Novel assembly type ancient building production device

A production device and prefabricated technology, applied in ceramic forming cores, ceramic forming mandrels, climate sustainability, etc., can solve the problems of long-term cement towers, easy peeling, cracking, etc., and achieve fast overall forming and construction. The effect of short cycle and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

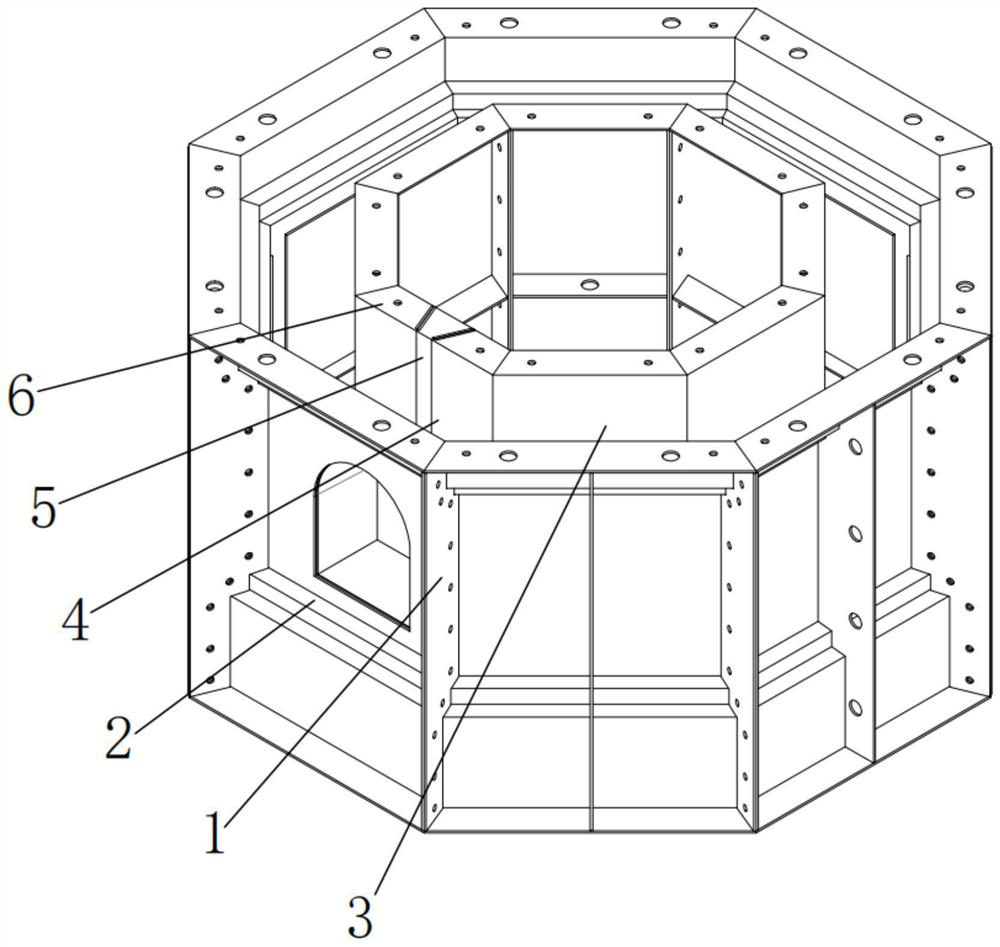

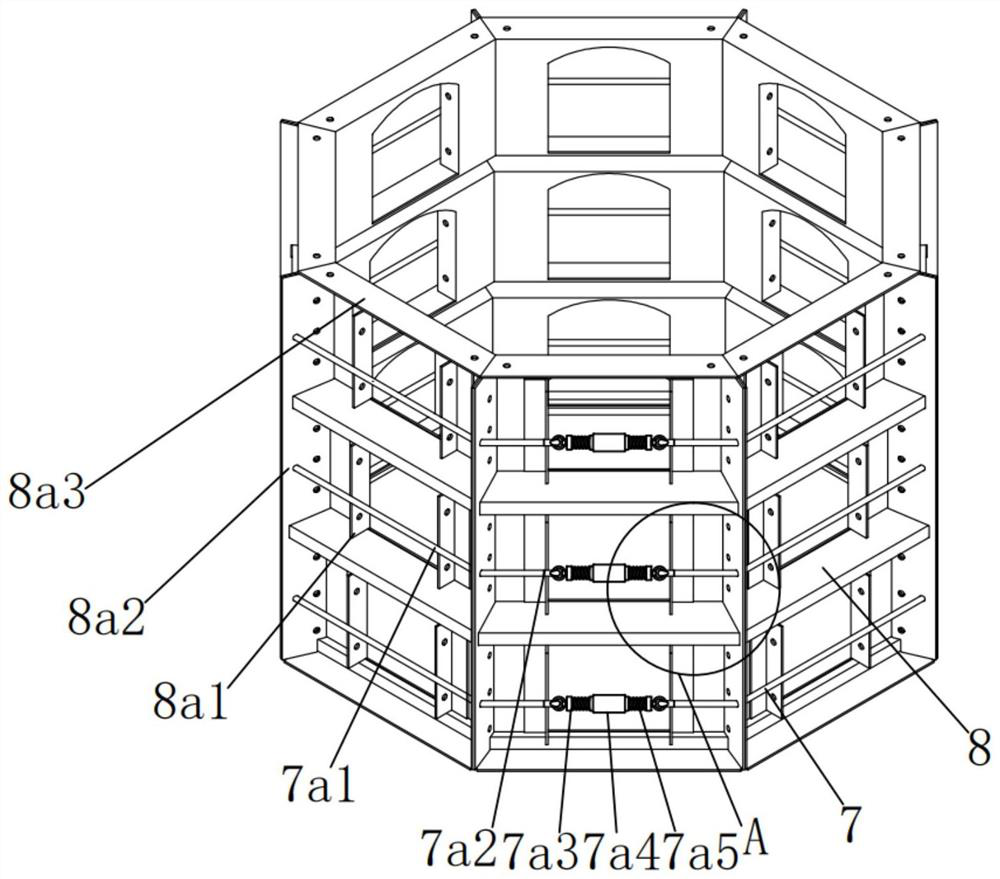

[0023] see Figure 1-8 , the present invention provides a technical solution: a new type of assembly type ancient building production device, comprising a tower base outer mold 1, a tower opening outer mold 2 and a tower body 8, a tower outer mold 1, and a tower opening outer mold 2. The inner side of the tower seat 3 is installed on the inner side, and the front side of the inner side of the tower seat 3 is installed with the first tower seat inner side module splitting block 4, the second tower seat inner side module splitting block 5 and the third. The inner side module of the tower base is divided into blocks 6, and an auxiliary component 7 is installed inside the outer wall of the tower body 8;

[0024] Through the cooperation between the outer mould 1 of the tower base, the outer mould 2 of the opening of the tower base, the inner mould 3 of the tower base and the tower body 8, a prefabricated cement tower is produced. First, because the prefabricated cement tower adopts...

Embodiment 2

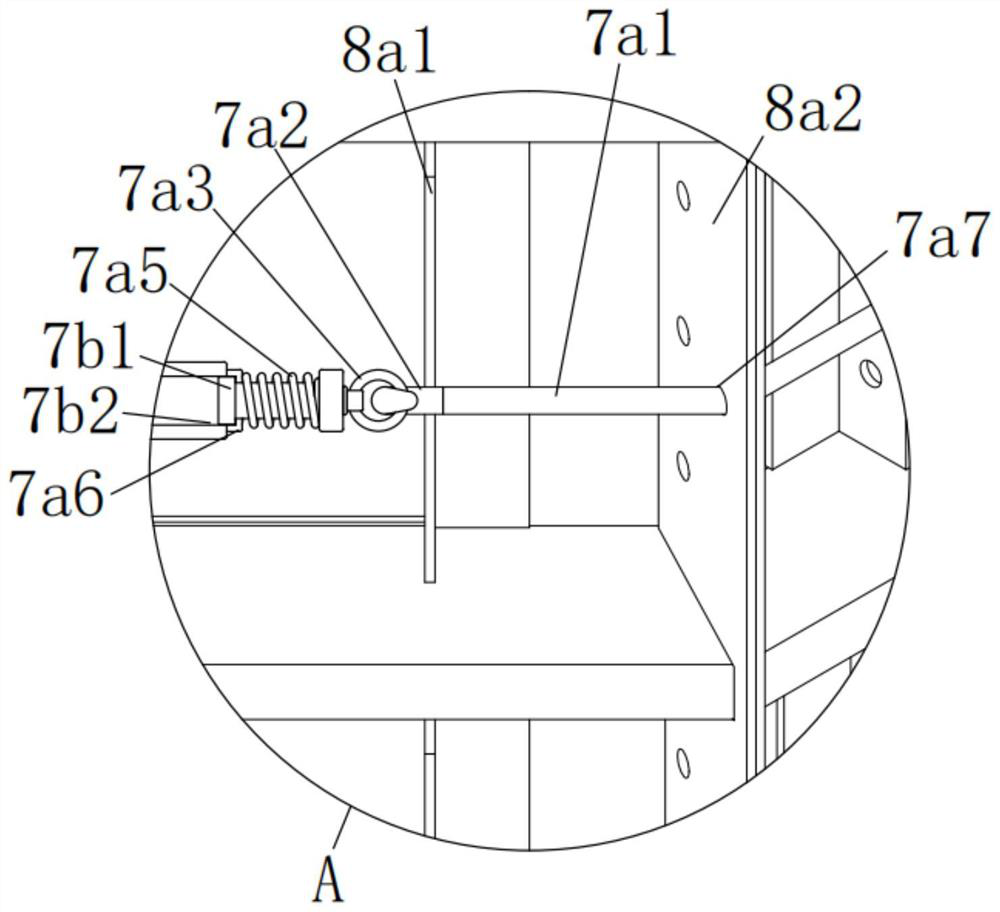

[0034] see Figure 1-8 , the present invention provides a technical solution: wherein the auxiliary assembly 7 further includes a slider 7a1 and a sliding groove 7a2, the sliding block 7a1 is respectively fixed to the inner ends of the collars 703 on both sides, and the sliding block 7a1 is slidably connected to the inside of the sliding groove 7a2 On both sides, the sliding groove 7a2 can limit the position of the slider 7a1, and the sliding groove 7a2 is processed on the inner inner wall of the sleeve 706;

[0035] Through the cooperation between the sleeve 703, the sliding block 7a1 and the sliding groove 7a2, the collar 703 can drive the sliding block 7a1 to move outward. Due to the sliding cooperation between the sliding block 7a1 and the sliding groove 7a2, the limit position of the sliding block 7a1 is made. The limitation is obtained, which avoids the problem that the wire rope 701 is only limited by the spring and has no limit position limiting ability.

[0036] work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com