Method for delaying frosting on surface of absorption type unit heat exchanger

A fin type heat exchanger and heat exchanger technology, which is applied in the directions of refrigerators, refrigeration components, lighting and heating equipment, etc., can solve the problems of poor operation effect of absorption units, and achieve low cost, delaying frost formation, and difficulty in frosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

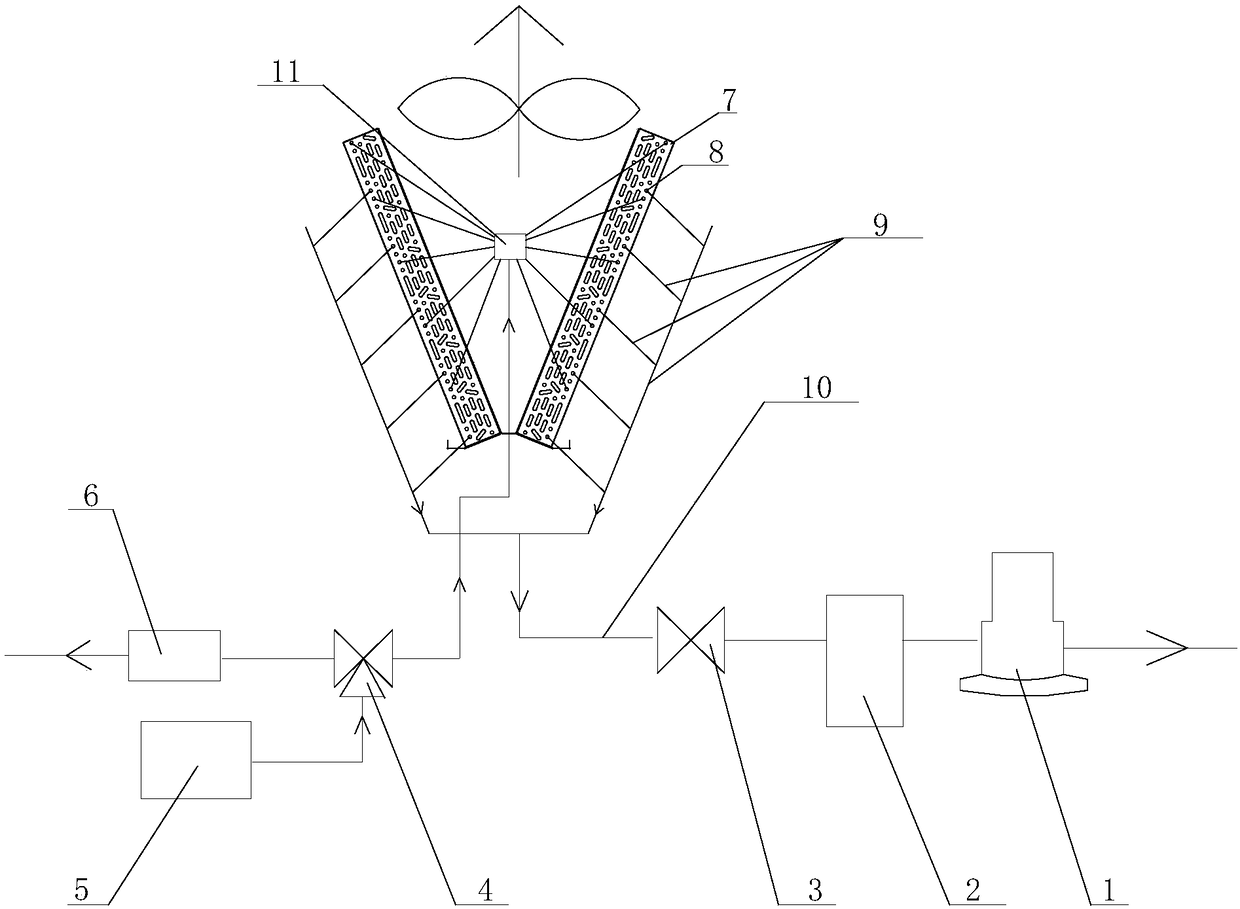

Method used

Image

Examples

Embodiment 1

[0045] The method for delaying frosting on the surface of the heat exchanger of an absorption unit by using the above-mentioned device is as follows: the concentrated solution used is a concentrated ammonia solution with an ammonia content of 20%.

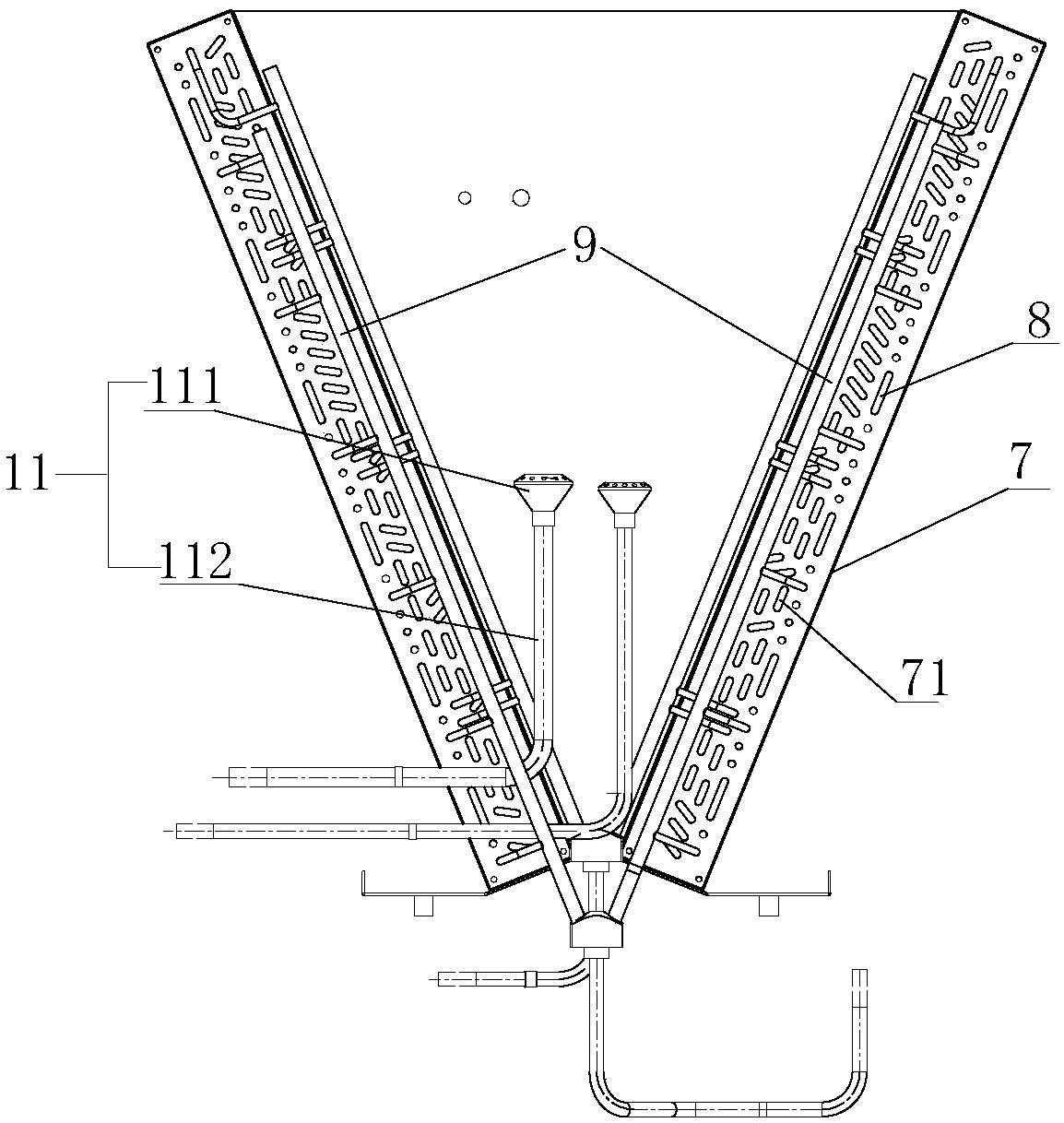

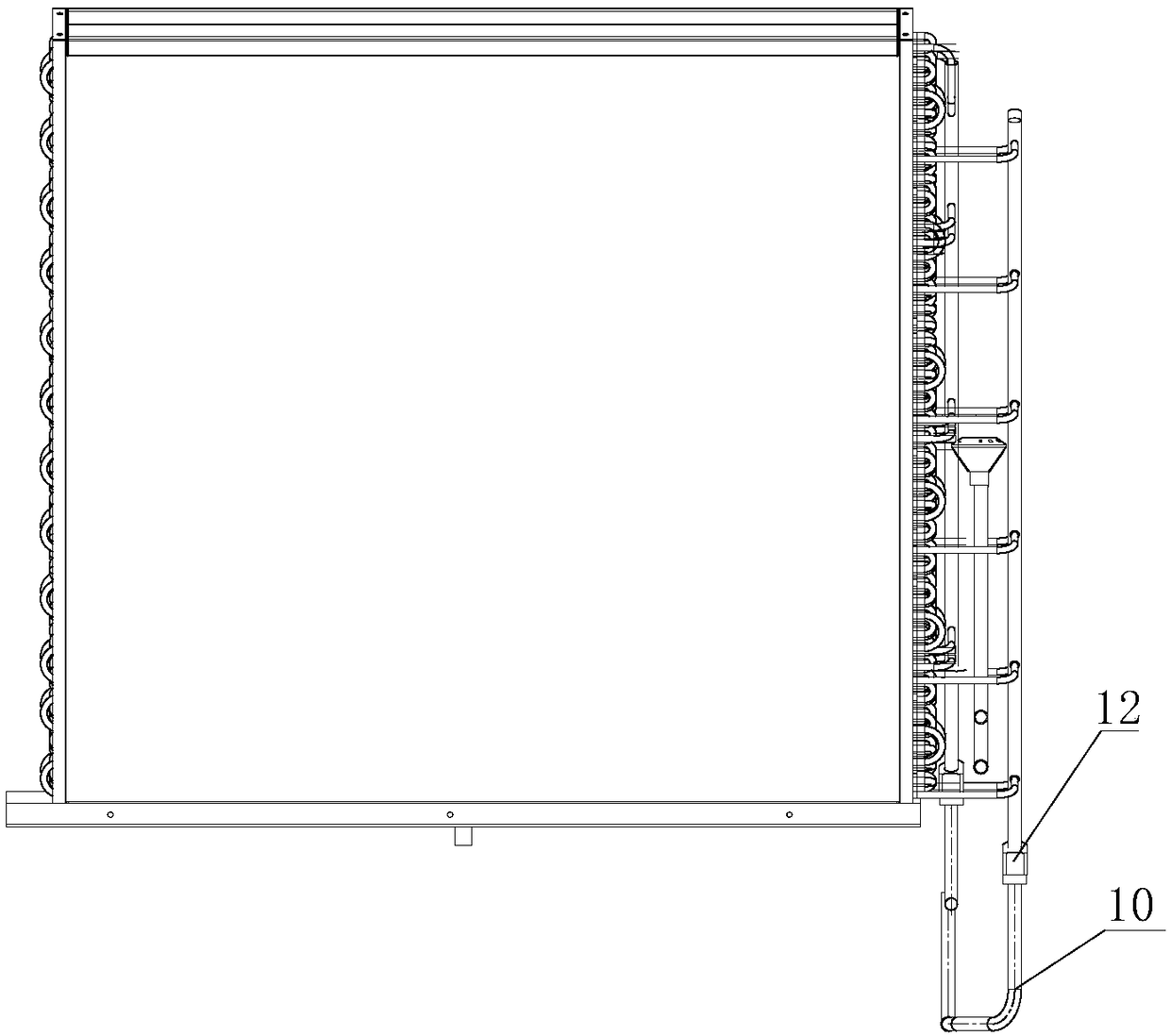

[0046] When the heat pump unit starts to work, the electromagnetic three-way valve 4 is connected to the valve of the liquid separator 11, and the concentrated ammonia solution enters the liquid dispenser 111 in the liquid dispenser 11 through the electromagnetic three-way valve 4, and the liquid dispenser 111 displaces the concentrated ammonia. The solution is evenly distributed to each branch, and enters the defrosting coil 8 inside and outside the finned heat exchanger, and the flow rate of the concentrated ammonia solution is 100g / min.

[0047]At this moment, the surface temperature of the defrosting coil 8 is higher than that of the heat exchange coil 71 , and the heat exchange between the defrosting coil 8 and the heat exchang...

Embodiment 2

[0051] The defrosting method of this embodiment is the same as that of Embodiment 1. The difference from Embodiment 1 is that the concentrated solution used in this embodiment is a concentrated ammonia solution with an ammonia content of 50%, and its freezing point is around -80°C. The flow rate of the concentrated ammonia solution is 400g / min, and the time for passing the concentrated ammonia solution is 3 minutes, and the concentrated ammonia solution is continuously passed after an interval of 30 minutes, and adjusted according to the ambient temperature.

Embodiment 3

[0053] The defrosting method of this embodiment is the same as that of Embodiment 1. The difference from Embodiment 1 is that the concentrated solution used in this embodiment is a concentrated ammonia solution with an ammonia content of 15%, and its freezing point is between -30°C. The flow rate of the concentrated ammonia solution is 500g / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com