Grooved round nut with variable tooth type anti-loosening thread

A round nut and changing tooth shape technology, applied in the direction of nuts, threaded fasteners, screws, etc., can solve the problems of insufficient locking force and easy loosening of slotted round nuts, and achieve the effect of stable clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described now in conjunction with accompanying drawing.

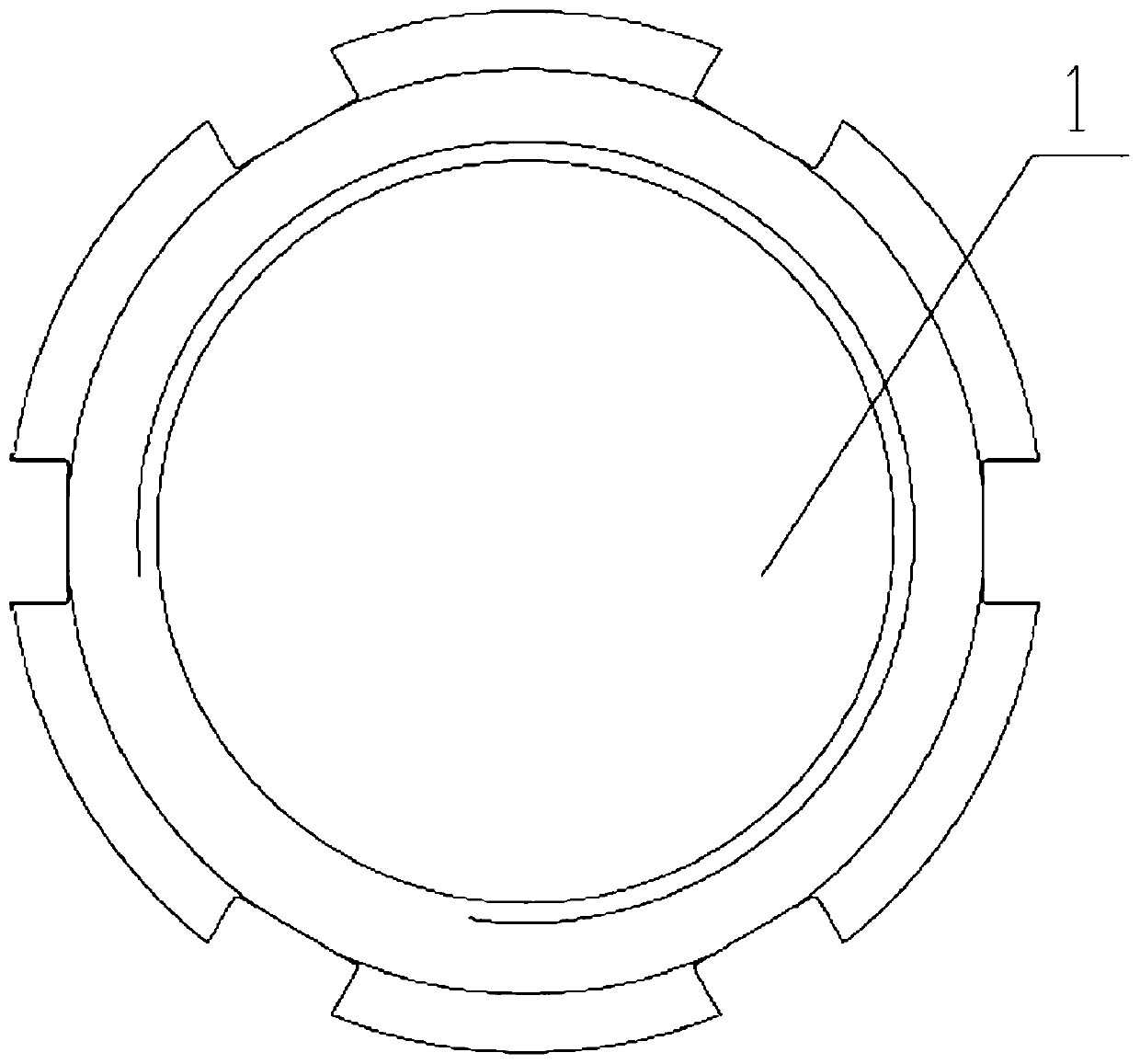

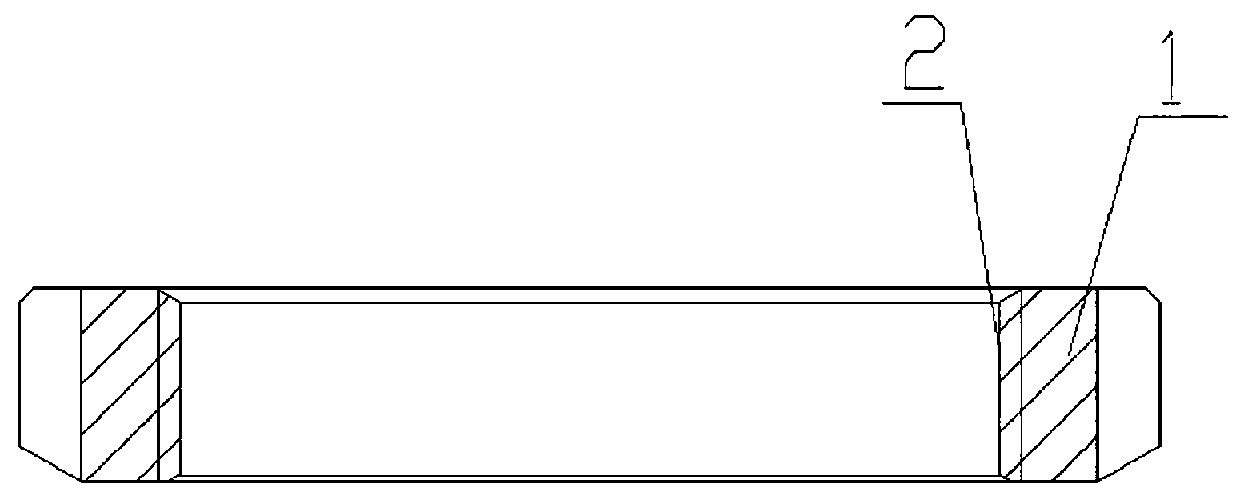

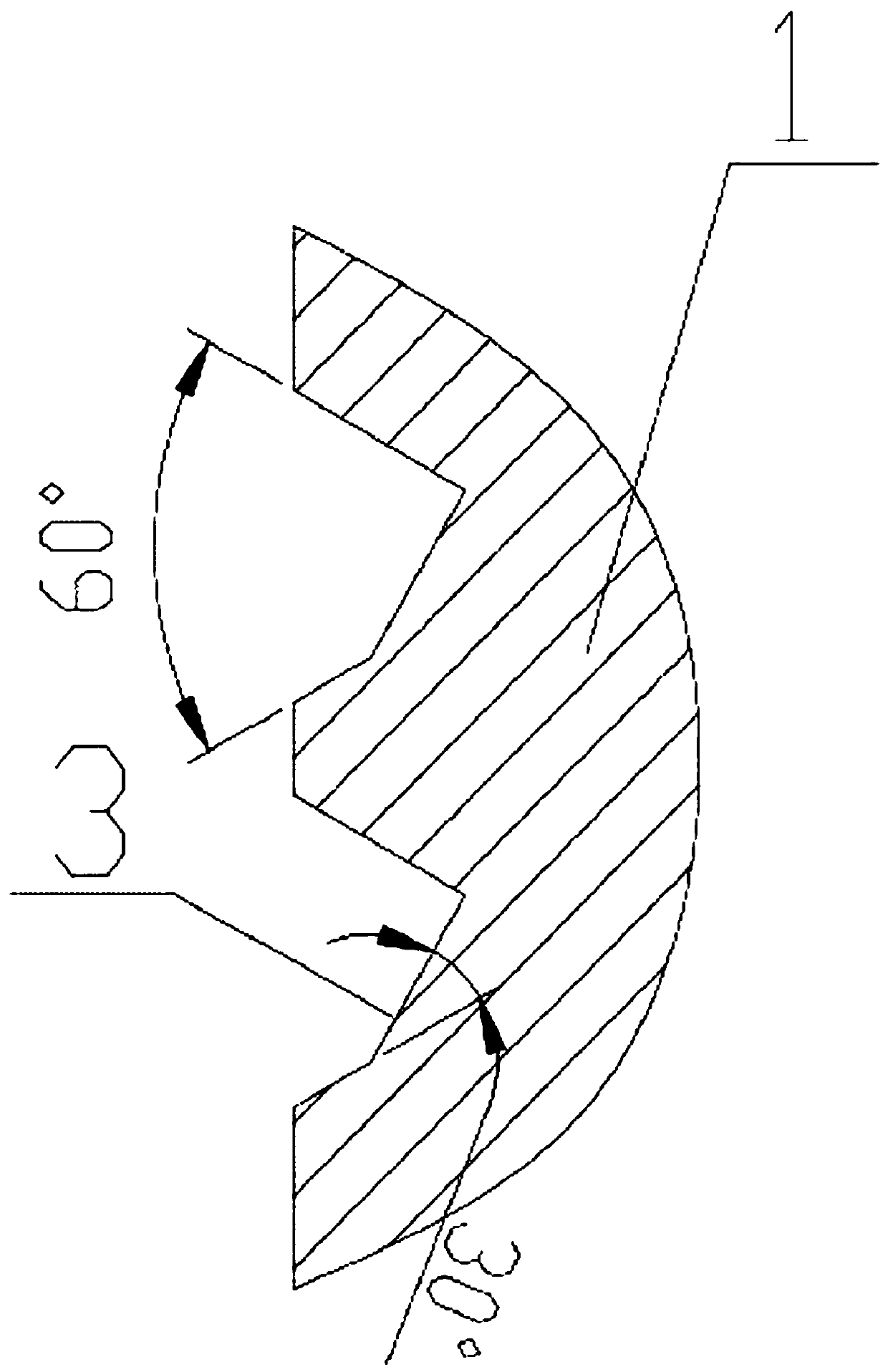

[0016] see figure 1 , figure 2 with image 3 , the present invention designs a slotted round nut provided with variable-tooth-type anti-loosening threads, including a slotted round nut body and a slotted round nut internal thread. There is a wedge-shaped slope 3 at the bottom of the slotted round nut internal thread 2 of the slotted round nut body 1, and the angle between the wedge-shaped slope 3 and the reverse extension line of the lower plane of the slotted round nut internal thread 2 is 30° . The angle between the lower plane and the upper plane of the slotted round nut internal thread 2 is 60°. A phosphating layer is provided on the surface of the internal thread 2 of the slotted round nut, and a phosphating layer is provided on the surface of the wedge-shaped slope 3 . The slotted round nut body 1 is a slotted round nut with a specification of M60×1.5mm.

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com