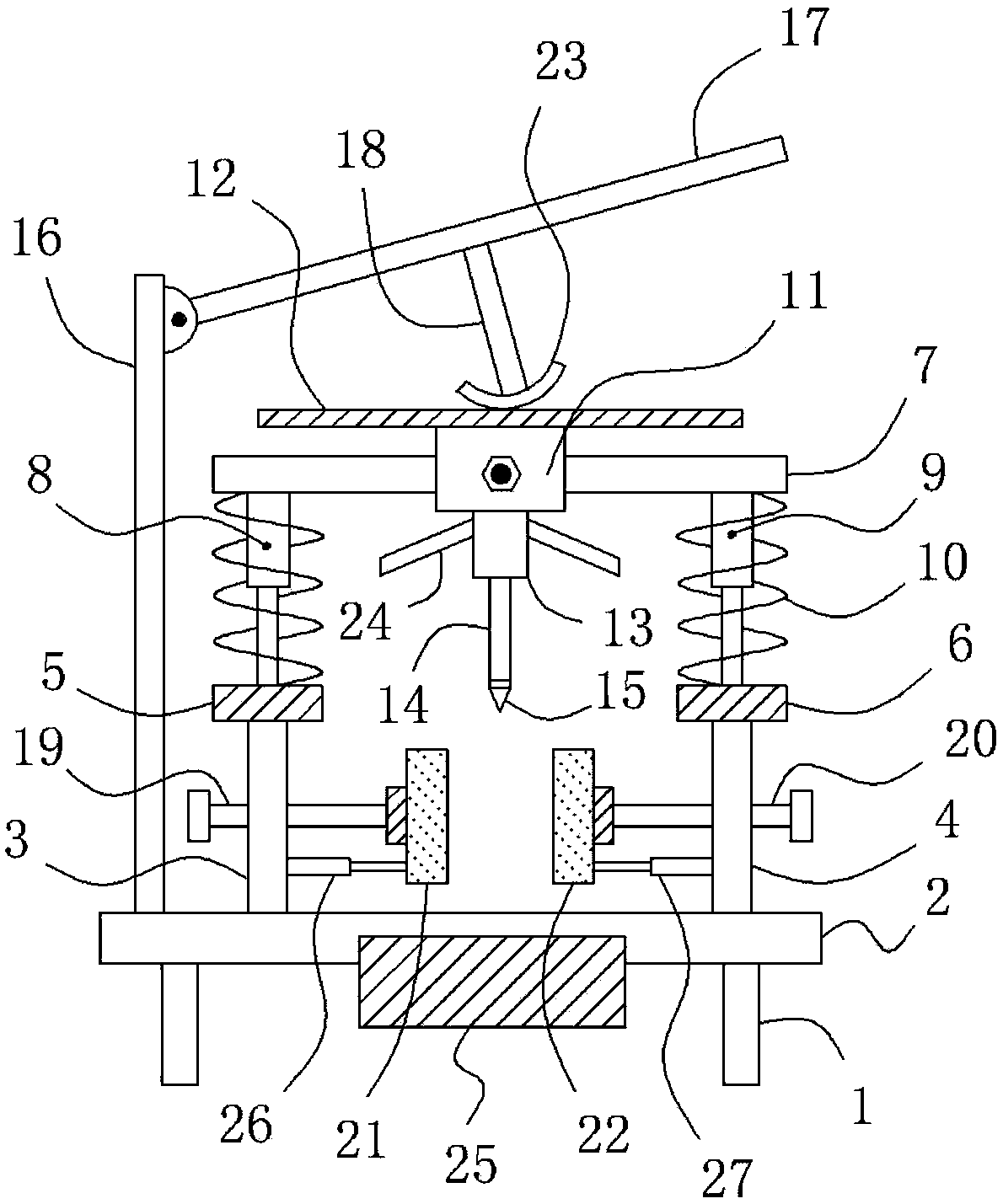

[0017] like figure 1 As shown, a drilling device for valve processing includes a bracket 1 and a base 2 arranged on the bracket 1, and a left fixing seat 3 and a right fixing seat 4 are respectively arranged on the base 2, and the left fixing seat 3 and the right fixing The top of the seat 4 is respectively provided with a left top seat 5 and a right top seat 6, and a horizontally arranged slide bar 7 is also provided above the left top seat 5 and the right top seat 6. The cross-sectional shape of the slide bar 7 is a square, and The left end of slide bar 7 and the left top seat 5 are also connected with vertically arranged left vertical telescopic link 8, between the right end of slide bar 7 and the right top seat 6, also connected with vertically arranged right vertical telescopic link 9 , while the outside of the left vertical telescopic rod 8 and the right vertical telescopic rod 9 are also provided with coil springs 10;

[0018] The slide bar 7 is also sleeved with a sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com